What makes up a cordless drill set

Key Components Found in a Cordless Drill Set

When you open a cordless drill set, you’ll notice a range of parts and accessories designed for both professional DIY and heavy duty tasks. Understanding these drill parts helps you get the best performance and extend the life of your power tool. Here’s a quick look at what typically makes up a quality cordless drill set:

- Power Drill or Drill Driver: The main tool, often featuring variable speed settings and a comfortable grip for precise drilling and driving.

- Drill Chuck: This part holds the drill bit in place. The chuck’s design affects how securely the bit is held and how quickly you can swap bits for different jobs.

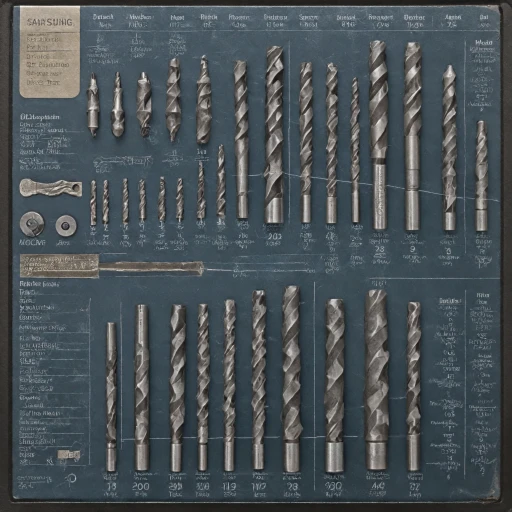

- Drill Bits: Sets usually include a variety of bits, each with a specific shank, cutting edge, and point. You’ll find bits for drilling into metal, wood, and masonry. Some sets even include high speed steel bits, split point bits for cleaner starts, and chisel edge bits for heavy duty cutting.

- Battery and Charger: The power behind your drill. Modern sets offer lithium-ion batteries for longer run times and quick charging, so you can work free from cords.

- Accessories: Many sets include a list of extra parts like bit holders, angle adapters, and even web thinning tools for sharpening or maintaining your drill bits.

Each part plays a role in the overall impact and versatility of your cordless drill set. For example, the shank drill design affects how the bit fits into the chuck, while the cutting edge and point determine the ideal material and speed for drilling. If you want to explore more about the versatility of power tools and their essential accessories, check out this guide on power tool versatility.

As you move through the rest of this article, you’ll learn how each part—from the drill chuck to the battery—contributes to the performance and reliability of your cordless drill set, helping you make informed choices whether you’re working in the United States or elsewhere.

The role of the chuck and how it affects your work

How the Chuck Holds and Releases Drill Bits

The chuck is a key part of any cordless drill set. It’s the component at the front of your power drill that grips the shank of the drill bit. Whether you’re using a heavy duty bit for metal or a high speed bit for wood, the chuck ensures the bit stays secure during drilling. Most modern drill chucks are keyless, allowing you to change bits free of extra tools. This makes it easier and faster to switch between different cutting edges or bit types, which is ideal for professional DIY tasks or quick jobs around the house.

Types of Chucks and Their Impact on Your Work

There are several types of chucks, but the most common in cordless drill sets are the three-jaw and hex chucks. Three-jaw chucks are versatile and can hold a wide range of shank drill sizes, making them suitable for various drill bits, from split point to chisel edge designs. Hex chucks, on the other hand, are best for quick bit changes and are often found in drill drivers and impact drivers. The type of chuck affects how securely the bit is held, the speed at which you can swap bits, and the overall performance of your power tool.

- Three-jaw chuck: Good for round and hex shank bits, offers strong grip for precision drilling.

- Hex chuck: Ideal for quick changes, best for repetitive tasks or when using impact features.

Choosing the Right Chuck for Your Needs

When selecting a cordless drill set, consider what types of projects you’ll tackle. If you often work with different materials like metal or wood, a three-jaw chuck offers flexibility. For tasks requiring frequent bit changes or heavy duty impact, a hex chuck might be more efficient. The chuck’s quality also affects the lifespan of your drill parts and the safety of your work. A worn or loose chuck can cause bits to slip, reducing cutting accuracy and potentially damaging the bit or the workpiece.

For more guidance on selecting the right cordless drill for your needs, check out our detailed guide.

Understanding the motor and its impact on performance

How the Motor Drives Your Drilling Experience

The motor is the heart of any cordless drill set, directly influencing how efficiently you can drill through various materials. Whether you’re working with metal, wood, or masonry, the motor’s design and power output determine the speed, torque, and overall performance of your power drill. Understanding how the motor interacts with other drill parts, such as the chuck and drill bits, helps you get the best results for both professional DIY projects and heavy duty tasks.

- Speed and Torque: Most cordless drills offer variable speed settings. High speed is ideal for drilling small holes, while lower speed with higher torque is better for driving screws or working with tougher materials. The right combination ensures the bit’s cutting edge and point can penetrate efficiently without damaging the shank or the workpiece.

- Brushed vs. Brushless Motors: Brushless motors are more efficient, generate less heat, and often last longer. They’re a top choice for those seeking the best performance and longevity from their power tool.

- Impact on Drill Bits: The motor’s power affects how well your drill bits perform. For example, high speed is essential when using high speed steel bits or when drilling through metal. The motor’s consistency also helps maintain the integrity of the bit’s cutting edge and split point, reducing wear on the chisel edge and shank drill.

Choosing the right motor is crucial for matching your drill to the task. If you’re unsure whether you need a rotary hammer or a rotary drill for your next project, check out this guide to choosing between a rotary hammer and a rotary drill for more details on their differences and ideal uses.

Remember, the motor’s performance is only as good as the other parts in your drill set. The synergy between the drill chuck, bits, and battery ensures you get the most out of your tool drill, whether you’re in the United States or elsewhere. Always consider the full list of drill parts and their compatibility to achieve the best results and extend the life of your cordless drill set.

Battery and charger: the power behind the drill

How Battery Power Shapes Your Drilling Experience

A cordless drill set relies on its battery and charger for consistent performance. The battery is the heart of your power tool, directly influencing the speed, torque, and runtime of your drill driver. Understanding how these parts work together helps you get the best results, whether you’re drilling into metal or wood, or using heavy duty drill bits.- Battery Type: Most modern cordless drills use lithium-ion batteries. They are lighter, charge faster, and hold their charge longer compared to older nickel-cadmium options. This means more free movement and less downtime on your projects.

- Voltage and Capacity: Higher voltage batteries (like 18V or 20V) deliver more power, making them ideal for tough drilling jobs or when using large bits with a thick shank. Capacity, measured in amp-hours (Ah), determines how long you can use your drill before needing a recharge.

- Charger Efficiency: A quality charger is essential for maintaining battery health. Fast chargers can reduce waiting time, but always check if your battery is compatible to avoid damaging the parts.

Common drill bits and their uses

Types of Drill Bits and Their Key Features

When you open your cordless drill set, you’ll notice a range of drill bits, each designed for specific tasks. The right bit can make a big difference in drilling speed, accuracy, and the quality of your work. Here’s a quick guide to the most common types and what makes them essential parts of your power tool kit:- Twist Drill Bits: These are the most common bits, ideal for drilling into wood, plastic, and metal. Their spiral flutes help remove debris, and the split point design reduces wandering when starting a hole.

- Brad Point Bits: Best for wood, these bits feature a sharp point and spurs that create clean holes with minimal splintering. The cutting edge and chisel edge work together for precise results.

- Masonry Bits: Designed for drilling into brick, stone, or concrete, these bits have a reinforced cutting edge and a slightly wider angle. They’re heavy duty and often used with impact settings on your drill driver.

- Spade Bits: Great for making large holes in wood, spade bits have a flat, paddle-like shape. Their wide cutting edge allows for fast drilling, though they’re not suitable for metal.

- Step Bits: These are perfect for drilling holes of various sizes in thin materials like sheet metal. The stepped design lets you drill multiple hole sizes with one bit.

Understanding Bit Anatomy: Shank, Point, and Cutting Edge

Each drill bit has three main parts: the shank, the point, and the cutting edge. The shank is the part that fits into your drill chuck. Most cordless drills use a round or hex shank for a secure grip, reducing slippage during high speed drilling. The point and cutting edge are where the action happens. A split point helps start holes accurately, while a sharp cutting edge ensures efficient material removal.Choosing the Right Bit for the Job

Selecting the best bit depends on your material and the type of hole you need. For metal, high speed steel bits with web thinning are ideal, as they resist heat and wear. For wood, brad point or spade bits offer clean results. Always match the bit to your power drill’s capabilities and the chuck size. Using the wrong bit can damage both your drill parts and your workpiece.Quick Tips for Professional DIY Results

- Keep your bits sharp for clean, fast drilling.

- Use the correct speed setting on your drill driver for each material.

- Check the shank for wear to ensure a secure fit in the drill chuck.

- Store bits free from moisture to prevent rust and maintain cutting performance.

Maintenance tips for long-lasting drill parts

Keeping Your Cordless Drill Set in Top Shape

Regular maintenance is key to getting the best performance and longevity from your cordless drill set. Whether you use your drill for professional DIY projects or occasional home repairs, a few simple habits can help keep every part—from the drill chuck to the cutting edge of your bits—working smoothly.- Clean After Each Use: Dust, debris, and metal shavings can build up around the chuck, drill bits, and vents. Wipe down your power drill with a dry cloth and use compressed air to clear tight spaces. This prevents buildup that can impact speed and power.

- Inspect Drill Bits: Check the cutting edge, point, and shank for wear or damage. Dull or chipped bits make drilling harder and can damage your drill parts. Replace bits that show signs of heavy duty use, especially if the split point or chisel edge is worn down.

- Lubricate Moving Parts: Apply a drop of machine oil to the drill chuck and any moving parts. This reduces friction and helps the chuck grip the shank drill securely, which is ideal for precise drilling in metal or wood.

- Check the Battery and Charger: Make sure your battery is free from corrosion and fully charged before storage. Avoid leaving the battery on the charger for extended periods, as this can reduce its lifespan. Store batteries in a cool, dry place to maintain power and performance.

- Store Properly: Keep your cordless drill set in its case or a dry toolbox. Organize drill bits by type—such as high speed, web thinning, or heavy duty—to make it easy to find the ideal bit for your next project. Protecting the shank and cutting edge from knocks will extend their life.

- Sharpen Drill Bits: For the best results, sharpen bits regularly, especially those used for drilling metal. A sharp cutting edge and correct angle help maintain drilling efficiency and reduce strain on your power tool.