What sets impact drills apart from hammer drills

Key Features That Distinguish Impact Drills from Hammer Drills

When you’re looking at cordless drill sets, it’s easy to get confused by the terms impact drill and hammer drill. Both are powerful tools, but they serve different purposes and use distinct mechanisms to tackle various materials and tasks. Understanding these differences helps you choose the right tool for your needs, whether you’re driving screws, drilling holes, or working with tough materials like masonry.

- Impact drills (often called impact drivers) are designed primarily for driving screws and bolts. They use a rotary action combined with rapid bursts of high torque, thanks to an internal anvil mechanism. This makes them ideal for driving long screws or bolts into wood, metal, or other dense materials without stripping the bit or the screw head.

- Hammer drills are built for drilling holes in hard materials such as concrete, brick, or stone. They combine rotary motion with a hammering action that pulses the drill bit forward, making them perfect for masonry work. This hammering function is what sets them apart from standard drills and impact drivers.

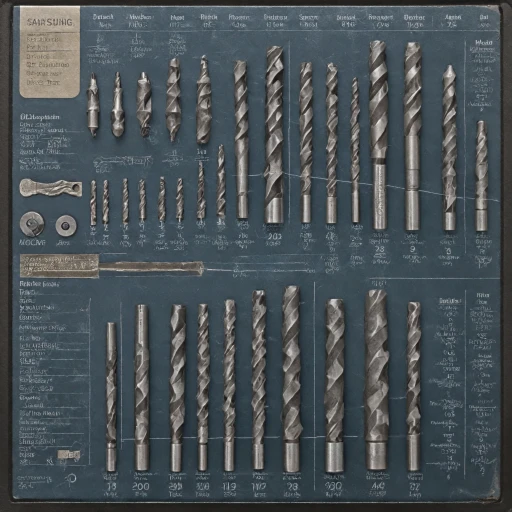

Another key difference is in the type of bits they use. Impact drivers typically accept hex shank bits, which are designed to handle the high torque and sudden impacts. Hammer drills, on the other hand, use standard drill bits suitable for rotary and hammering action, especially when drilling into masonry.

For a deeper dive into how drills and drivers differ in cordless drill sets, check out this guide on the differences between drills and drivers.

As you explore cordless drill sets, keep in mind that each tool’s performance—like torque, speed, and control—will impact your results, especially when working with heavy duty materials or high performance tasks. The right choice depends on the job at hand, the materials you’re working with, and the type of driving or drilling you need to accomplish.

Typical uses for impact drills in cordless sets

Common Scenarios Where Impact Drivers Excel

When you’re working with a cordless drill set, the impact driver stands out for specific tasks that demand more than what a standard drill or driver can offer. Impact drivers are engineered for high torque applications, making them a go-to tool for driving screws and bolts into tough materials like hardwood, metal, or dense composites. The internal anvil mechanism delivers rapid rotary impacts, which helps prevent cam-out and reduces the effort needed to drive fasteners deep and securely.

- Driving long screws: Impact drivers are ideal for deck building, framing, or assembling heavy-duty furniture where long screws are required. The high torque and hammering action help drive screws without stripping the head.

- Fastening into tough materials: Whether you’re working with masonry, thick lumber, or metal, the impact driver’s power and speed make it easier to drive fasteners where a standard drill might struggle.

- Automotive and construction tasks: For tasks like securing lag bolts or working on metal studs, the impact driver’s ability to deliver consistent, high performance is invaluable.

- Quick bit changes: Most impact drivers use a hex shank system, allowing for fast swapping between different driver bits and drill bits, increasing efficiency on the job.

While impact drivers are not typically used for drilling holes in masonry or concrete (that’s where hammer drills shine), they can handle light drilling in wood or metal with the right bit. Their compact design and ergonomic grip also make them comfortable for extended use, especially when working overhead or in tight spaces.

For a deeper dive into how battery-powered drills and drivers fit into modern cordless tool sets, check out this guide to battery-powered drills.

Understanding these typical uses can help you choose the right tool for your next project, ensuring you get the most from your cordless drill set.

When to choose a hammer drill for your projects

Deciding on the Right Drill for Your Project Needs

Choosing between a cordless hammer drill and an impact driver depends on the type of work and materials you plan to tackle. Both tools are essential in a cordless drill set, but their functions and strengths differ significantly.

- Hammer drills are designed for drilling holes into tough materials like masonry, brick, and concrete. Their hammering action helps the drill bit break through hard surfaces, making them ideal for heavy duty masonry work or when you need to drill holes in stone or concrete blocks.

- Impact drivers excel at driving screws and fasteners into wood, metal, or plastic. Thanks to their high torque and anvil mechanism, impact drivers handle long screws and lag bolts with ease, especially in repetitive driving tasks where a standard drill might struggle or strip the screw head.

If your project involves a lot of drilling into concrete or brick, a cordless hammer drill is the clear choice. Its rotary and hammering action delivers the power needed for masonry drilling. On the other hand, for assembling furniture, building decks, or installing drywall, an impact driver offers better control and efficiency for driving screws quickly and securely.

Some cordless drill sets include both tools, allowing you to switch between drilling and driving tasks without changing bits constantly. This is especially useful for high performance jobs where speed and convenience matter. If you often work with a variety of materials, having both a hammer drill and an impact driver in your toolkit ensures you’re prepared for almost any task.

For more guidance on selecting the right accessories, check out this guide to choosing the right drill chuck for your cordless drill set. The right chuck can improve bit compatibility and overall tool performance, especially when switching between drilling and driving applications.

Comparing performance: torque, speed, and control

How Impact and Hammer Drills Perform Under Pressure

When comparing cordless impact drivers and hammer drills, performance comes down to three main factors: torque, speed, and control. Each tool is designed for specific tasks, and understanding these differences can help you choose the right tool for your project.

- Torque: Impact drivers are known for their high torque output, making them ideal for driving screws and bolts into tough materials. The internal anvil mechanism delivers rapid bursts of power, which is especially useful for heavy duty driving tasks. Hammer drills, while powerful, focus their energy on a rotary hammering action, which is better suited for drilling holes in masonry or concrete.

- Speed: Standard drills and drivers typically offer variable speed settings, allowing for more control when drilling or driving. Impact drivers often have higher rotational speed, which helps when driving long screws quickly. Hammer drills, on the other hand, may operate at slightly lower speeds due to the added hammering action, but this is necessary for effective masonry work.

- Control: For precision tasks, such as driving small screws or working with delicate materials, a standard drill or driver may offer better control. Impact drivers can be harder to manage for fine work due to their powerful bursts. Hammer drills require a firm grip, especially when drilling into tough materials, but most cordless hammer drills are designed with ergonomic handles to help reduce fatigue.

Choosing between these tools depends on the job at hand. If you need to drive large screws or bolts into dense wood or metal, an impact driver is your best bet. For drilling holes in brick, stone, or concrete, a hammer drill with the right drill bits will deliver high performance. Many cordless drill sets now include both tools, giving you flexibility for a range of applications.

| Tool Type | Best For | Key Feature | Common Bit Type |

|---|---|---|---|

| Impact Driver | Driving screws, bolts, heavy duty tasks | High torque, hex shank bits | Hex shank driver bits |

| Hammer Drill | Drilling holes in masonry, rotary hammering action | Hammering action, high performance in masonry work | Masonry drill bits |

| Standard Drill | General drilling, light driving | Variable speed, standard drill bits | Twist drill bits |

Ultimately, the right cordless drill set will include the tools and features you need for your specific materials and tasks, whether that's drilling holes in concrete, driving screws into wood, or tackling heavy duty projects.

- + Includes 236 pieces for various tasks

- + Cordless design for easy mobility

- + Comes with a pink bag for storage

- + Great for DIY projects and home repairs

- + Ideal as a gift for special occasions

Battery life and ergonomics in cordless drill sets

How battery life and comfort affect your cordless drilling experience

When you’re working with cordless drills, impact drivers, or hammer drills, battery life and ergonomics can make a big difference in your workflow. The right combination of power and comfort helps you get through tough materials, whether you’re drilling holes in masonry or driving screws into wood. Battery Life- High capacity batteries (measured in amp-hours) let you use your drill or driver for longer periods without stopping to recharge. This is especially important for heavy duty drilling or when using high torque settings.

- Impact drivers and hammer drills often draw more power, especially when drilling into masonry or using the hammering action. Expect faster battery drain with these tools compared to a standard drill driver.

- Some cordless sets come with two batteries, so you can keep working while one charges. This is a practical feature for anyone tackling big projects or working with multiple tools like rotary drills, drivers, and impact drivers.

- Modern lithium-ion batteries hold their charge longer and deliver consistent power, even as the battery drains. This means your drill won’t slow down in the middle of driving screws or drilling holes.

- Comfortable grips and balanced weight distribution reduce fatigue, especially during long drilling or driving sessions. Look for tools with rubberized handles and well-placed controls.

- Compact designs help you work in tight spaces, whether you’re using a drill impact tool or a cordless hammer for masonry work.

- Quick-change chucks, like hex shank systems, make it easier to swap drill bits and driver bits. This saves time and keeps your workflow smooth.

- LED lights and belt clips are small features, but they add convenience when you’re working in low-light or moving between tasks.

Tips for maintaining your cordless impact and hammer drills

Keeping Your Cordless Drills Performing at Their Best

Proper maintenance is essential for getting the most out of your cordless drill set, whether you rely on an impact driver, hammer drill, or a standard drill. With the right care, your tools will deliver high performance and last longer, even when tackling tough materials like masonry or heavy duty drilling jobs.- Clean After Every Use: Dust and debris from drilling holes in wood, masonry, or metal can clog vents and moving parts. Use a dry cloth or compressed air to clean your drill, especially around the chuck, anvil, and hex shank areas.

- Inspect Drill Bits and Drivers: Worn or damaged bits reduce efficiency and can strain your drill’s motor. Regularly check your drill bits, impact drivers, and driver hammer attachments for wear, and replace them as needed for safe, high torque driving and drilling.

- Monitor Battery Health: Cordless hammer drills and impact drivers rely on battery power for speed and torque. Store batteries in a cool, dry place, avoid overcharging, and use the correct charger to maximize battery life and maintain high performance.

- Lubricate Moving Parts: For rotary tools and drills impact mechanisms, a small amount of manufacturer-approved lubricant on the chuck, anvil, or hammering action components can reduce friction and wear, especially after heavy duty or masonry work.

- Check for Loose Screws and Fasteners: Vibration from high speed drilling or hammering action can loosen screws and fasteners on your tools. Periodically tighten all visible screws to keep your drill and drivers safe and stable.

- Store Properly: Keep your cordless drill set in a protective case or tool bag to prevent dust buildup and accidental drops. Organize drill bits, drivers, and accessories so you can quickly find the right tool for drilling holes, driving screws, or working with tough materials.