What sets drills and drivers apart

How drills and drivers function differently

When you shop for a cordless drill set, you’ll notice two main tools: the drill and the driver. While they may look similar, their functions and internal mechanisms set them apart. Understanding these differences is crucial for choosing the right tool for your work.

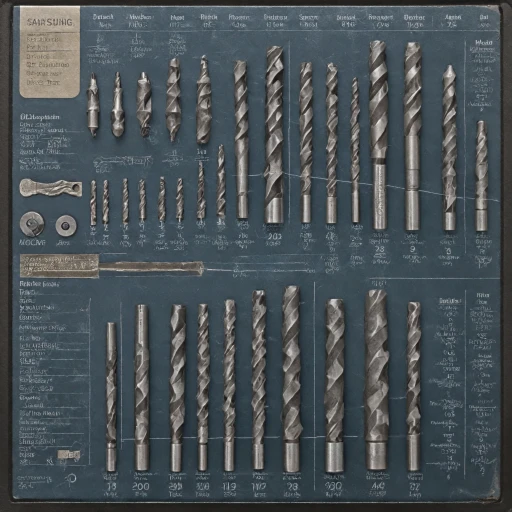

- Drills are designed primarily for drilling holes into materials like wood, metal, or plastic. They use a rotating motion and rely on drill bits to create clean holes. A regular drill offers variable speed and moderate torque, making it versatile for both drilling and light driving screws.

- Drivers, especially impact drivers, are optimized for driving screws and other fasteners. They deliver higher rotational force and impact action, which helps drive screws into tough materials without stripping the screw head. Impact drivers use short bursts of force, or "impacts," to provide higher torque than a standard drill.

Some cordless drill sets include a driver drill—a hybrid tool that can handle both drilling and driving tasks, but with certain limitations compared to dedicated tools. For heavy-duty jobs, a hammer drill or hammer drills add a pounding action to the rotation, making them suitable for masonry and concrete. If you want to learn more about the differences between hammer drills and rotary drills, check out this in-depth guide on hammer drills versus rotary drills.

In summary, drills excel at drilling holes, while drivers—especially impact drivers—are built for driving screws and fasteners with higher torque and force. Knowing these distinctions helps you select the right tool for your next project and avoid common mistakes when building your cordless drill set.

When to use a drill versus a driver

Choosing the Right Tool for the Task

Understanding when to use a drill versus a driver is essential for anyone looking to get the most out of their cordless drill set. Both tools may look similar, but their functions are quite distinct, and using the right one can make your work much more efficient.

- Drills are primarily designed for drilling holes. They use rotational force to spin drill bits through materials like wood, metal, or plastic. If your main goal is to create clean, precise holes, a regular drill or even a hammer drill (for tougher materials) is the right choice.

- Drivers, on the other hand, are optimized for driving screws and other fasteners. They deliver higher torque and often use an impact mechanism to help drive screws into dense materials without stripping the screw head. Impact drivers are especially useful for repetitive driving tasks or when working with longer screws.

For most home projects, you’ll find yourself switching between drilling and driving. Some driver drills combine both functions, but dedicated tools often perform better for their specific tasks. For example, using a power drill to drive screws can sometimes lead to cam-out or damage to the fastener, while a driver with the right driver bits applies the necessary force more efficiently.

When you’re working with harder materials or need to drive screws into dense wood, an impact driver or a drill impact tool provides higher torque and makes the job easier. For more delicate work, like assembling furniture or working with soft woods, a regular drill with adjustable torque settings is usually sufficient.

It’s also important to match the bit to the job. Drill bits are designed for drilling holes, while driver bits are made for driving screws. Using the correct bit helps prevent damage to both the tool and the fastener.

If you want to explore more about the flexibility of hand tools in your cordless drill set, check out this guide on understanding the versatility of a hand drill.

Key features to look for in cordless drills and drivers

Essential Specifications for Cordless Drills and Drivers

When you shop for a cordless drill set, understanding the key features of drills and drivers can make a real difference in your work. The right combination of power, control, and versatility will help you tackle everything from drilling holes to driving screws into tough materials. Here’s what to look for when comparing these essential tools:

- Torque and Rotational Force: Torque is the force that allows a drill or driver to turn a screw or drill bit. Higher torque is especially important for driving screws into dense materials or when using an impact driver for heavy-duty fasteners. Adjustable torque settings on a driver drill help prevent stripping the screw head or damaging your work surface.

- Speed and Power Settings: Most cordless drills and drivers offer variable speed controls. Lower speeds are ideal for driving screws, while higher speeds are better for drilling holes. Some models include multiple gear settings for even more control.

- Impact Mechanism: Impact drivers and hammer drills use a special mechanism to deliver extra force. Impact drivers provide higher torque and quick bursts of rotational force, making them excellent for driving long screws and bolts. Hammer drills add a pounding action for drilling into masonry or concrete. If you want to understand more about battery power and its effect on impact and drilling performance, check out this guide on why a 36V battery makes a difference in your cordless drill set.

- Chuck Size and Bit Compatibility: The chuck holds the drill bits or driver bits. A larger chuck (like 1/2 inch) allows you to use a wider range of bits, which is useful for both drilling and driving tasks. Quick-change chucks on impact drivers make swapping bits fast and easy.

- Battery Life and Charging: Look for tools with lithium-ion batteries for longer run times and less weight. Higher voltage batteries, such as 18V or 36V, deliver more power for demanding jobs. Always consider how long you’ll be working and whether you need a spare battery on hand.

- Ergonomics and Weight: Comfort matters, especially if you’re using your tools for extended periods. Lightweight designs and comfortable grips help reduce fatigue and improve control during drilling and driving.

Choosing the right features in your cordless drill set ensures you have the right tool for every job, whether you’re drilling, driving, or working with tough fasteners. Remember, matching the tool’s capabilities to your specific needs will help you avoid common mistakes and get the most out of your investment.

Common mistakes when choosing between drills and drivers

Overlooking the Importance of Torque and Impact

One of the most common mistakes when choosing between drills and drivers is underestimating the role of torque and impact. A regular drill is designed for drilling holes, but it may struggle with driving screws into tough materials. Impact drivers, on the other hand, deliver higher torque and rotational force, making them ideal for driving screws and fasteners efficiently. Selecting a tool without considering the required torque can lead to stripped screw heads or damaged work surfaces.

Confusing Drill Bits and Driver Bits

Another frequent error is using the wrong bit for the job. Drill bits are meant for drilling holes, while driver bits are specifically designed for driving screws. Using a drill bit in a driver, or vice versa, can result in poor performance and even damage to the bit or tool. Always match the bit to the intended task, whether it’s drilling or driving.

Ignoring the Differences Between Tools

Many shoppers assume that all cordless drills and drivers are interchangeable. However, drivers, drills, and impact drivers each have unique strengths. For example, hammer drills add a percussive force for masonry work, while a driver drill is better for general drilling and driving. Overlooking these differences can limit your set’s versatility and effectiveness.

Underestimating the Need for the Right Accessories

Choosing a cordless drill set without considering the range of included bits and accessories is a common oversight. A versatile set should have various drill bits, driver bits, and possibly even specialty bits for different fasteners. This ensures you’re prepared for both drilling and driving tasks, from simple screws to more demanding jobs requiring higher torque or impact.

Neglecting Tool Maintenance

Finally, failing to maintain your tools and bits can reduce their lifespan and performance. Regularly check for worn or damaged bits, keep your tools clean, and ensure batteries are properly charged. This not only extends the life of your cordless drill set but also ensures safe and efficient operation during drilling and driving tasks.

Tips for maintaining your cordless drill set

Simple habits for a longer-lasting cordless drill set

Keeping your cordless drill set in top shape is easier than you might think. A few regular habits can help your drills, drivers, and impact drivers deliver consistent performance, whether you’re drilling holes or driving screws. Here are some practical tips to help your tools last longer and work better:

- Clean your tools after each use: Dust, debris, and metal shavings can build up around the chuck, vents, and bit holders. Wipe down your drill, driver, and impact driver with a dry cloth. For stubborn debris, use compressed air to clear vents and moving parts.

- Check and replace bits regularly: Dull or damaged drill bits and driver bits make drilling and driving screws harder, requiring more force and risking damage to the screw head or fasteners. Inspect bits for wear and swap them out when needed.

- Store batteries properly: Lithium-ion batteries, common in modern cordless drill sets, last longer when stored in a cool, dry place. Avoid leaving batteries on the charger for days, and don’t let them fully discharge before recharging.

- Lubricate moving parts: A drop of light machine oil on the chuck and other moving parts can reduce friction and help your drill or driver operate smoothly. This is especially important for tools with higher torque or impact functions.

- Use the right tool for the job: Using a regular drill for heavy-duty driving, or an impact driver for delicate drilling, can wear out your tools faster. Match the tool to the task—use impact drivers for driving screws into tough materials and hammer drills for masonry work.

- Monitor torque settings: Adjust the torque to suit the material and fastener. Using higher torque than necessary can strip screws or damage your driver drill.

Quick troubleshooting for common issues

- Loss of power: Check battery charge and connections. If your power drill or driver impact tool feels weak, try a fully charged battery or inspect for corrosion on contacts.

- Bits slipping or wobbling: Ensure the bit is properly seated and the chuck is tightened. For drills impact or hammer drills, use bits designed for those tools.

- Overheating: If your drill or driver gets hot during extended work, let it cool down. Overheating can damage internal components and reduce lifespan.

By following these maintenance steps, you’ll get more reliable performance from your cordless drill set, whether you’re drilling, driving, or tackling projects that require higher torque or impact force. Consistent care means your tools will be ready for any job, from driving screws to drilling holes in a variety of materials.

How to build a versatile cordless drill set

Building a Complete Cordless Drill Set for Every Task

Creating a versatile cordless drill set means thinking beyond just a single drill or driver. The goal is to cover a wide range of drilling and driving jobs, from driving screws into wood to drilling holes in masonry. Here’s how to assemble a set that adapts to your needs:- Choose a reliable power drill: Start with a regular drill that offers variable speed and adjustable torque. This tool handles most drilling holes and basic driving screws into softer materials.

- Add an impact driver: For driving long screws or working with tougher fasteners, an impact driver delivers higher torque and rotational force. It’s especially useful when you need more force than a standard driver drill can provide.

- Consider a hammer drill: If you plan to drill into concrete or masonry, a hammer drill is essential. It combines drilling and hammering action, making it much more effective for these tough materials than a regular drill.

- Stock up on quality drill bits and driver bits: A mix of bits for wood, metal, and masonry ensures you’re ready for any drilling or driving task. Don’t forget specialty bits for unique screws or fasteners.

- Include driver bits for various screw heads: Phillips, flat, Torx, and square bits are common. Having the right bit prevents stripping the screw head and ensures efficient driving.

- Look for tools with adjustable torque settings: This feature helps you control the force applied, reducing the risk of damaging your work or overdriving screws.

- Organize your tools and bits: A sturdy case or organizer keeps your drills, drivers, and bits accessible and protected, making your work more efficient.