What is a hammer drill and how does it work

How hammer drills deliver power and versatility

A hammer drill is a specialized power tool designed to drill holes into hard materials like concrete, masonry, and stone. Unlike a standard drill, a hammer drill combines rotary drilling with a rapid hammering action. This dual-action mechanism allows the drill bit to not only spin but also move back and forth, delivering a pounding force that helps break up tough surfaces. The result is faster, more efficient drilling in materials that would be challenging for regular drills.

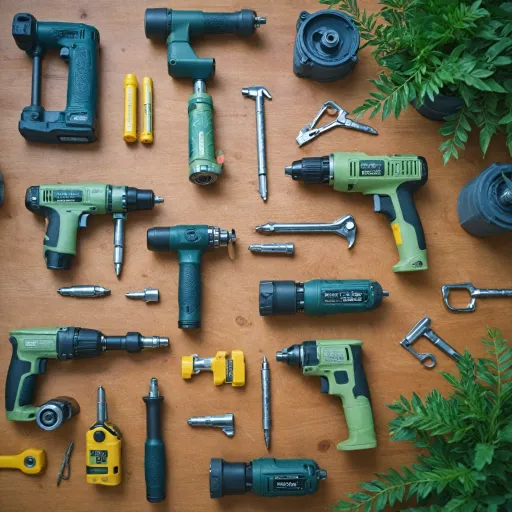

Hammer drills are often included in cordless drill sets, making them a versatile addition for both professionals and DIY enthusiasts. The cordless design offers freedom of movement and convenience, especially when working in areas without easy access to power outlets. Many modern hammer drills use brushless motors, which provide high performance, longer tool life, and improved battery efficiency.

When shopping for a hammer drill, you’ll notice that some models are labeled as rotary drills or rotary hammers. These terms refer to the same basic hammering action, but rotary hammers are typically more heavy duty and suited for larger jobs. Cordless hammer drills can also function as standard drills or drivers, allowing you to switch between drilling holes in wood, driving screws, and tackling masonry projects with a single tool.

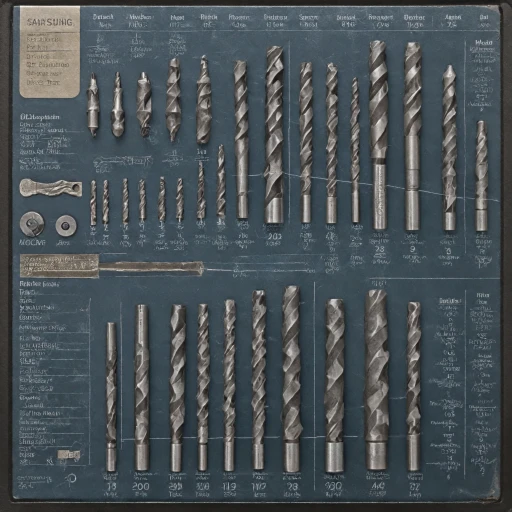

It’s important to use the right drill bit for the material you’re working with. Masonry bits are designed for concrete and brick, while wood bits are better for softer materials. The hammering action of a hammer drill, combined with the correct bit, allows you to drill holes efficiently and with less effort.

For those tackling especially tough jobs, you might want to explore why choose a gasoline-powered drill for tough jobs as an alternative to cordless options. However, for most home and professional uses, a cordless hammer drill offers the right balance of power, portability, and versatility.

Key features to look for in a cordless hammer drill

Essential Qualities for a Reliable Cordless Hammer Drill

When shopping for a cordless hammer drill, it’s important to focus on features that ensure both performance and durability. The right combination of power, versatility, and comfort can make a big difference, especially if you plan to drill holes in concrete, masonry, or other hard materials. Here’s what to look for:

- Power and Voltage: Higher voltage means more drilling impact and the ability to handle heavy duty tasks. Most cordless hammer drills range from 12V to 20V, with 18V and 20V models offering high performance for demanding jobs.

- Hammering Action: The hammering mechanism is what sets these tools apart from standard drills. Look for a rotary drill with a robust hammering action, which allows the drill bit to break through tough materials like masonry and concrete.

- Brushless Motor: Brushless motors are more efficient and durable than brushed ones. They deliver more power, extend battery life, and require less maintenance, making them ideal for frequent drilling and driving screws.

- Variable Speed and Torque Settings: Adjustable speed and torque let you match the tool’s performance to the material—whether you’re drilling holes in wood, metal, or concrete. This flexibility is crucial for both precision and heavy duty work.

- Chuck Size and Compatibility: A 1/2-inch chuck is standard for most cordless hammer drills, accommodating a wide range of drill bits and driver bits. Quick-change chucks make swapping bits easier, saving time on the job.

- Battery Life and Charging: Lithium-ion batteries are preferred for their long run time and quick charging. Consider tools with spare batteries or fast chargers if you plan to use your drill for extended periods.

- Ergonomics and Build Quality: Comfort matters, especially during long drilling sessions. Look for a tool with a balanced design, comfortable grip, and durable construction to withstand jobsite conditions.

- Additional Features: LED work lights, belt clips, and carrying cases can add convenience and safety to your cordless drill set.

For those tackling especially tough jobs, such as drilling into reinforced concrete or other hard materials, it may be worth considering alternative power tools. Why choose a gasoline powered drill for tough jobs explores when a gasoline-powered drill might be the right choice for your shop or worksite.

Choosing the right cordless hammer drill ensures you have a versatile tool that can handle everything from drilling holes in masonry to driving screws into wood. The right features will help you get the most out of your power tools, whether you’re a professional or a DIY enthusiast.

Benefits of using a hammer drill in a cordless drill set

Why a Hammer Drill Adds Value to Your Cordless Drill Set

When you add a hammer drill to your cordless drill set, you’re not just expanding your collection—you’re unlocking a new level of versatility and power. Here’s why this tool stands out among other drills and drivers:- Enhanced Drilling Power: The hammering action lets you drill holes in hard materials like concrete, masonry, and brick, where a standard drill would struggle. This makes it ideal for heavy duty tasks around the shop or jobsite.

- Multi-Material Capability: With the right drill bit, a cordless hammer drill can handle wood, metal, and even tough masonry. This flexibility means you don’t need multiple tools for different materials.

- Efficient Driving and Drilling: The impact and rotary action of a hammer drill allows drill users to switch between drilling holes and driving screws, making it a true multi-purpose power tool.

- Portability and Convenience: Cordless hammer drills offer freedom of movement, letting you work in tight spaces or outdoors without worrying about power outlets or tangled cords.

- High Performance with Brushless Motors: Many modern hammer drills feature brushless motors, which deliver more power, longer runtime, and less maintenance. If you’re curious about the difference between brushless and non-brushless drills, check out this guide to brushless vs non-brushless drills.

Common uses for a cordless hammer drill

Where a Cordless Hammer Drill Excels in Everyday Projects

When it comes to tackling tough jobs around the home or on the job site, a cordless hammer drill stands out for its versatility and power. This tool combines the rotary action of a standard drill with a hammering action, allowing it to drill holes in hard materials like masonry, brick, and concrete. The addition of hammering action means you can take on projects that would be too demanding for a regular drill or even some impact drivers.

- Drilling into Masonry and Concrete: The hammer drill is designed for drilling holes in tough materials. Whether you need to install anchors in concrete walls or run wiring through brick, the hammering action makes the job much easier and faster.

- Driving Screws into Hard Materials: With the right drill bit, a cordless hammer drill can drive screws into dense surfaces where a standard drill or driver would struggle. This is especially useful for mounting heavy-duty fixtures or assembling outdoor structures.

- Versatile Use Across Materials: While hammer drills excel in masonry, they can also be used for wood and metal by simply switching off the hammer function. This allows the drill to act as a standard drill or driver, making it a flexible addition to any power tools collection.

- Heavy Duty and High Performance Tasks: For jobs that require more power, such as drilling large holes or working with thick materials, a brushless cordless hammer drill delivers the torque and endurance needed for professional results.

Many shops and professionals rely on cordless hammer drills for their ability to fill multiple roles, from rotary drilling to impact driving. The cordless design allows drill users to work in tight spaces or remote locations without worrying about power outlets. Whether you’re a DIY enthusiast or a tradesperson, having a hammer drill in your set of tools means you’re prepared for a wide range of drilling and driving tasks, especially when working with hard materials.

Comparing hammer drills to other types of drills

How Hammer Drills Stand Apart from Other Power Tools

When shopping for a cordless drill set, it's easy to get overwhelmed by the variety of drills and tools available. Hammer drills, standard drills, and impact drivers each have their own strengths, but understanding their differences helps you choose the right tool for the job.- Hammer Drills vs. Standard Drills: The main difference is the hammering action. While a standard drill rotates the drill bit to create holes in wood or metal, a hammer drill adds a rapid, percussive motion. This rotary and hammering action allows the drill to break through hard materials like masonry or concrete. If you need to drill holes in brick or stone, a hammer drill is the better choice. Standard drills are more suited for lighter tasks, such as drilling in wood or driving screws.

- Hammer Drills vs. Impact Drivers: Impact drivers are designed for driving screws and bolts with high torque. They use a different kind of impact mechanism, which delivers rotational force rather than the forward hammering action of a hammer drill. While impact drivers excel at driving long screws into tough materials, they are not ideal for drilling holes in masonry. Hammer drills, on the other hand, are built for drilling into hard materials, thanks to their combined rotary and hammering action.

- Hammer Drills vs. Rotary Drills: Rotary drills, sometimes called rotary hammers, are heavy duty tools used for larger masonry jobs. They offer even more powerful hammering action than standard hammer drills and are typically used for drilling larger holes in concrete. For most home or shop projects, a cordless hammer drill provides enough power and versatility without the bulk of a rotary drill.

Tips for maintaining your cordless hammer drill

Keeping Your Cordless Hammer Drill in Top Shape

Regular care is essential for any power tool, and a cordless hammer drill is no exception. With proper maintenance, your drill will deliver high performance whether you’re drilling holes in concrete, driving screws into wood, or tackling heavy duty masonry tasks. Here are practical steps to help you extend the life of your hammer drill and keep it working efficiently:- Clean After Every Use: Dust, debris, and residue from drilling hard materials like masonry or concrete can clog vents and moving parts. Use a soft brush or compressed air to clear out dust from the drill’s exterior and vents.

- Inspect the Drill Bit and Chuck: Check the drill bit for wear or damage, especially after drilling into tough materials. A worn bit can reduce drilling efficiency and strain the tool. Also, ensure the chuck holds the bit securely and is free from debris.

- Monitor Battery Health: Cordless hammer drills rely on battery power. Charge batteries fully before storage and avoid letting them drain completely. Store batteries in a cool, dry place to preserve their lifespan.

- Lubricate Moving Parts: Some drills, especially those with rotary or hammering action, benefit from occasional lubrication. Refer to your tool’s manual for guidance on lubricating the chuck and gears.

- Check for Loose Screws and Parts: Vibration from hammering action and impact drilling can loosen screws and fasteners. Periodically tighten any visible screws on the drill body and handle.

- Store Properly: Keep your drill and accessories in a protective case or tool shop cabinet. This prevents dust buildup and protects the tool from accidental drops or moisture.

- Use the Right Accessories: Always use drill bits and driver bits suited for the material—wood, concrete, or masonry. Using the wrong bit can damage both the tool and the workpiece.

- Brushless Motor Care: If your hammer drill features a brushless motor, it generally requires less maintenance. Still, keep the tool clean and avoid overloading it during heavy duty drilling.