The Basics of Masonry Drill Bits

Understanding Masonry Drill Bits

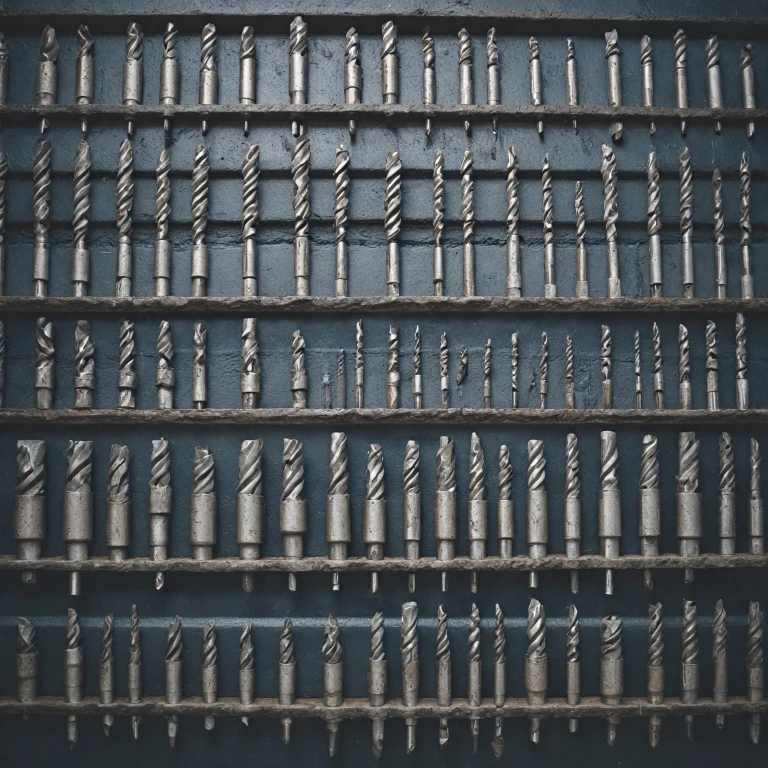

Masonry drill bits play a crucial role in cordless drill sets, especially when tackling tough materials like concrete and brick. These bits are specifically designed to handle the hardness and abrasiveness of masonry surfaces, making them a staple for both professionals and DIY enthusiasts. Masonry drill bits typically feature carbide tips, which are renowned for their durability and heat resistance. This makes them ideal for high-speed drilling into concrete masonry and reinforced concrete, providing efficiency without compromising the integrity of the bit. The carbide bit's ability to withstand intense pressure and friction is what sets it apart from standard bits. Among the various options available, SDS, SDS Max, and spline carbide bits are frequently compared due to their effective drilling capabilities. These types differ mainly in their shank and attachment methods, with SDS Max being preferred for larger bits and more demanding tasks. Hammer drills are often used in conjunction with these bits to maximize their efficacy when drilling concrete. When selecting drill bits, one should compare Milwaukee and DeWalt options, as they are widely recognized for their quality and performance in masonry applications. Whether opting for a bit set or individual pieces, ensuring compatibility with your cordless drill is paramount, as we'll explore later. For further insights on using the right drill bits, you may be interested in learning more about countersink drill bits which also expands the versatility of your cordless drill set. Understanding the distinct roles and features of masonry drill bits will enhance your drilling projects and tool maintenance.Choosing the Right Masonry Drill Bit for Your Cordless Drill

Selecting the Ideal Bit for Your Needs

When choosing a masonry drill bit for your cordless drill, it's essential to compare options to find one that complements your tool and project requirements. Masonry bits are specifically designed for drilling into hard materials like concrete, making them reliable choices for both home and professional use.

The decision begins with understanding the compatibility of the drill bit with your existing drill set. SDS and SDS Max bits are popular for tasks requiring a hammer drill, as their shank design ensures a secure grip and efficient power transfer from the drill to the cutter. Determining the right bit for your drill can enhance your tool's performance significantly.

Material and Design Considerations

When comparing options like Milwaukee and competitors such as those from Dewalt, examine the material and design of the bit. For instance, carbide tipped and high-speed steel bits are highly durable, providing longevity and reliability. This is particularly important when drilling through reinforced concrete or other abrasive materials.

Performance and Speed Factors

Consider the speed and efficiency when drilling with your masonry bit. The design of the drill bit, including its flute and overall build, impacts the speed and cleanliness of your holes. A well-chosen bit will not only breeze through concrete masonry but also extend the life of your drill.

Explore bit sets that offer a variety of sizes and types, allowing you to adapt to different projects. By ensuring your bit is suited to both your drill and material, you pave the way for smoother and more efficient drilling sessions.

Compatibility with Cordless Drill Sets

Evaluating Compatibility with Your Cordless Drill Set

When it comes to integrating masonry drill bits with your cordless drill set, understanding the compatibility factors is crucial. Not all drill bits work seamlessly with every cordless drill, especially when you delve into specialized options such as SDS or rotary hammer drill bits. Here's what you need to consider:- Shank Type and Size: The connection between the drill and the bit is pivotal. Masonry drill bits come in different shank designs like hex shank, spline, and SDS max, which are tailored for specific types of drills. Ensure that your drill supports the shank type of your chosen bit. This compatibility is critical for ensuring efficiency and safety during concrete masonry tasks.

- Drill Power and Speed: Masonry and hammer drills require adequate power and speed to effectively penetrate tough materials like concrete and reinforced concrete. It's important to compare brands like Milwaukee or DeWalt to find a drill that matches the power and speed necessary for your bit's demands. Refer to our guide on choosing the right drill and drill bits for your cordless set for a more detailed discussion on pairing drills and bits effectively.

- Material and Bit Composition: The composition of the bit, such as carbide tipped or high-speed steel, affects its compatibility with different materials. Drilling into concrete requires robust carbide drill bits or carbide cutters. These bits are designed to withstand the intense conditions of concrete drilling while maintaining their integrity.

- Bit Set Variety: A comprehensive bit set that includes various sizes and types will allow you to tackle different projects with versatility. Sets from brands such as Milwaukee offer a range of options that cover different masonry and drilling needs, enhancing the functionality of your cordless drill.

Applications and Projects

Utilizing Masonry Drill Bits for Varied Applications

Masonry drill bits are indispensable tools in construction and DIY projects, offering versatility across a range of applications. When armed with the right cordless drill set, these drill bits allow users to efficiently tackle various tasks involving concrete, stone, and brick. These bits are engineered to withstand the rigors of drilling into hard materials. The advanced design, often featuring carbide-tipped cutting edges, enhances their performance. The heat generated by drilling is managed effectively, maintaining the integrity of the bit over prolonged use. This makes them excellent choices for drilling concrete and reinforced concrete, providing clean, accurate results. For heavy-duty projects, opting for drill bits compatible with hammer drills can significantly enhance your productivity. These specialized bits, including the SDS and SDS Max variants, are optimized for high-impact drilling, essential when working with dense materials. Compare the capabilities of Milwaukee and other leading brands, like DeWalt, to find the optimal set for your needs. When selecting a masonry drill bit set, it's crucial to consider the shank type. Options like the hex shank and spline carbide are designed for specific drills, ensuring a secure fit and efficient power transfer. In addition to industrial applications, masonry drill bits are perfect for home improvement tasks, such as installing anchor bolts or creating drainage holes in concrete planters. Their ability to handle various tasks with precision and ease makes them invaluable in both professional and DIY contexts.Maintenance and Care for Masonry Drill Bits

Ensuring Longevity and Performance

Maintaining your masonry drill bits is crucial to ensure their longevity and optimal performance, especially when dealing with tough materials such as reinforced concrete and bricks. Cleaning your bits after every use is the first step. Gently remove any debris and dust, ensuring not to dull the bits. This is particularly important when working with concrete and other masonry materials where residue can accumulate quickly.

Regularly inspect the drill bits for any wear and tear. Look for signs of dullness or damage, such as warped shanks or broken carbide cutters. When using cartridge-tipped bits, inspect the carbide tips as they are crucial for the effectiveness of the drilling process, especially in high speed applications.

Lubrication is another key factor. Although masonry drill bits used with a hammer drill or rotary hammer may not require as much lubrication as others, a bit of oil can minimize friction and prevent overheating, extending the life of the bit.

Storage also plays a significant role. Storing your drill bits in a dry and safe environment, preferably inside a bit set or case, will protect them from moisture and physical damage. Milwaukee and Dewalt offers excellent options for bit cases that help organize and preserve your bit set.

When it comes to sharpening, for bits such as sds max or spline carbide, professional sharpening is advised. Attempting to sharpen carbide or high speed steel bits without proper tools can result in irreversible damage. Compare the sharpening services from different specialist providers to ensure you're getting value for money.

By following these maintenance strategies, not only will you ensure that your drill bits remain effective, but you'll also save money by reducing the need for frequent replacements and repairs. Keep in mind that drilling concrete with well-maintained tools reduces risks and increases the speed and quality of your work.

Troubleshooting Common Issues

Solving Common Drill Bit Challenges

When working with masonry drill bits, even seasoned DIYers and professionals encounter some challenges. Here are common issues to watch out for and how best to solve them, with a focus on durability and performance when drilling concrete or reinforced materials.- Drill Bit Wearing Out Quickly: This often happens if the bits are not suitable for the material being drilled. Consider using carbide tipped options for concrete masonry, as they are specifically designed for toughness and are durable enough to withstand high-speed use. Furthermore, compare Milwaukee and other reputable brands as they often offer premium options that ensure longevity.

- Incompatibility with Drill : Make sure to match the shank type with your drill. If your drill requires an SDS max or hex shank, ensure your bit set is compatible. Hammer drills, specifically, demand bits with SDS or spline carbide shanks for efficient drilling.

- SDS or Carbide Bits Getting Stuck: Avoid pushing too hard, which can lead to bits binding in the masonry. Maintain an optimal drilling speed, allowing the drill's hammer action to do most of the work. This technique helps prevent overheating, which can damage carbide drills.

- Uneven Holes or Breaking Material: More pressure does not mean faster results. Allow the weight of the hammer drill itself to apply force, and use a lower speed setting on tougher materials. This approach ensures precision without compromising the surrounding material.