Understanding Drill Bit Materials

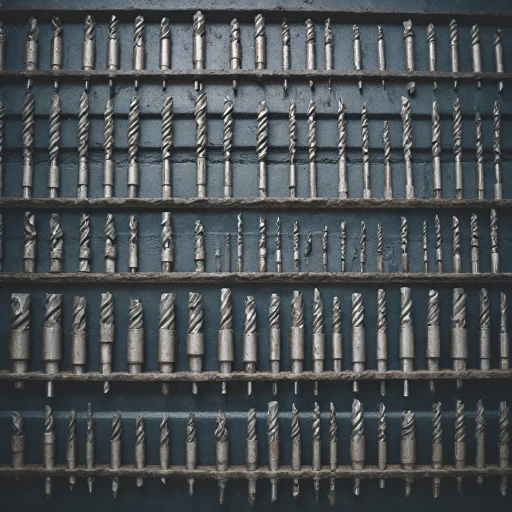

Exploring Drill Bit Materials

When it comes to selecting the right drill bits for your cordless drill set, understanding the materials used in their construction is crucial. The material of a drill bit significantly influences its performance, durability, and suitability for different tasks. Here’s a breakdown of common materials used in drill bits:

- High-Speed Steel (HSS): Known for its versatility, HSS bits are ideal for drilling into wood, metal, and plastic. They offer a good balance of durability and cost-effectiveness, making them a staple in many bit sets.

- Cobalt Steel: These bits are an upgrade from HSS, containing a percentage of cobalt, which enhances their heat resistance. Cobalt drill bits are perfect for drilling into harder materials like stainless steel and other metals.

- Carbide: Solid carbide bits are extremely hard and can maintain a sharp edge longer than other materials. They are excellent for high-speed drilling and are often used in masonry and concrete drilling tasks.

- Tungsten Carbide Tipped: These bits combine the toughness of steel with the hardness of carbide, making them suitable for hammer drills and rotary hammers when working with masonry and concrete.

Each material has its strengths and weaknesses, and the choice largely depends on the specific application and the material you are drilling into. For more detailed insights on the types of drill bits suitable for various tasks, you might want to explore further here.

Types of Drill Bits for Various Tasks

Variety of Drill Bits for Every Drilling Task

When you invest in a drill bit set, it's crucial to understand the different types of bits and their specific applications. The material you're drilling into dictates the type of bit you'll need, ensuring efficiency and accuracy. Here’s a breakdown of commonly used drill bits and their intended tasks:- Twist Drill Bits: These are your go-to bits for general-purpose drilling in materials like wood and metal. Made from high-speed steel, they're highly durable and versatile. For added cutting efficiency, particularly in harder materials, a cobalt drill bit might be necessary.

- Masonry Drill Bits: Perfect for hammer drills, masonry bits are specifically designed to penetrate hard materials. When working with concrete and stone, SDS or SDS max masonry drill bits offer added durability and compatibility with rotary hammers.

- Carbide-Tipped Bits: Ideal for tougher jobs requiring a precise hole. The solid carbide tips can tackle materials like stainless steel and hardened metals. For more extensive tasks, these bits provide longevity and robustness, especially useful in harsh drilling conditions.

- Wood Drill Bits: Tailored for woodworking, these bits have various designs like spade and auger bits, providing a clean cut into wood surfaces. Wood bits typically have a hex shank for quick changes during your project.

Compatibility with Cordless Drills

Pairing Your Cordless Drill with the Right Bits

When it comes to optimizing the performance of your cordless drill set, ensuring compatibility between your drill and the bits you use is paramount. Each bit has unique qualities that contribute to its effectiveness, and matching these correctly with your drill can significantly impact your results.

First and foremost, consider the shank type of your drill bits. Cordless drills commonly accommodate hex shank bits, which ensure a strong grip and reduce slipping during use. These are particularly useful for straightforward drilling tasks like creating holes in wood or metal.

For heavy-duty drilling into tougher materials such as concrete or masonry, a bit set featuring SDS or SDS Max shanks might be more effective. These are specifically designed for use with hammer drills and rotary hammer tools, providing the strength and durability needed to penetrate hard surfaces.

Additionally, the material of your drill bits is crucial. High-speed steel (HSS) bits are versatile for general drilling tasks. However, when drilling into harder materials like stainless steel or concrete, opting for solid carbide or carbide-tipped bits will significantly enhance performance and lifespan.

It is also important to understand the specific requirements of your project. For instance, tasks involving drilling into tile will necessitate a specialized bit designed to prevent chipping and ensure clean cuts.

Before purchasing, always review the specifications of your cordless drill to ensure it can handle the bits you intend to use. This careful alignment between drill and bit will not only enhance the efficiency of your tool but also prolong its life, saving you from unnecessary costs in the future.

Maintaining and Storing Drill Bits

Best Practices for Care and Storage

Taking good care of your drill bits is crucial to keep them in top condition for precise drilling work. Here are some handy tips:

- Keep them clean: After each drilling session, make sure to wipe the bits with a clean cloth to remove dust and debris. For materials like masonry or metal, this reduces wear over time.

- Proper organization: Use a dedicated drill bit set case to store your bits. This prevents them from knocking around and potentially dulling each other.

- Environment control: Store your bits in a dry environment to prevent rust, especially those made from high speed and cobalt steel.

- Inspect for damage: Regularly check your bits for signs of wear or damage, like chipping in carbide tips, and replace them as needed.

Some additional considerations include using the correct type of oil or lubricant specific to the bit material, especially with drill bit sets used on harder surfaces like concrete or masonry.

Safety Tips for Using Drill Bits

Practical Safety Measures

Safety should always be at the forefront of any drilling task, especially when handling a diverse array of drill bits and materials. Here are some key safety guidelines.- Wear Protective Gear: Always wear safety goggles to protect your eyes from flying debris. In scenarios where noise is a factor, such as using a rotary hammer on masonry or concrete, ear protection is advisable.

- Secure Workpiece: Ensure your workpiece is stable. Clamping down materials like wood or metal helps prevent movement, reducing the risk of the bit slipping.

- Select the Right Bit: Using the appropriate bit for your task is crucial. For instance, when drilling through concrete, using a masonry drill bit with a carbide tip increases efficiency and safety.

- Check Drill Compatibility: Not all bits fit every drill set. Double-checking bit shank compatibility with your cordless drill, whether it accommodates hex shank, SDS max, or another type, can prevent accidents.

- Handle with Care: Drill bits, especially high-speed or solid carbide variations, can be sharp and hazardous. Handle them with care to avoid cuts or injuries.

- Avoid Overheating: Applying gentle pressure prevents friction that may overheat bits made from steel, cobalt, or other materials. Overheating can lead to tool damage or even dangerous snapping.

- Assess Environment: Ensure your work area is well-lit and free of trip hazards. If drilling outdoors, be mindful of weather conditions that may impact safety.