Understanding gasoline powered drills

What Makes Gasoline Powered Drills Unique?

Gasoline powered drills stand out in the world of drilling machines for their ability to deliver high performance in demanding environments. Unlike electric or cordless drill sets, these tools use a gas powered motor, often a two-stroke gas engine, to generate the torque and power needed for heavy duty core drilling. This makes them particularly effective for drilling into tough materials like reinforced concrete, where a standard electric drill might struggle.

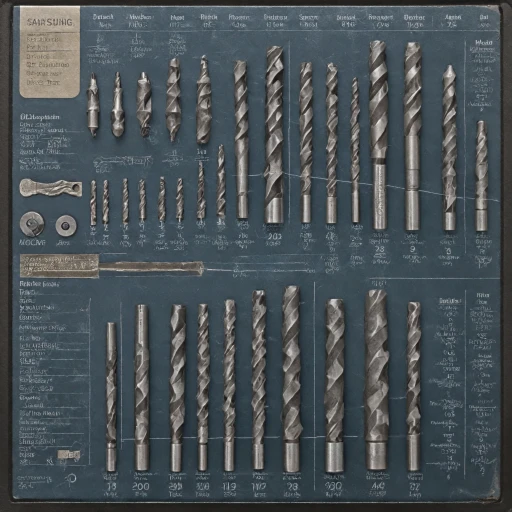

The core of a gasoline powered drill is its robust engine, which allows for greater bit capacity and deeper drilling. Many models feature a safety clutch to protect both the user and the product during operation. A powered core drill can be mounted on a cart for easier maneuverability, especially when working on large construction sites or remote locations where electric power is unavailable. The ability to add a bit extension or swap out the drill bit for different sizes increases the versatility of these machines.

- Gasoline powered drills are often used for core drilling in concrete and masonry.

- They are designed for portability, with many models offering a cart quick view feature for easy transport.

- Heavy duty construction and a safety clutch make them reliable for professional use.

- Bit capacity and stroke gas engine size can vary, so checking product specifications and price is important before adding to cart.

For those interested in exploring alternatives, cordless drill sets and battery powered drills offer different advantages, especially in terms of convenience and portability. To learn more about the versatility of cordless battery screwdrivers and how they compare to gasoline powered options, check out this in-depth guide on cordless battery screwdrivers.

Key advantages of gasoline powered drills

Unmatched Power for Demanding Drilling Tasks

Gasoline powered drills stand out for their ability to deliver high performance in situations where electric or cordless drill sets may fall short. The robust gas powered motor provides consistent torque and speed, making it possible to drill deeper into tough materials like concrete or dense masonry. This is especially important for core drilling, where a powerful motor and a reliable safety clutch are crucial to prevent bit jams and ensure operator safety.

Extended Runtime and Portability

Unlike electric drills that rely on a power outlet or cordless sets that depend on battery life, gasoline powered drills offer extended runtime. With a full tank of gas, users can operate for hours without interruption, making them ideal for remote job sites or locations without easy access to electricity. The addition of a cart quick view or a heavy duty cart allows for easier transport of the drilling machine and accessories, such as bit extension sets and multiple drill bits, directly to the work area.

Versatile Bit Capacity and Application

Gasoline powered core drills are engineered to handle a wide range of bit sizes, often supporting larger inch core drill bits for demanding applications. This versatility means users can switch between different bit capacities for various core drilling needs, from small diameter holes to large openings in reinforced concrete. The clutch system and stroke gas powered design further enhance control and efficiency during operation.

Durability and Heavy Duty Construction

These drills are built for heavy duty use, with reinforced frames and components designed to withstand the rigors of continuous core drilling. The product price often reflects the robust construction and the inclusion of features like a safety clutch, bit extension compatibility, and a reliable powered core system. For professionals who need a drilling machine that can handle repeated use in challenging environments, gasoline powered drills are a solid investment.

For those interested in exploring alternatives for lighter applications or more portable options, you might find value in reading about the versatility of cordless battery screwdrivers.

Comparing gasoline powered drills and cordless drill sets

Performance and Power: Gasoline vs Cordless Drill Sets

When comparing gasoline powered drills to cordless drill sets, the most noticeable difference is the power output. Gasoline powered core drills are designed for heavy duty applications, especially when drilling into tough materials like concrete. Their robust gas engines deliver consistent torque and higher RPMs, making them ideal for core drilling and deep drilling tasks where electric or battery-powered drills may struggle.

- Motor Strength: Gasoline powered drills often feature a high performance stroke gas motor, which can handle larger bit capacities and drill deeper holes with ease.

- Continuous Operation: Unlike cordless drill sets, which rely on battery life, gas powered drills can run as long as there is fuel, making them suitable for extended projects without frequent stops to recharge.

- Bit Extension and Capacity: Gasoline powered core drills support a wide range of bit extensions and larger diameter bits, allowing for more versatile core drilling applications.

Portability and Convenience

Cordless drill sets are known for their portability and ease of use. They are lightweight, compact, and do not require fuel or power cords, making them a popular choice for quick jobs or work in tight spaces. Many cordless drills come with features like a safety clutch, variable speed, and quick view battery indicators. However, when it comes to drilling machine power and bit capacity, they may not match the heavy duty performance of gasoline powered drills.

- Cart and Mobility: Some gasoline powered core drills are mounted on a cart for easier transport, especially when working on large construction sites.

- Electric Alternatives: Electric powered drills offer a middle ground, but may still fall short in terms of raw power compared to gas powered options.

Cost Considerations and Product Selection

Price is another factor to weigh. Gasoline powered drills generally come at a higher initial cost due to their robust build and powerful motor. However, for professionals who need to drill through concrete or require a core drill with a large bit capacity, the investment can be justified by the performance and durability. Cordless drill sets, on the other hand, are more affordable and accessible for general use. For a detailed comparison of top cordless drill sets, including product features and price, check out this guide to choosing between DeWalt and Milwaukee cordless drill sets.

Choosing the Right Tool for the Job

Ultimately, the decision between a gasoline powered drill and a cordless drill set depends on the specific demands of your project. If you require a heavy duty, high performance core drilling machine for concrete or masonry, a gas powered core drill with a safety clutch and large bit extension is likely the best fit. For lighter tasks, portability, and convenience, a cordless drill set offers flexibility and ease of use. Always consider the application, product specifications, and your budget before adding a new drill to your cart.

Common applications for gasoline powered drills

Where Gasoline Powered Drills Excel in Demanding Environments

Gasoline powered drills are engineered for situations where electric or battery-powered drills might struggle. Their robust gas motors and heavy duty construction make them the preferred choice for professionals tackling tough jobs in remote or challenging locations. Here’s a closer look at the most common applications where a gasoline powered core drill or drilling machine truly shines:

- Core Drilling in Concrete and Asphalt: When you need to drill deeper holes in reinforced concrete, asphalt, or masonry, a gasoline powered core drill delivers consistent power and high performance. These drills can handle large diameter core drill bits and bit extensions, making them suitable for demanding construction and roadwork projects.

- Remote Job Sites: On sites without reliable electricity, gas powered drills are indispensable. Their portability and independence from power outlets allow for core drilling and heavy duty drilling tasks in fields, forests, or undeveloped areas.

- Utility and Infrastructure Projects: Gasoline powered core drills are often used for installing pipes, cables, or anchors in infrastructure projects. Their high bit capacity and safety clutch features help manage tough materials and reduce the risk of bit jamming.

- Bridge and Tunnel Construction: The stroke gas motor and robust clutch systems in these drills are designed for continuous use, making them ideal for drilling through thick concrete or rock in bridge and tunnel construction.

- Heavy Duty Industrial Applications: Industries that require frequent, large-diameter core drilling—such as mining, oil and gas, and demolition—benefit from the reliability and power of gasoline powered drills. Their ability to operate with various bit sizes and drilling depths adds versatility to any project.

When selecting a gasoline powered drill, consider the product specifications, such as bit capacity, motor stroke, and safety clutch. Many models come with features like a cart for easier transport, quick view of operational status, and add cart options for accessories. While the price may be higher compared to electric drills, the investment pays off in productivity and durability for core drilling and other demanding tasks.

Safety tips when using gasoline powered drills

Essential Precautions for Safe Operation

When using a gasoline powered drill, safety should always be a top priority. These heavy duty machines, designed for core drilling through concrete and other tough materials, come with powerful motors and features like a safety clutch to protect both the user and the product. However, their high performance and gas powered engines introduce unique risks that require careful handling.- Wear Proper Protective Gear: Always use safety goggles, gloves, and hearing protection. Gasoline powered core drills can generate significant noise and debris, especially when drilling into concrete with a large drill bit or bit extension.

- Check the Area: Before starting, inspect the drilling site for hidden wires, pipes, or other hazards. This is crucial when using a core drill or drilling machine for core drilling in construction environments.

- Secure the Drill and Workpiece: Make sure the drill and the material you are working on are stable. Use a cart or cart quick view system if available, especially for larger powered core drills or when you need to drill deeper.

- Ventilation Matters: Gasoline powered drills emit exhaust. Operate them outdoors or in well-ventilated spaces to avoid inhaling fumes from the stroke gas motor.

- Follow Manufacturer Instructions: Each product may have specific requirements for fuel mix, bit capacity, and clutch settings. Always read the manual before use and adhere to recommended maintenance schedules.

- Use the Right Drill Bit: Match the bit to the material and the drill’s power. Using the wrong bit can damage the drill or cause accidents, especially with high torque gasoline powered drills.

- Monitor for Overheating: Gas powered drills can heat up quickly during heavy duty use. Allow the motor to cool between sessions and never force the drill if it seems to be struggling.

- Keep a Fire Extinguisher Nearby: Since you are working with gasoline, always have a fire extinguisher within reach in case of fuel spills or engine malfunctions.

Maintenance and care for gasoline powered drills

Keeping Your Gasoline Powered Drill in Top Shape

Proper maintenance is essential for any gasoline powered drill, especially when you rely on it for heavy duty core drilling in concrete or other tough materials. A well-maintained drill and motor not only deliver high performance but also extend the lifespan of your investment. Here’s a practical list to help you care for your gas powered core drill:- Regular Cleaning: After each use, remove dust and debris from the drill, bit, and clutch. Pay special attention to the core drill bit and bit extension, as concrete residue can harden and affect drilling efficiency.

- Engine Care: Check the gasoline and oil levels before every job. Use the recommended fuel mix for your stroke gas powered drills. Inspect the air filter and replace it if clogged, as a clean filter ensures the motor runs smoothly.

- Inspect Moving Parts: Examine the safety clutch, drill bit, and cart quick view for wear. Replace worn parts promptly to avoid breakdowns during core drilling.

- Lubrication: Lubricate moving components such as the clutch and bit extension regularly. This reduces friction and prevents premature wear.

- Check Bit Capacity: Always use the correct bit size for your drilling machine. Overloading the drill with an oversized bit can strain the motor and reduce product lifespan.

- Storage: Store your gasoline powered drill in a dry, secure place. If your drill comes with a cart, ensure the cart is stable and the drill is secured to prevent accidental falls.

- Routine Inspection: Schedule periodic checks for the motor, clutch, and core drill. Look for leaks, loose bolts, or unusual noises during operation.