Understanding the difference between corded and cordless drills

How corded and cordless drills differ in use and performance

When you’re deciding between a corded electric drill and a cordless drill set, it’s important to understand how each tool fits different needs. Corded drills, including models from brands like Dewalt, Makita, Bosch, and Black Decker, are known for their consistent power supply. They plug directly into an outlet, which means you get continuous amps and don’t have to worry about battery life. This is especially useful for heavy-duty tasks or longer projects where a power drill needs to run at max speed for extended periods. Cordless drills, on the other hand, offer unmatched portability. They’re battery powered, so you can move freely around your workspace without being tied to an outlet. This makes them ideal for quick jobs, tight spaces, or locations where power access is limited. However, cordless options can sometimes lag behind corded drills in terms of sustained power and torque, especially when dealing with tough materials or using larger drill bits. Here’s a quick comparison to help clarify the main differences:- Power supply: Corded drills rely on direct electricity, while cordless drills use rechargeable batteries.

- Performance: Corded models generally deliver higher, more consistent amps and variable speed, making them suitable for demanding tasks like rotary hammer drilling or using a corded hammer drill.

- Portability: Cordless tools are easier to carry and use in remote areas, but you’ll need to monitor battery charge and sometimes carry spares.

- Price: Corded drills often offer a lower entry price for similar power levels, while cordless sets may cost more due to batteries and chargers included in the drill kit.

Key advantages of electric drills corded

Consistent Power and Performance

Corded electric drills stand out for their ability to deliver steady power throughout any project. Unlike battery powered tools, a corded drill connects directly to a power source, ensuring you get maximum torque and speed without worrying about battery life. This is especially important when using a hammer drill or rotary hammer for tougher materials like concrete or masonry. Brands such as Dewalt, Makita, and Bosch offer corded drills with high amp ratings, often ranging from 6 to 10 amps or more, which translates to more drilling power and efficiency.Cost-Effectiveness and Value

When comparing the price of corded drills to cordless options, corded models are generally more affordable. You don’t have to invest in extra batteries or chargers, which can add up quickly with cordless drill kits. For those who need a reliable tool for occasional or heavy-duty use, a corded electric drill offers solid value. Products from Black Decker and other reputable brands provide a range of options that fit different budgets without sacrificing quality.Versatility for Various Applications

Corded drills are available in many configurations, including corded hammer drills and drill drivers. Whether you need variable speed control for delicate tasks or a pistol grip for better handling, there’s a corded product to match your needs. Many models offer a max speed adjustment and come with a selection of drill bits, making them suitable for wood, metal, and masonry work. If you’re unsure about the differences between a drill and a hammer drill, check out this guide on choosing between a drill and a hammer drill.Long-Term Durability

Corded power tools are often built to last, with fewer moving parts and no batteries to degrade over time. This means less maintenance and a longer lifespan for your investment. Brands like Dewalt, Bosch, and Makita are known for their durable construction and reliable performance, making their corded drills a staple in both professional and home workshops.- Steady power output with no downtime

- Lower upfront and long-term costs

- Wide range of features like variable speed and hammer action

- Trusted brands offer robust, long-lasting products

Common challenges with cordless drill sets

Battery Life and Power Limitations

One of the main challenges with cordless drill sets is their reliance on battery power. While cordless drills offer flexibility and portability, their performance can be limited by battery life and charging times. If you are working on a project that requires continuous drilling or driving, you may find yourself pausing to recharge or swap batteries. This can be frustrating, especially when compared to a corded electric drill, which provides consistent power as long as it is plugged in.

Torque and Speed Consistency

Another issue with many cordless drills is the variability in torque and speed. As the battery drains, the drill may lose power, affecting the efficiency of your work. Corded drills, such as those from brands like Dewalt, Makita, and Bosch, typically offer more stable speed and torque output. This is especially important for demanding tasks that require a lot of force, such as using a hammer drill or rotary hammer on tough materials.

Cost and Long-Term Value

When considering price, cordless drill sets often come at a premium due to the inclusion of batteries and chargers. Over time, you may need to replace batteries, which adds to the overall cost of ownership. In contrast, a corded drill or corded hammer drill can be more affordable and cost-effective in the long run, especially for users who need reliable power tools for frequent use.

Weight and Ergonomics

Cordless drills tend to be heavier than their corded counterparts because of the battery pack. This extra weight can cause fatigue during extended use, particularly with larger drill driver or hammer drill models. Corded drills, especially those with a pistol grip or variable speed (vsr corded) design, are often lighter and easier to handle for long periods.

Accessory Compatibility and Performance

Some cordless drill sets may not deliver enough power for certain accessories, such as large drill bits or attachments for heavy-duty tasks. Corded power drills, with higher amps and consistent output, are better suited for these applications. If you need to use your drill for a wide range of projects, from woodworking to masonry, a corded electric tool may offer better performance and versatility.

For a deeper look at the strengths and weaknesses of cordless options, including how brands like Kobalt are expanding the versatility of their cordless tools, check out this in-depth guide on cordless Kobalt tools.

Features to look for in electric drills corded

Essential Specifications for Choosing a Corded Electric Drill

When selecting a corded electric drill for your next project, it’s important to focus on features that directly impact performance, safety, and value. Corded drills come in a wide range of models, from basic power drills to advanced hammer drills and rotary hammers. Here’s what to look for when comparing products from brands like DeWalt, Makita, Bosch, and Black+Decker:

- Power and Amps: The amp rating is a key indicator of a drill’s power. Most corded drills range from 5 to 10 amps. Higher amps mean more consistent torque and better performance in tough materials. For heavy-duty tasks, consider a drill with at least 7 amps corded.

- Variable Speed Control: A variable speed trigger or dial allows you to adjust the drill’s speed for different materials and applications. This is especially useful for tasks like driving screws or drilling into masonry with a hammer drill.

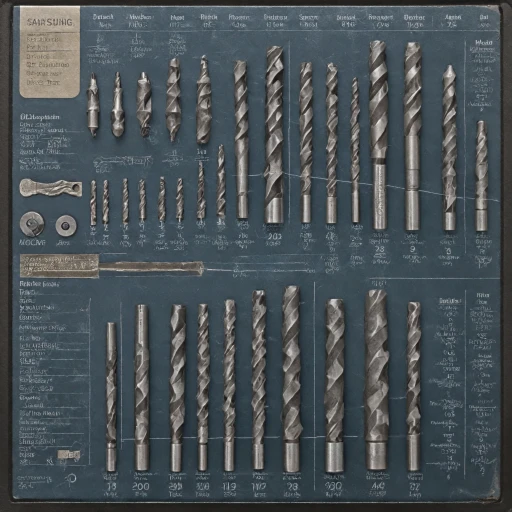

- Chuck Size and Type: The chuck holds the drill bits. Common sizes are 3/8-inch and 1/2-inch. A keyless chuck offers quick bit changes, while a keyed chuck provides extra grip for heavy-duty work.

- Hammer Function: If you plan to drill into concrete or brick, a corded hammer drill or rotary hammer is essential. These tools offer a hammering action that standard drills can’t match.

- Ergonomics and Grip: Look for a pistol grip or side handle for better control and comfort during extended use. A well-balanced tool reduces fatigue and improves accuracy.

- Durability and Build Quality: Metal gear housings and robust switches add to the longevity of the drill. Brands like DeWalt, Bosch, and Makita are known for their durable power tools.

- Price and Value: Compare the price of each product against its features. Sometimes, a drill kit that includes drill bits or a case offers better value than buying tools separately.

Popular Corded Drill Models and Their Features

| Brand | Model | Amps | Max Speed (RPM) | Type | Special Features |

|---|---|---|---|---|---|

| DeWalt | DWD210G | 10 | 1,250 | Drill Driver | VSR Corded, pistol grip, variable speed |

| Bosch | 11255VSR | 8 | 1,300 | Rotary Hammer | Hammer drill function, SDS-plus chuck |

| Makita | HP1641K | 6 | 2,800 | Hammer Drill | Variable speed, dual mode (drill/hammer) |

| Black+Decker | DR260C | 5.5 | 1,500 | Power Drill | Keyless chuck, lightweight design |

When you view different corded drills, always check for features that match your project needs. Whether you need a corded hammer for masonry or a standard drill driver for woodwork, understanding these specifications will help you make a confident, informed choice.

Comparing electric drills corded to cordless options

Performance and Power Output

When comparing corded electric drills to cordless options, the first thing that stands out is power. Corded drills, like the Dewalt or Bosch corded electric models, deliver consistent power measured in amps. With no battery to drain, a corded drill maintains its maximum torque and speed throughout the job. This is especially important for heavy-duty tasks or when using larger drill bits and attachments such as a rotary hammer or hammer drill. Cordless drills, even high-end ones from Makita or Black Decker, can’t always match the sustained performance of a corded power tool, especially as the battery depletes.

Convenience and Portability

On the other hand, cordless drills offer unmatched portability. They’re easy to carry around, especially on job sites without easy access to power outlets. Battery powered drill kits are ideal for quick fixes or work in tight spaces. However, you’ll need to keep spare batteries charged, and the overall weight can increase with higher capacity batteries (max volts or amp hours).

Cost and Value Considerations

Price is another factor. Corded drills are generally more affordable than their cordless counterparts, especially when you consider the ongoing cost of replacement batteries for cordless tools. For example, a corded drill driver with variable speed and pistol grip often offers better value for money if you don’t need the mobility of a cordless drill set. Brands like Dewalt, Bosch, and Black Decker offer a wide range of corded drills at competitive prices, with different amps corded options to suit various needs.

Features and Versatility

Modern corded drills come with features like variable speed, hammer action, and VSR (variable speed reversible) controls. These features make them versatile for drilling into wood, metal, masonry, and more. Corded hammer drills and rotary hammer models are particularly effective for tough materials. Cordless drills have improved, but corded tools still lead in raw power and reliability for demanding tasks.

Summary Table: Corded vs Cordless Drills

| Feature | Corded Drill | Cordless Drill |

|---|---|---|

| Power Output | Consistent, high (measured in amps) | Varies, depends on battery charge |

| Portability | Limited by cord length | Highly portable |

| Price | Generally lower | Usually higher, batteries add cost |

| Runtime | Unlimited (plugged in) | Limited by battery life |

| Best For | Heavy-duty, continuous use | Quick jobs, remote locations |

Choosing between corded and cordless drills depends on your specific needs. If you require maximum power, reliability, and value, a corded electric drill or corded hammer drill is often the better product. For mobility and convenience, cordless drill sets and drill kits offer flexibility, but at a higher price and with some compromise on power and runtime.

Tips for maintaining your electric drills corded

Keeping Your Corded Drill in Top Shape

Proper maintenance is essential to get the most out of your corded electric drill, whether you use a basic drill driver, a heavy-duty hammer drill, or a rotary hammer. Taking care of your tool not only extends its lifespan but also ensures consistent power and safety during every project.- Regular Cleaning: After each use, wipe down your corded drill and remove dust or debris from vents and moving parts. This prevents overheating and keeps the variable speed controls responsive.

- Inspect the Cord: Check the power cord for any signs of wear or damage. A frayed cord can be a safety hazard and reduce the efficiency of your corded power tool. Replace damaged cords immediately.

- Lubricate Moving Parts: For drills with moving chucks or hammer mechanisms, a light application of machine oil can keep everything running smoothly. Refer to the product manual for specific lubrication points.

- Check the Chuck and Drill Bits: Make sure the chuck holds drill bits securely. Clean the chuck regularly and inspect drill bits for dullness or damage. Sharp bits reduce strain on the motor and improve drilling speed.

- Monitor Amps and Power: Using the correct amps corded drill for your tasks prevents motor burnout. For example, a 7-amp or 8-amp corded drill offers more power for heavy-duty jobs, while lower amp models are suitable for lighter tasks.

- Store Properly: Keep your drill kit in a dry place, ideally in a case, to protect it from dust and moisture. This is especially important for brands like Dewalt, Makita, Bosch, and Black Decker, which offer robust cases with their corded drills.

- Follow Manufacturer Guidelines: Always refer to the manual for specific maintenance tips, especially for advanced features like variable speed, pistol grip, or hammer functions.

| Brand | Recommended Maintenance | Typical Amps |

|---|---|---|

| Dewalt | Regular cord inspection, clean vents, lubricate chuck | 6-10 amps |

| Makita | Check variable speed trigger, clean after use | 6-8 amps |

| Bosch | Inspect hammer mechanism, store in case | 7-9 amps |

| Black Decker | Clean drill bits, check corded drill driver function | 5-7 amps |