Understanding the basics of rotary hammers and rotary drills

What Sets Rotary Hammers and Rotary Drills Apart?

When you’re looking at cordless tools for drilling holes in materials like concrete, masonry, or wood, it’s easy to get confused by the different types available. Rotary hammers and rotary drills may look similar, but their internal mechanisms and intended uses are quite distinct. Understanding these differences is the first step in choosing the right tool for your project.

How Rotary Hammers Work

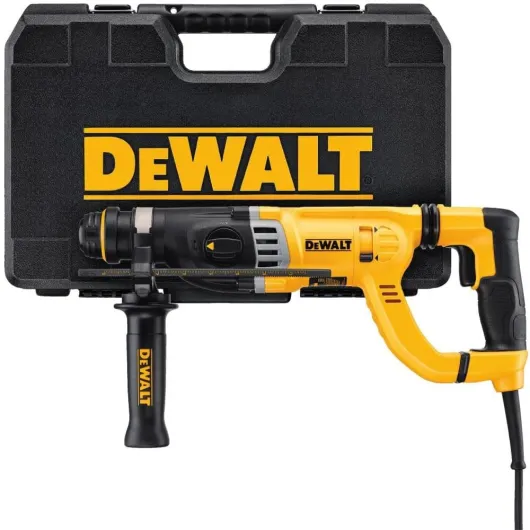

Rotary hammers are designed for heavy duty tasks, especially when it comes to drilling holes in tough materials like concrete and masonry. They use a hammering action combined with rotation, which allows the bit to pulverize material as it drills. This is made possible by a piston mechanism inside the tool, delivering a powerful impact with each stroke. Most rotary hammers use SDS chucks, which securely hold specialized drill bits and allow for quick bit changes. These tools are ideal for jobs that require drilling multiple holes concrete or using larger diameter bits, such as hole saws for pipe installations.

Understanding Rotary Drills and Hammer Drills

Rotary drills, sometimes called regular drills, are more versatile for general drilling tasks. They use a simple rotating motion to drive twist drill bits or other attachments. Many cordless drills can handle light masonry work, but they’re best suited for wood, metal, and plastic. Some models include a hammer drill function, which adds a lighter hammering action compared to rotary hammers. This makes them suitable for occasional drilling in brick or light masonry, but not for heavy duty concrete work.

- Rotary hammers: Best for heavy duty drilling in concrete and masonry, use SDS bits, provide strong hammering action.

- Rotary drills: Great for general drilling and driving tasks, use standard chucks, compatible with a wide range of drill bits.

- Hammer drills: A hybrid tool that offers both drilling and light hammering action, suitable for mixed materials.

Choosing the Right Tool for the Job

Before deciding between a rotary hammer and a rotary drill, consider the materials you’ll be working with and the types of holes you need to make. For drilling holes in concrete or masonry, a rotary hammer is often the best choice. For lighter tasks or more versatility, a cordless drill or hammer drill may be sufficient. Brands like Milwaukee offer a range of cordless tools designed for both heavy duty and everyday use, so it’s important to match the tool to your specific needs.

For a complete guide to cordless battery screwdrivers, you can explore more about the versatility of these tools and how they fit into your toolkit.

Key features to compare in cordless drill sets

What to Look for in a Cordless Drill Set

When comparing cordless drill sets, especially for rotary hammers and rotary drills, it’s important to focus on the features that impact performance, versatility, and durability. The right set can make drilling holes in concrete, masonry, or wood much easier and safer. Here’s a breakdown of the key elements to consider:

- Hammering Action: Rotary hammers and hammer drills offer a hammering mechanism that helps break up tough materials like concrete and masonry. This is essential for heavy duty jobs, while regular drills are better for lighter tasks.

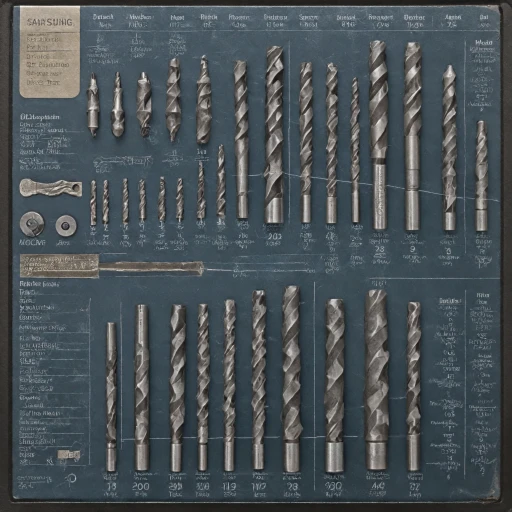

- Chuck Type: The chuck holds your drill bits. SDS chucks are common in rotary hammers, allowing for quick bit changes and better grip during hammering action. Standard chucks are more typical in regular drills and impact drivers.

- Drill Bits Compatibility: Make sure your set includes or supports the right types of bits. For masonry and concrete, SDS bits or carbide-tipped bits are ideal. For wood or metal, twist drill bits and hole saws work well.

- Power and Battery: Cordless tools rely on battery power. Look for lithium-ion batteries with high voltage (like 18V or 36V) for longer runtime and more impact. Milwaukee and other reputable brands often offer interchangeable batteries across their cordless tools.

- Speed and Torque Settings: Adjustable speed and torque let you match the tool’s performance to the material. High torque is crucial for drilling holes in concrete, while lower speeds are better for light masonry or precision work.

- Weight and Ergonomics: A lighter drill is easier to handle, especially when working on an extension ladder or overhead. However, heavier rotary hammers may be necessary for heavy duty drilling holes in concrete.

- Accessories: A complete guide to cordless drill sets should mention included accessories like extra drill bits, a carrying case, and sometimes an impact driver for added versatility.

Comparing Rotary Hammers and Rotary Drills

| Feature | Rotary Hammer | Rotary Drill |

|---|---|---|

| Hammering Action | Powerful, suitable for holes concrete and masonry | Light hammering, best for light masonry |

| Bit Type | SDS, masonry bits | Twist drill, hole saws |

| Best Use | Heavy duty drilling, holes in concrete | General drilling, wood, metal, light masonry |

| Weight | Heavier | Lighter |

| Versatility | Specialized for masonry, concrete | More versatile for different materials |

For more on how cordless tools like screwdrivers can complement your drill set, check out this guide to cordless screwdrivers.

When to use a rotary hammer versus a rotary drill

Best scenarios for rotary hammers

Rotary hammers are the go-to tool when you need to tackle heavy duty jobs, especially in masonry and concrete. Their hammering action and powerful impact make them ideal for drilling holes in tough materials. If you’re working with concrete slabs, stone, or brick, a rotary hammer paired with the right SDS drill bits will save you time and effort. These tools are also excellent for chiseling tasks, such as removing tiles or breaking up old mortar.

- Drilling large diameter holes in concrete or masonry

- Using hole saws or core bits for pipes and wiring

- Demolition tasks with chisel attachments

- Projects requiring repeated hammering action

When a rotary drill is the better choice

Rotary drills, sometimes called regular drills, are more versatile for lighter tasks. They’re perfect for drilling holes in wood, metal, plastics, and light masonry. If you need to drive screws, use twist drill bits, or work in tight spaces, a cordless rotary drill is often more convenient. Many cordless tools now offer hammer drill modes, giving you some masonry capability without the weight of a rotary hammer.

- Drilling pilot holes in wood or metal

- Driving screws with an impact driver attachment

- Working overhead or on an extension ladder

- Light masonry tasks, like drilling into brick for anchors

Choosing the right tool for your project

The decision between a rotary hammer and a rotary drill depends on the material, hole size, and frequency of use. For occasional drilling in light masonry, a hammer drill function on a cordless rotary drill may be enough. But for frequent or large holes in concrete, a rotary hammer is essential. Brands like Milwaukee offer cordless rotary hammers that combine power with portability, making them suitable for both professionals and serious DIYers.

For those looking to maximize flexibility and power, consider reading this complete guide to 36V Li-Ion cordless drill sets to see how modern cordless tools can handle demanding jobs.

Advantages and limitations of cordless rotary hammers and drills

Performance and Power in Cordless Rotary Tools

Cordless rotary hammers and drills have made significant advances in recent years, offering impressive power and flexibility for both professionals and DIY users. The hammering action in rotary hammers is designed for heavy duty tasks, such as drilling holes in concrete or masonry, while cordless drills are more suited for lighter materials and general-purpose drilling. Battery technology, especially in brands like Milwaukee, has improved runtime and impact force, but cordless tools still face some limitations compared to their corded counterparts.Advantages of Cordless Rotary Hammers and Drills

- Portability: Cordless tools are easy to transport, making them ideal for jobs where access to power outlets is limited or when working on an extension ladder.

- Versatility: With the right drill bits, you can switch between drilling holes in wood, metal, light masonry, and even concrete. SDS chucks on rotary hammers allow for quick bit changes and secure bit retention.

- Convenience: No cords to manage means less clutter and faster setup, especially when moving between different work areas.

- Improved Technology: Modern cordless drills and rotary hammers often feature brushless motors, variable speed triggers, and impact driver modes for better control and efficiency.

Limitations to Consider

- Battery Life: Extended drilling in tough materials like holes concrete or heavy masonry can drain batteries quickly. Carrying spare batteries is often necessary for larger projects.

- Power Output: While cordless rotary hammers have closed the gap, corded models still deliver more consistent power for demanding tasks, especially when using large hole saws or drilling deep holes.

- Tool Weight: The battery adds weight, which can be tiring during prolonged use, particularly with larger rotary hammers.

- Bit Compatibility: Some cordless tools have limitations on the types or sizes of drill bits and accessories they can accept, especially compared to full-size corded models.

Choosing the Right Tool for the Job

Selecting between a cordless rotary hammer and a cordless drill depends on the material, the size of the hole, and the frequency of use. For drilling holes in concrete or masonry, a rotary hammer with SDS bits is more efficient and less fatiguing. For general drilling, screwdriving, or light masonry, a regular drill or hammer drill may be sufficient. Understanding the differences in hammering action, chuck types, and available drill bits will help you make an informed choice for your cordless drill set.Tips for maintaining your cordless drill set

Simple habits to extend your cordless drill set’s life

- Clean after each use: Dust and debris from drilling holes in concrete or light masonry can get trapped in the chuck or vents. Wipe down your rotary hammer or drill with a dry cloth and use compressed air for hard-to-reach spots.

- Inspect drill bits and accessories: Dull or damaged drill bits, hole saws, and SDS bits can strain your tool and reduce performance. Regularly check for wear and replace as needed, especially after heavy-duty drilling or hammering action.

- Check the battery: For cordless tools, proper battery care is crucial. Avoid leaving batteries on the charger for extended periods and store them in a cool, dry place. Milwaukee and other reputable brands often provide battery care tips in their manuals.

- Lubricate moving parts: The chuck and other moving components in rotary hammers and hammer drills benefit from occasional lubrication. Use a manufacturer-recommended oil to keep everything running smoothly.

- Store properly: Keep your drills, hammer drills, and bits in a sturdy case. This protects them from moisture and accidental drops, especially if you’re working on an extension ladder or transporting your set between job sites.

Common mistakes to avoid with rotary hammers and drills

- Using the wrong bit type: Always match the bit to the material. For example, use masonry bits for concrete and twist drill bits for wood or metal. Using the wrong bit can damage both the tool and the workpiece.

- Overloading the tool: Forcing a regular drill to handle heavy-duty tasks meant for a rotary hammer can lead to overheating or motor failure. Know the limits of your tools and use the right type for the job.

- Neglecting hammering action settings: Many drills hammer and rotary hammers have adjustable modes. Make sure you’re using the correct setting for drilling, hammering, or both, depending on the material and hole size.

Quick tips for safe and efficient drilling

- Secure your workpiece before drilling holes, especially in masonry or concrete.

- Let the tool do the work—don’t force the bit through the material.

- Use appropriate personal protective equipment, such as safety glasses and gloves, when operating rotary hammers or impact drivers.

| Maintenance Task | Frequency | Tools Involved |

|---|---|---|

| Clean and inspect | After each use | Drills, rotary hammers, bits |

| Lubricate moving parts | Monthly | Chuck, hammering mechanism |

| Check battery health | Monthly | Cordless tools |

| Replace worn drill bits | As needed | Drill bits, SDS bits, hole saws |

Following these tips will help you get the most out of your cordless drill set, whether you’re tackling holes in concrete, light masonry, or using your impact driver for various tasks. Regular care ensures your tools are always ready for the next project.

Frequently asked questions about rotary hammer vs rotary drill

Common Questions About Rotary Hammers and Drills

What is the main difference between a rotary hammer and a rotary drill?Rotary hammers use a hammering action combined with rotation, making them ideal for drilling holes in concrete and masonry. Regular rotary drills, on the other hand, are best for wood, metal, and light masonry. The hammering action in rotary hammers is much more powerful than in standard hammer drills, allowing for heavy duty applications. Can I use the same drill bits for both tools?

No, rotary hammers typically use SDS or SDS-Plus bits, which lock securely into the chuck and withstand the impact. Regular drills and hammer drills use standard twist drill bits or hole saws. Using the correct bit type is essential for safety and performance. Is a cordless rotary hammer as effective as a corded one?

Cordless tools have improved significantly, especially with brands like Milwaukee offering high-performance cordless rotary hammers. For most masonry and concrete tasks, modern cordless hammers deliver enough power and runtime. However, for continuous heavy duty drilling holes in reinforced concrete, corded models may still have an edge. Do I need a hammer drill or a rotary hammer for light masonry?

For light masonry, such as drilling holes in brick or block, a hammer drill is usually sufficient. Rotary hammers are better suited for larger holes or tougher materials like poured concrete. What types of jobs require a rotary hammer?

Rotary hammers excel at drilling holes concrete, chiseling, and demolition work. They are the tool of choice for installing anchors, running conduit, or making large diameter holes in masonry. Can I use a rotary hammer for regular drilling tasks?

While rotary hammers can be used with the hammering action turned off, they are bulkier and less precise than regular drills for woodworking or metalwork. For drilling small holes or using a drill bit in softer materials, a regular drill or impact driver is more suitable. How do I maintain my cordless drill set for longevity?

- Clean dust and debris from the chuck and vents after each use

- Use the right drill bits for each material

- Store batteries properly and avoid extreme temperatures

- Regularly inspect the tool for wear and replace worn parts promptly

- Always wear eye and ear protection

- Secure your workpiece and use an extension ladder safely if working at height

- Let the tool do the work—don’t force the bit

- Check for hidden wires or pipes before drilling holes in walls