Understanding the Basics

Getting Acquainted with the Basics

Before diving into the world of cordless drill sets, it's crucial to have a solid understanding of the essentials. There are various types of drills, each designed for specific tasks, with two main players in the power tool category being the drill driver and the impact driver. Both are indispensable tools but serve distinct purposes, making it vital to understand their functionalities.

A drill driver is designed primarily for drilling holes and driving small screws. It's known for its adaptability and versatility, capable of handling a range of materials such as wood and plastic. This tool typically offers controlled torque settings, allowing for precision driving. On the other hand, the impact driver is celebrated for delivering a higher torque output. This makes it ideal for driving large screws and heavy fasteners into tough materials. The higher rotational speed of an impact driver tackles these demanding tasks efficiently.

Both tools often feature brushed and brushless motors, with brushless options typically providing better efficiency and longevity. As you explore more nuanced details in the subsequent sections, you'll find that brushed motors, while more affordable, may not match the performance and durability of their brushless counterparts.

To gain a comprehensive understanding of which tool best suits your needs, you can explore this guide on choosing the right cordless drill that delves deeper into what each type offers.

Key Differences

Understanding Drill Drivers and Impact Drivers

Deciding on the right tool for your project involves understanding the fundamental differences between a drill driver and an impact driver. Both tools are designed for specific tasks, and knowing these distinctions can make your work more efficient and effective. Drill drivers are versatile power tools popular among DIY enthusiasts and professionals alike. They are primarily used for drilling holes and driving small screws, equipped to handle a variety of materials with ease. The best part about drills is their adjustable torque settings and speed control, allowing users to match the tool's power to the task at hand. Whether you are drilling into wood, metal, or other surfaces, a drill driver provides the precision and controlled strength required for such jobs. On the other hand, impact drivers excel in handling tougher jobs. They are specially designed for driving large screws and fasteners into hard materials. What sets impact drivers apart is their ability to deliver higher torque with more rotational speed, which means driving screws into denser materials becomes significantly more manageable. They work best for construction tasks requiring muscle and speed, and thanks to their compact size, they are effortless to maneuver in tight spaces. While both tools seem similar, their functional differences make them each suited for specific scenarios. If you're still curious about drilling efficiently, consider exploring the versatility of an auger drill attachment as a way to enhance your drilling experience.When to Use a Drill Driver

Optimal Use Cases for Drill Drivers

When it comes to drilling holes and driving screws, a drill driver serves as an excellent versatile tool, ideal for tasks that require precision and control. Unlike impact drivers, which are best suited for high-torque applications, drill drivers offer a balance of speed and power.- Precision Drilling: Drill drivers are designed with adjustable torque settings, allowing users to manage the force applied to the drill bits, a feature particularly useful when dealing with delicate materials or smaller screws. Their ability to adjust power means they are less likely to damage the work surface or strip fasteners.

- Variety of Materials: With brushless motors, these drivers drills work effectively on a range of materials from softwoods to metals. They are equipped to handle diverse projects, from simple household tasks to more complex jobs. They deliver a dependable performance without the noise or vibration often associated with impact drivers.

- Controlled Speed: Many drill drivers offer a variable speed trigger, which allows for controlled adjustments to the rotational speed. This capability ensures better accuracy when securing fasteners and prevents overdriving, which can be a common issue with large screws.

- Light Construction: These power tools typically feature a lighter and ergonomic design, providing comfort during prolonged use. This makes them a preferred choice for continuous tasks such as cabinetry work or assembling furniture, where driving screws efficiently is crucial.

When to Use an Impact Driver

Optimal Situations for an Impact Driver

An impact driver shines in specific scenarios where its unique power features and design offer a distinct advantage over drill drivers. Understanding when to lean on this tool can enhance efficiency and effectiveness in your projects.- High Torque Needs: Impact drivers deliver significantly higher torque compared to their drill counterparts, making them ideal for fasteners requiring substantial power. This includes large screws or lag bolts into dense materials like hardwoods or metals.

- Time-Consuming Tasks: When handling repetitive tasks, such as driving multiple screws into wood, the reduced fatigue and quicker completion time provided by the impact driver’s efficiency make it highly preferable.

- Diverse Projects: For users working across a spectrum of materials, impact drivers can adapt with various drill bits and driver bits, thanks to their 1/4-inch hex chuck, which easily swaps out accessories.

- Situational Use: When facing confined spaces where a conventional drill might struggle, an impact driver's compact size proves beneficial. The rotational speed and power make it efficient in tighter environments.

Factors to Consider When Choosing

Important Considerations for Making the Right Choice

When you're in the market for a cordless drill set, it's crucial to consider several factors before deciding whether to invest in a drill driver or an impact driver. Both tools have their unique features and perform best in different situations. Here are some essential aspects to keep in mind:- Torque and Power: If you're handling projects requiring higher torque and power, such as driving large screws or fasteners into dense materials, an impact driver is likely your best bet. Impact drivers excel in delivering the necessary force with minimal effort.

- Speed and Precision: For tasks that demand more precision and control, such as drilling holes or driving small screws, a drill driver is preferable. With its adjustable speed settings, it allows for greater finesse.

- Type of Motor: Consider whether you prefer a tool with brushed or brushless motors. Brushless motors typically offer higher efficiency and longer lifespan, which is advantageous for heavy-duty usage.

- Versatility: Drill drivers are more versatile for general tasks since they can accommodate a wide range of drill bits. If your work involves frequently switching between drilling and driving, this adaptability can be quite beneficial.

- Weight and Ergonomics: The comfort and ease of handling a power tool are vital, especially for prolonged use. Evaluate the ergonomics, weight, and overall balance of each tool to ensure it meets your needs. Many modern tools are designed with user comfort in mind.

- Budget and Value: Finally, assess your budget against the power tools you're considering. While higher initial investment in a quality tool set can lead to better performance and durability, always weigh this against the expected use and benefits you will gain.

Popular Models and Recommendations

Top Models and Recommendations

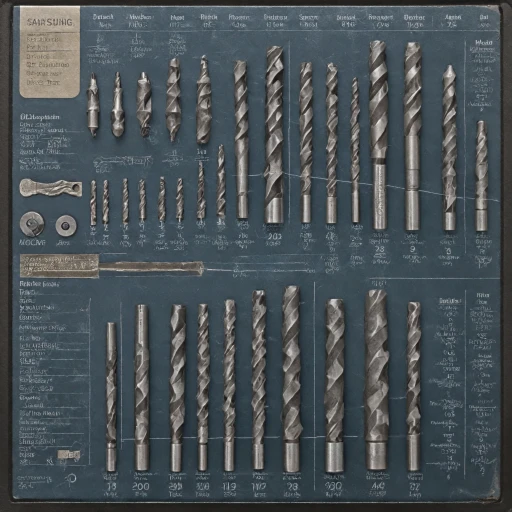

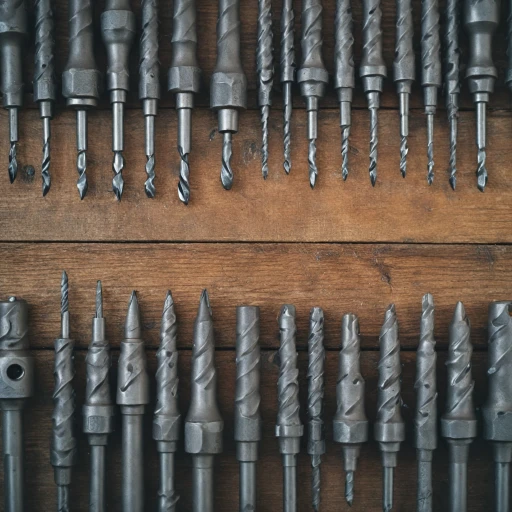

Finding the right power tool can be challenging, so knowing which models are highly recommended can streamline your decision-making process. Here's a look at some popular choices for drill drivers and impact drivers.- Drill Driver Selections: When choosing a drill driver, it's important to consider models that offer versatility across different materials and efficient power management. For those looking for balance, both brushed and brushless motors offer unique advantages. Some top picks include drills with adjustable torque settings capable of handling various drilling jobs and driving screws with precision.

- Impact Driver Favorites: Impact drivers are best suited for tasks involving heavy-duty screws or fasteners. Many professionals and DIY enthusiasts favor impact drivers with brushless motors for their longer lifespan and efficiency. Look for models that provide high rotational speed and higher torque for enhanced driving power.

- Hammer Drill Options: If your work involves drilling holes into tougher materials like concrete, a hammer drill is indispensable. These power tools can effortlessly handle more demanding tasks, providing the right mix of speed and impact necessary for effective drilling.

- Brushless vs. Brushed Motors: The choice between brushed and brushless motors can affect both the performance and lifespan of your tools. Brushless motors are more efficient and require less maintenance, making them a favored option in the long run, especially for frequent users.