The Basics of Hammer Drills and Rotary Drills

Getting to Know Hammer and Rotary Drills

Understanding the key differences between hammer drills and rotary drills is crucial for anyone diving into DIY or professional construction projects. These tools come with their own unique functionalities and are engineered to excel in certain areas.Hammer drills are typically the go-to choice for masonry and concrete veneration. Their primary function is hammering action combined with drilling motion, allowing them to effectively create holes in tough surfaces like concrete masonry. This makes them ideal for those involved in heavy duty tasks that require precision and power.

On the other hand, rotary drills offer a different mechanism. They utilize rotational movement to cut through materials and can often be used for drilling wood, metal, and some lighter masonry tasks. While they might seem similar at the outset, the difference is in their applicability and efficiency when confronted with certain materials.

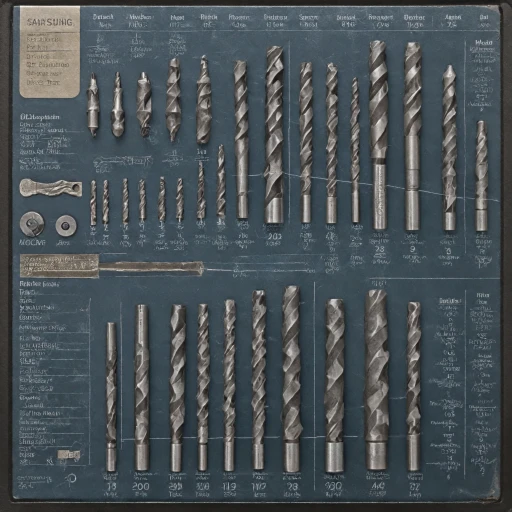

Both tools are equipped with various bits, but only rotary hammers are engineered to accommodate the specialized bits known as SDS. These SDS rotary systems provide superior impact energy, optimizing the tool’s performance when dealing with difficult surfaces. This differentiation becomes pivotal when selecting a tool for a specific task.

Choosing between these drills depends significantly on your project needs. Whether you're drilling into concrete or require a more general-purpose tool, it’s important to weigh their specific characteristics. For more insights on this, you can explore the vast versatility of cordless tools, which might offer alternative approaches or tools like the Milwaukee cordless sds that could serve your purpose better. Understanding these tools can lead to more informed decisions before acquiring equipment for your drilling tasks.

Key Features to Consider in a Cordless Drill Set

Essential Attributes and Considerations for Selecting a Cordless Drill Set

Choosing the right cordless drill set involves understanding various key features that influence performance when tackling specific tasks, whether dealing with masonry or woodworking projects. Here's a look into the crucial attributes one should evaluate.- Power Source: Cordless drills offer a range of battery options, with 18V and 20V being the most common. Opting for a battery-powered model provides the flexibility of portability and ease of use, as opposed to the constraints of corded electric drills.

- Impact Energy: For drilling into concrete or other hard materials, the impact energy, measured in joules or energy lbs, is vital. Specialized tools like rotary hammers or SDS rotary drills provide higher impact energy, making them suitable for heavy duty masonry work.

- Drill Type: Depending on the application, you might choose between hammer drills, rotary hammer drills, or standard drills. Hammer drills and rotary hammers are designed for hammer concrete tasks, while standard drills might suffice for lighter duties.

- Bits and Chuck Type: Ensuring compatibility with the type of drill bits required for your tasks is crucial. SDS max and inch SDS chucks provide a robust mechanism to hold bits securely when drilling holes in concrete masonry.

- Brand Reputation: Brands like Milwaukee Fuel are renowned for their durability and performance in both lightweight and heavy-duty settings. Choosing established brands often ensures reliability and support for accessories like drill bits and adapters.

- Tool Weight and Ergonomics: Consider the drill's weight, particularly with cordless models, as it affects comfort during prolonged use. A balance between tool weight and power output is often ideal, ensuring maximum efficiency without compromising the user's comfort.

When to Use a Hammer Drill

Optimal Scenarios for Choosing a Hammer Drill

When it comes to tackling demanding tasks, especially in masonry, concrete, and other heavy-duty applications, the choice of tool can make all the difference. Hammer drills are your go-to when you need both force and precision for these tough materials. These drills stand out due to their ability to produce rapid hammering action, akin to using a mini jackhammer, making them highly efficient for punching holes through hard surfaces like concrete masonry. For construction professionals and DIY enthusiasts alike, using a hammer drill is ideal when projects involve:- Concrete masonry drilling: The powerful hammering action combined with rotary motion helps drill clean holes with ease.

- Setting anchors: Whether it’s for wall mounts or heavy-duty anchors, a hammer drill ensures the job is completed with precision.

- Driving concrete screws: Benefiting from its high impact energy, the hammer drill allows for fast and secure insertions.

When to Opt for a Rotary Drill

Optimal Scenarios for Using a Rotary Drill

When deciding whether to use a rotary drill, it's important to assess the environment and the nature of the task at hand. Rotary drills are versatile tools, particularly effective when working on materials such as concrete and masonry. Here are some conditions where a rotary drill is your best bet:- Consistent Drilling Needs: If you're engaged in projects requiring frequent and consistent drilling into medium-density materials like concrete or block walls, a rotary drill is ideal. Its construction allows for sustained use without premature wear on the tool.

- Precision and Versatility: For tasks that demand accurate hole placement and depth, the precision of a rotary drill can shine. Equipped with the right drill bits, it can handle both light and heavy-duty drilling tasks effectively.

- Utilizing SDS and SDS Max Bits: The compatibility with SDS and SDS Max bits makes rotary drills highly desirable for masonry tasks. These bits facilitate quick changes, ensuring efficiency when drilling various hole sizes.

- Low-to-Medium Impact Needs: Unlike hammer drills, which are tailored for high-impact energy tasks, rotary drills excel in scenarios with minimal to moderate force requirements. This makes them suitable for a broad range of projects, including installing anchors in concrete.

- Corded vs. Cordless: While corded rotary drills offer continuous power, a cordless rotary drill provides superior mobility and convenience, especially in locations without easy access to electrical outlets. Consider whether your project benefits more from limitless runtime or flexibility.

Comparing Performance and Efficiency

Performance and Efficiency in Action

When comparing the performance and efficiency of hammer drills and rotary drills, several factors come into play. One of the primary considerations is the tool's impact energy, which measures the force delivered during drilling operations. Hammer drills typically provide ample impact energy for tasks like masonry work. Their hammer mechanism allows for efficient drilling into concrete masonry by applying rapid, forceful strikes.

On the other hand, rotary hammers, often deployed in heavy-duty tasks, deliver higher impact energy, making them suitable for more demanding applications. Models such as the SDS rotary hammers use the SDS max bits and inch SDS sizes for increased performance in heavy-duty concrete drilling. This makes them preferred tools for large-scale projects where precision and power are crucial.

Battery technology significantly influences cordless options. Newer cordless rotary and hammer drills feature advanced batteries like the Milwaukee Fuel series, providing extended runtime and consistent power output. Battery operated tools afford the convenience of cordless operation without sacrificing the performance typically expected of corded electric counterparts.

Efficiency is also a factor of the drill bit compatibility. Drill bits designed for specific tasks, such as masonry bits for hammer drilling, enhance the tool's performance. On the flip side, SDS and max rotary bits maximize the rotary hammer's potential, ensuring optimal energy transfer and reduced wear.

The choice between a hammer drill and a rotary drill hinges on the breadth of tasks at hand. For lighter drilling tasks or occasional impact projects, a cordless hammer drill may suffice. In contrast, if the focus is on energy lbs and heavy-duty drilling, a cordless SDS rotary provides the robust performance required.