Understanding the role of the drill chuck

The Essential Connection Between Drill and Bit

When exploring cordless drill sets, one of the most crucial components to understand is the drill chuck. The chuck acts as the main interface between your drill and the various drill bits or accessories you use. It holds the bit securely in place, ensuring efficient power transfer from the drill’s motor to the workpiece. Whether you’re working with a hand held drill, a drill press, or even stationary machines, the quality and type of chuck can significantly affect your results.

Chucks come in different forms—keyless, keyed, high precision, and even specialized adapters for unique applications. Each type offers distinct advantages depending on the job, the bit shank (like Weldon shank or morse taper), and the level of precision required. For example, a keyless drill chuck is popular for quick bit changes, while a high quality keyed chuck can provide extra grip for heavy-duty tasks.

It’s also important to recognize that the chuck isn’t just about holding drill bits. It’s designed to accommodate a range of tools and accessories, from bit adapters to CNC tools, making your cordless drill set more versatile. The arbor, taper, and chuck unf thread all play a role in compatibility and performance, especially when switching between hand tools and machines.

Choosing the right chuck drill for your cordless drill set can impact everything from the precision of your holes to the lifespan of your tools. For those comparing drill drivers and impact drivers, understanding the role of the chuck is a key part of making an informed choice. For more details on this comparison, check out this guide on choosing between a drill driver and an impact driver.

- Chucks secure drill bits and accessories for various applications

- Quality and type of chuck influence drilling precision and safety

- Compatibility with shank types, adapters, and machines is essential

- Proper chuck selection can enhance both hand and stationary drilling tasks

Types of drill chucks and their uses

Common Chuck Designs and Their Practical Uses

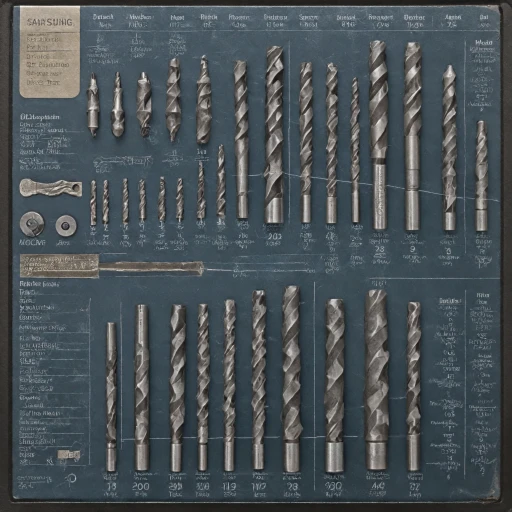

When exploring cordless drill sets, understanding the different types of chucks is essential. The chuck is the part of the drill that holds the drill bit or other tools in place. Its design and mechanism directly affect the range of applications, ease of use, and even the quality of your work. Here’s a breakdown of the most common chuck types and their practical uses:

- Keyed Chucks: These traditional chucks require a key to tighten or loosen the grip on the drill bit. They offer a very secure hold, making them suitable for high-torque applications and precision drill work. Keyed chucks are often found on stationary machines like drill presses and are valued for their reliability, especially when working with larger drill bits or in heavy-duty applications.

- Keyless Chucks: As the name suggests, these chucks can be tightened or loosened by hand, without the need for a separate tool. Keyless drill chucks are popular in cordless drills and cordless screwdrivers due to their quick and convenient bit changes. They are ideal for general-purpose drilling and tasks that require frequent switching between bits.

- Quick-Change Chucks: Designed for speed and efficiency, quick-change chucks or bit adapters allow users to swap out drill bits rapidly. These are especially useful in professional settings or when working with multiple tools and accessories in a single project.

- Precision and High-Quality Chucks: For applications demanding high precision, such as CNC machines or high precision stationary machines, specialized chucks with high quality and high precision ratings are used. These often feature advanced mechanisms to minimize runout and ensure the drill bit remains perfectly centered.

Specialized Chuck Features

Beyond the basic types, chucks can vary by their mounting and compatibility features. For example, some chucks use a morse taper or jacobs taper to fit securely onto the drill’s arbor. Others are designed for specific shank types, such as weldon shank or unf thread, ensuring a tight fit for specialized tools. Chuck adapters are also available, allowing you to use different types of drill bits or accessories with your cordless drill set.

Choosing the Right Chuck for Your Applications

The best chuck for your needs depends on your typical applications, the type of drill bits you use, and the level of precision required. For more on selecting between different drill types, including drill drivers and impact drivers, check out this guide on choosing between a drill driver and an impact driver. Remember, the right chuck not only enhances your cordless drill’s versatility but also contributes to the overall quality and safety of your work.

Compatibility with cordless drill sets

Ensuring Your Drill Chuck Matches Your Cordless Drill Set

When selecting a drill chuck for your cordless drill set, compatibility is crucial for both performance and safety. Not all chucks fit every drill, and using the wrong one can lead to poor results or even damage to your tools. Here’s what you need to know to make the right choice:

- Mounting Systems: Cordless drills typically use either a threaded mount (such as chuck UNF) or a tapered mount (like Jacobs taper or Morse taper). It’s important to match the chuck’s mounting system with your drill’s spindle. For example, a chuck with a Morse taper won’t fit a drill designed for a threaded chuck without an adapter.

- Shank and Adapter Compatibility: The shank size of your drill bits and the arbor of your chuck must be compatible. Some high precision applications or CNC machines require specific shank types, such as Weldon shank or bit adapters, to ensure a secure fit and optimal performance.

- Keyed vs. Keyless Chucks: Many cordless drills now come with keyless drill chucks for quick bit changes, which is convenient for hand held use and cordless screwdrivers. However, for high torque or stationary machines, a keyed chuck may provide better grip and precision.

- Quality and Price: High quality chucks are made from durable materials and offer better concentricity, which is essential for precision drill work. While price can be an indicator of quality, always check if the item is compatible with your specific drill model and intended applications.

For those comparing different cordless drill sets, understanding chuck compatibility is as important as evaluating the drill itself. If you’re interested in how leading brands stack up in this regard, check out this comparison of DeWalt vs Milwaukee cordless drill sets for more insights.

Remember, the right chuck not only fits your drill but also supports the range of drill bits and accessories you plan to use, whether for quick hand jobs or high precision stationary machines.

Changing and securing drill bits

Steps for Swapping and Securing Drill Bits

Changing and securing drill bits is a crucial part of using cordless drill sets efficiently. The process can vary depending on the type of chuck your drill uses, such as keyless, keyed, or quick-change chucks. Here’s a practical guide to help you handle this task with confidence, whether you’re working with hand held drills, stationary machines, or precision drill presses.

- Identify the chuck type: Keyless chucks allow you to change bits by hand, while keyed chucks require a chuck key. Quick-change chucks and adapters make the process even faster, especially for high volume applications.

- Loosen the chuck: For keyless chucks, grip the sleeve and rotate it counterclockwise. For keyed chucks, insert the key and turn until the jaws open. Make sure the jaws are wide enough for the drill bit shank.

- Insert the drill bit: Place the shank of the drill bit or bit adapter into the center of the chuck. For high precision or CNC applications, ensure the bit is seated straight and deep enough for stability.

- Tighten the chuck: For keyless chucks, twist the sleeve clockwise until the jaws grip the bit firmly. For keyed chucks, use the key to tighten at multiple points for even pressure. A secure fit is essential for high quality results and safety.

- Test the grip: Gently pull the drill bit to confirm it’s locked in place. If it moves, retighten the chuck. This is especially important when using high torque cordless screwdrivers or when working with a morse taper or weldon shank bit.

For machines using special chucks, such as those with a jacobs taper or arbor, always check the compatibility of the drill bit and chuck adapter. Some stationary machines and CNC tools require high precision chucks and may use a chuck unf or specific item number for replacement parts. Always follow the manufacturer’s instructions for your drill and chuck to avoid damaging your tools or compromising safety.

Regularly inspect your chucks for wear, debris, or misalignment. A well-maintained chuck ensures high quality performance and extends the life of your cordless drill set. If you notice issues with tightening or holding drill bits, refer to troubleshooting tips or consider replacing the chuck with a high quality model suited to your applications and price range.

Maintenance and troubleshooting tips

Keeping Your Drill Chuck in Top Shape

Regular maintenance of your drill chuck is essential for both hand held and stationary machines. Dust, debris, and metal shavings can build up inside the chuck, especially when switching between different drill bits or using your drill press for various applications. This buildup can affect the grip strength and precision of your chuck, whether it’s a keyless drill or a traditional keyed model.- Clean after use: Wipe the chuck and jaws with a dry cloth after each use. For more stubborn debris, use compressed air or a soft brush. This is especially important for high precision or CNC applications where even small particles can impact performance.

- Lubricate moving parts: Apply a light machine oil to the moving parts of the chuck. This helps prevent rust and ensures smooth operation, particularly for high quality chucks and those with quick change or bit adapter features.

- Check for wear: Inspect the jaws and the shank or arbor connection for signs of wear or damage. A worn jacobs taper or weldon shank can cause the chuck to wobble, reducing accuracy and safety.

Common Issues and How to Fix Them

Even high quality drill chucks can develop issues over time. Here are some troubleshooting tips:- Chuck won’t tighten: If your chuck won’t tighten drill bits securely, check for debris inside the jaws or wear on the threads. For keyless chucks, ensure the mechanism isn’t stripped.

- Bit slips during use: This can be caused by using the wrong size drill bit or a worn chuck. Make sure the bit matches the chuck’s capacity, whether it’s a morse taper, chuck unf, or another standard.

- Difficulty changing bits: For quick change or bit adapter systems, clean and lubricate the moving parts. If the problem persists, the adapter or arbor may need replacement.

Extending the Life of Your Drill Chuck

Investing in a high quality chuck or precision drill accessory can pay off in the long run. Avoid overtightening, especially with hand held cordless screwdrivers, as this can strip threads or damage the jaws. Store your drills and chucks in a dry environment to prevent rust, and periodically check all adapters and tapers for a secure fit. Proper care ensures your tools remain reliable, no matter the price or item specifications.Choosing the right drill chuck for your needs

Key Factors to Consider When Selecting a Drill Chuck

Choosing the right drill chuck for your cordless drill set means balancing several important factors. The right choice will ensure your tools perform efficiently, safely, and with the precision you need for your applications.- Compatibility: Always check the shank size and type of your drill bits, as well as the spindle or arbor of your cordless drill. Some chucks use a morse taper, while others use a jacobs taper or a threaded connection like chuck unf. Using the correct adapter or bit adapter can expand compatibility with different machines and tools.

- Type of Chuck: Keyless drill chucks are popular for quick bit changes, especially in hand held cordless screwdrivers. However, keyed chucks can offer higher gripping force, which is useful for high precision or heavy-duty applications on stationary machines or a drill press.

- Quality and Precision: High quality chucks made from durable materials provide better longevity and accuracy. For CNC or precision drill work, look for high precision chucks with minimal runout. Weldon shank and high precision models are often preferred for specialized tasks.

- Intended Use: Consider what you’ll be drilling. For wood and general DIY, a standard keyless chuck often suffices. For metalworking or CNC, a high precision or quick change chuck may be necessary. If you need to frequently switch between drill bits, a quick change or bit adapter system can save time.

- Price and Value: While price is a factor, investing in a quality chuck can save money in the long run by reducing wear on your drill bits and drills. Compare features, such as tightening mechanisms and included adapters, to ensure you get the best value for your item.

Practical Tips for Making Your Choice

- Test the chuck’s grip by tightening a drill bit and checking for slippage during use.

- Ensure the chuck is easy to operate by hand, especially for cordless machines where quick changes are needed.

- Look for chucks with clear markings for size and taper, which helps when matching with adapters or different drill presses.

- For high torque applications, prioritize chucks with robust construction and secure tightening mechanisms.