Understanding Screw Types

Identifying Various Screw Types

When it comes to choosing the right screws for your cordless drill set, familiarity with different types and purposes is crucial. Each screw design is optimized for specific applications, influencing factors like grip, holding power, and ease of installation. Here’s a quick overview to help you get started:- Wood Screws: These are designed with a smooth shank that allows the upper part of the screw to pull two pieces of wood together tightly.

- Machine Screws: Equipped with a uniform, threaded shaft, they're suited for fastening metal parts.

- Countersink Screws: Ideal for applications needing a flush surface, mainly used in woodworking.

- Self-Drilling Screws: Require no pre-drilling, making them time-saving.

- Sheet Metal Screws: Designed for fastening metal sheets, they feature pointed tips for easier penetration.

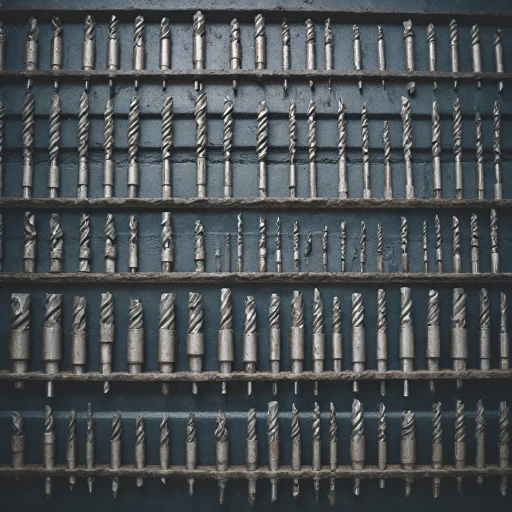

Selecting the Appropriate Drill Bits

Pick the Right Drill Bits for Your Project

When selecting drill bits for your cordless drill set, it's essential to consider not only the size and shape but also the material compatibility. Each drill bit is uniquely designed for specific tasks, so understanding the various types available in your bit set will help streamline your work. Drill bits can be crafted from various materials, each offering unique advantages. High-speed steel (HSS) bits, for example, are versatile for general-purpose drilling in wood, plastic, and soft metals. On the other hand, when you require durability, cobalt drill bits shine with their robustness—ideal for drilling into stainless steel or other hard metals due to their resistance to heat. For woodworking, bradpoint and tapered bits prove highly effective. Bradpoint drills offer precision and clean holes, thanks to their pointed edges. Tapered bits, favored for tasks involving wood screws, match the screw's natural shape, ensuring a tighter fit. Should you need versatility and quick transitions during projects, a set featuring a hex shank might be beneficial. This design allows for efficient bit changes, increasing your productivity. A prominent player in this arena is the Milwaukee Shockwave set, known for its robust performance and quick-change capabilities. While comparing options, consider the implications of black gold or dewalt black coatings. These coatings enhance durability and reduce friction, allowing for smoother drilling. Remember, selecting inappropriate drill bits can lead to poor results or even damage to your tools. Keep this in mind and choose wisely. For a more detailed examination of how to select the right drill bits for your project, you can visit choosing the right drill and drill bits for your cordless set.Compatibility with Cordless Drills

Ensuring Drill Bit and Cordless Drill Set Compatibility

When selecting drill bits, it’s vital to ensure they are compatible with the cordless drill set you own. The first factor to consider is the shank design. For example, a hex shank offers a secure fit in the drill, minimizing slippage during operation. This type of shank is ideal for quick change mechanisms, simplifying the switch between bits.

Next, consider the diameter of the drill bits compared to the drill’s chuck size. Cordless drills typically feature adjustable chucks, accommodating various sizes; however, always verify the manufacturer’s guidelines to avoid compatibility issues. A mismatched drill bit can impact performance, potentially damaging both the bit and the tool.

Additionally, different drills have varying levels of power, affecting their ability to handle different materials. Choosing high-speed steel (HSS drill) bits can offer durability and efficiency, especially for metal drilling, complemented by cobalt drill varieties for even more resilience.

For specific tasks, like those involving delicate or hard materials, such as ceramic tiles, ensuring that your drill's settings support the bit and material is essential. If you're seeking tips on how to manage tile drilling with precision, explore mastering the art of drilling into tile with cordless drills.

Material Considerations

Material Influence on Performance

When selecting drill bits for your projects, material considerations play a crucial role in ensuring efficiency and longevity. The material of the drill bit itself and the material being drilled can significantly impact performance.

High Speed Steel (HSS) drill bits provide a versatile option for various materials, making them a popular choice. While they offer good resistance to heat and durability, HSS drill bits may not be the best choice for hard materials like stainless steel. For tougher jobs, cobalt drill bits offer enhanced heat resistance and performance. These are often used when dealing with stainless steel or other high-density metals.

For those engaging with different types of wood, from soft pine to hard mahogany, bradpoint drill bits are designed to prevent wandering and offer clean, precise holes. Wood screws, too, require specific bits. When working with wood screws, consider using tapered bits, which help reduce splitting and allow for a smooth finish.

Carbon steel is another common material for drill bits, mainly geared for softer materials like wood and plastic. However, these bits don’t offer the durability and heat resistance found in HSS and cobalt variants.

Compatibility Matters

Beyond material, compatibility with your existing cordless drill set is fundamental. Consider hex shank bits, such as the Milwaukee Shockwave bit set, which are designed for quick change and improved gripping strength, reducing slippage and ensuring smoother operation during tasks.

Some projects may require bits suited to a particular purpose, such as countersink bits for creating a tapered entry for screws. When making a decision, comparing the diameter of the bit to the screw shank can help ensure proper selections, preventing mishaps that could compromise the structural integrity of your work.

Maintenance and Care

Prolonging the Life of Your Drill Bits and Screws

Proper maintenance and care of your drill bits and screws can significantly extend their lifespan, ensuring your cordless drill set remains efficient and ready for any task. Here are some tips to help you keep them in top-notch condition.

Regular Inspection and Cleaning

Before and after using your drill bit set, it's crucial to inspect each piece for wear or damage. Check for any signs of rust, worn edges, or broken points, especially on high-use items like HSS drill bits and Milwaukee Shockwave bits. Regularly cleaning your drill bits with a dry cloth to remove any debris will help prevent material build-up, which can affect performance.

Proper Storage

Store your drill bits and screws in a dry place to avoid corrosion. Consider investing in a dedicated storage case or set piece to organize them efficiently. This will not only protect your bits from damage but also make it easier to find specific types like hex shank or bradpoint drill bits when needed.

Use the Right Drill Speed and Pressure

To minimize wear, ensure you're using the correct speed and pressure for the material you're working with. For example, while drilling into harder materials like steel or carbide, use a slower speed to avoid overheating the bit. On the other hand, quicker speeds are suitable when working with softer materials like wood, but excessive pressure should still be avoided.

Lubrication for Metalwork

When drilling into metals, use a lubricant to reduce friction and heat. This is particularly important for high-speed steel and cobalt drill bits. Applying a suitable lubricant will help in maintaining the drill's sharpness and reducing the risk of bit breakage.

Avoid Overheating

Overheating can quickly deteriorate the quality of your drill bits. Give your drill a short rest during prolonged use and avoid letting the bits become too hot. It is essential when working with tapered bits as they are prone to damage when overheated.

Sharpening and Repairs

Regularly sharpen your drill bits using a sharpener or a professional service to maintain their cutting efficiency. If your bits become dull, they won't only be less effective but can also damage the material you're working on. For specialty bits like fuller point or countersink bits, follow the manufacturer's instructions for sharpening or consult a professional.

By incorporating these simple maintenance practices, the life of your drill bits and screws can be prolonged, maximizing the investment in your cordless drill set and ensuring proper performance during all your projects.

Common Mistakes to Avoid

Avoiding Common Pitfalls When Using Your Cordless Drill Set

Picking the right screws and drill bits for your project can sometimes be tricky, and mistakes can happen. Here’s how you can steer clear of some common issues:- Mismatched Screw Types and Drill Bits: Mixing and matching incompatible screws with drill bits can lead to frustrating results. For instance, using wood screws with a high speed steel (HSS) bit might not always be suitable, especially if the material of the screw and the work surface don't align. Always compare the specifications and materials when adding to your bit set or screw collection.

- Incorrect Bit Size: The fuller point and diameter of the drill bit should match the screws or the intended hole size seamlessly. For example, when working with hex shank bits, ensure they fit your drill properly to avoid slippage and enhance precision.

- Neglecting Material Compatibility: As noted earlier, using the wrong bit material, like attempting to use a carbon steel bit on hardened steel, can ruin both the bit and the material. Consider specialized bits such as cobalt drill bits or bradpoint drills for specific tasks.

- Lack of Maintenance: Any drill set, whether it’s Milwaukee Shockwave or Dewalt Black, requires regular maintenance. Neglecting care can lead to dull bits or even a damaged drill. Regularly check the sharpness of your bits, especially tapered bits and countersink bits, and ensure your cordless drills are charged and in optimal shape.

- Overlooking Quick Changes: Many modern drill sets come with quick change features which can save time. However, ignoring this function means you’re not getting the most efficient use out of your tools. Make sure to familiarize yourself with your set piece to fully utilize these features.