Understanding the basics of hammer drills and impact drivers

What Makes Hammer Drills and Impact Drivers Unique?

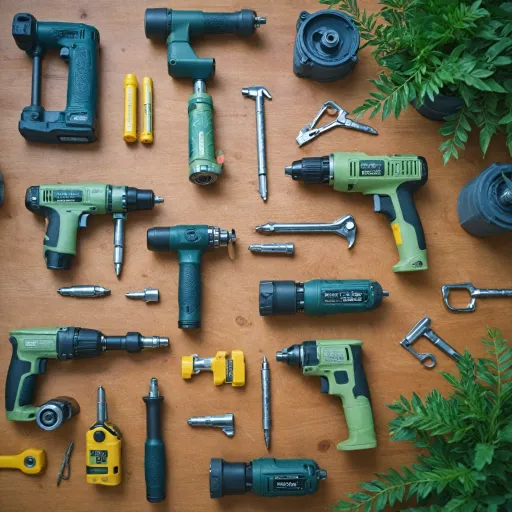

When exploring cordless drill sets, two tools often stand out: the hammer drill and the impact driver. Both are essential for different tasks, but understanding their core functions helps you make the right choice for your projects. Let’s break down what sets them apart and why each tool matters in your toolkit.

- Hammer drills are designed for drilling holes into tough materials like concrete, brick, and masonry. They use a rotary motion combined with a hammering action, which helps the drill bit penetrate hard surfaces efficiently. This makes them ideal for heavy duty jobs and masonry work where standard drills might struggle.

- Impact drivers excel at driving screws and fasteners into wood, metal, or other materials. They deliver high torque through rapid, rotational impacts, making them perfect for driving long screws or bolts without stripping the head. Their compact size and high performance make them a favorite for assembling furniture, building decks, or any task involving lots of screws.

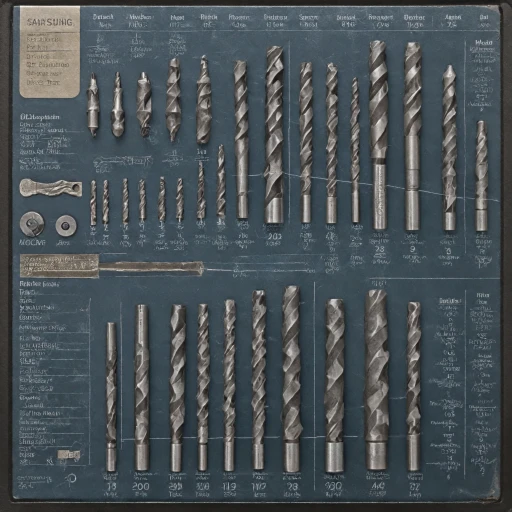

Both tools use different bits: hammer drills typically use round or SDS bits for drilling, while impact drivers use hex shank bits for driving. The cordless versions of these tools add convenience and portability, letting you work anywhere without being tethered to a power outlet.

Choosing between a hammer drill and an impact driver depends on your specific needs. If you’re focused on drilling holes in tough materials, a hammer drill is your go-to. For driving screws quickly and efficiently, an impact driver is the better choice. Many cordless drill sets now include both, giving you versatility for a range of tasks.

For more details on selecting the right driver bits for your cordless drill set, check out this guide on how to choose the right screwdriver T20 for your cordless drill set.

Key differences in design and operation

How Hammer Drills and Impact Drivers Work Differently

When comparing a hammer drill to an impact driver, the first thing to notice is how each tool operates. Hammer drills use a rotary mechanism combined with a hammering action. This means the drill bit not only spins but also moves rapidly back and forth, making it ideal for drilling holes in tough materials like concrete or masonry. The hammering action helps break up the material, allowing the bit to penetrate more easily. Impact drivers, on the other hand, are designed for driving screws and bolts with high torque. Instead of a hammering motion, they use a rotational impact mechanism. This delivers bursts of high torque, making it easier to drive screws into dense materials without stripping the screw head. The impact driver’s hex shank bit system allows for quick changes between bits, which is especially useful when working with different types of screws or fasteners.- Hammer drills: Best for drilling holes in hard surfaces, thanks to their hammering and rotary action.

- Impact drivers: Excel at driving screws and bolts, delivering high torque with less effort from the user.

Design Features and Bit Compatibility

Hammer drills typically use standard drill bits with a cylindrical shank. These are suitable for a wide range of drilling tasks, especially when working with materials like wood, metal, or masonry. Many cordless hammer drills offer variable speed settings, allowing users to adjust the speed for different materials and applications. Impact drivers, in contrast, use hex shank bits. This design is optimized for quick bit changes and high performance when driving screws. The compact size of most impact drivers makes them easier to handle in tight spaces, and their high torque output is ideal for heavy duty driving tasks. If you want to expand your cordless drill set’s capabilities, consider exploring attachments like an auger drill. These can enhance your drilling experience, especially when working with larger holes or specific materials. For more on this, check out this guide on enhancing your drilling experience with an auger drill attachment.Performance and Application Differences

The main difference in performance comes down to the type of work each tool is best suited for. Hammer drills are the go-to choice for masonry work, drilling holes in concrete, and other tasks that require both rotary and hammering action. Impact drivers shine when you need to drive long screws or bolts into tough materials, thanks to their high torque and impact mechanism. Choosing between these tools depends on the materials you’re working with and the type of jobs you tackle most often. Both tools are valuable additions to any cordless tool set, but understanding their unique strengths will help you get the best results for your projects.When to use a hammer drill

Best scenarios for hammer drill use

Hammer drills stand out when you need to tackle tough materials that a standard drill or impact driver can’t handle. Their unique hammering action, which combines rotary motion with rapid impacts, makes them ideal for drilling holes in masonry, concrete, and brick. If your project involves heavy duty tasks like installing anchors in concrete or drilling into stone, a hammer drill is the tool you want in your cordless drill set.

- Masonry work: Hammer drills are designed for high performance in drilling holes into concrete, brick, and stone. The hammering action helps break up hard surfaces, allowing the drill bit to penetrate more efficiently.

- Heavy duty drilling: When you need to make large diameter holes or work with dense materials, the high torque and speed settings of a cordless hammer drill provide the necessary power.

- Versatility with bits: Hammer drills often accept both standard drill bits and masonry bits, giving you flexibility for different tasks. Some models feature a switch to turn off the hammering action, so you can use them as a regular drill for wood or metal.

While hammer drills excel at drilling in tough materials, they are not the best choice for driving screws or working with delicate surfaces. The hammering action can damage softer materials and make precision work difficult. For driving screws or working with wood, an impact driver or standard drill is usually more suitable.

If you’re comparing brands or looking for a high performance cordless hammer drill, you might want to check out this guide on choosing between DeWalt and Milwaukee cordless drill sets for more insights on selecting the right tool for your needs.

When to use an impact driver

Best tasks for an impact driver

When it comes to driving screws quickly and efficiently, the impact driver stands out as the tool of choice. Its high torque output and rapid rotary impacts make it ideal for jobs where standard drills or hammer drills might struggle. If you’re assembling furniture, building a deck, or tackling any project that involves driving a large number of screws, an impact driver will save you time and effort.

- Driving screws: Impact drivers excel at driving screws into wood, metal, and other tough materials. The hammering action helps prevent cam-out, so the bit stays engaged with the screw head, reducing the risk of stripping.

- Working with long or large-diameter screws: The high torque and speed of impact drivers make them perfect for heavy duty tasks like fastening lag bolts or deck screws.

- Driving into tough materials: If you need to drive screws into dense woods or even some masonry work with the right bit, an impact driver’s power and hammering action can handle it.

- Quick bit changes: Most impact drivers use a hex shank chuck, allowing for fast swapping between bits, which is especially useful when alternating between drilling and driving tasks.

While impact drivers are not designed for drilling holes in concrete or masonry like hammer drills, they can handle drilling holes in wood, plastic, and light metals with the appropriate drill bits. For high performance and versatility in driving applications, cordless impact drivers are a reliable addition to any tool kit, especially when paired with a cordless hammer drill for more demanding drilling jobs.

Comparing performance and versatility

Performance in Real-World Scenarios

When comparing hammer drills and impact drivers, it’s essential to look at how each tool performs in practical situations. Both cordless hammer drills and impact drivers are designed for high performance, but their strengths show up differently depending on the task and materials involved.

- Hammer drills excel at drilling holes in tough materials like concrete, brick, and masonry. The hammering action, combined with rotary motion, makes it possible to penetrate hard surfaces that a standard drill cannot handle. If you’re working on masonry work or need to drill holes in concrete, a cordless hammer drill with the right drill bits is the go-to tool.

- Impact drivers are built for driving screws and bolts, especially in heavy duty applications. Their high torque and rapid impact mechanism make them ideal for driving long screws into wood, metal, or composite materials without stripping the screw head. The hex shank design allows for quick bit changes, which is handy when switching between different driver bits.

Versatility and Adaptability

Versatility is another key factor. Hammer drills can often double as standard drills by switching off the hammering action, making them suitable for a range of drilling tasks beyond masonry. However, they tend to be heavier and bulkier, which can be a drawback for overhead work or tight spaces.

Impact drivers, on the other hand, are lighter and more compact, making them easier to handle for extended periods. While they are not designed for drilling holes in concrete or brick, they can handle light drilling tasks in wood or metal with the right bits. Their main advantage is in high speed, high torque driving of screws and fasteners.

| Tool | Best For | Key Strengths | Limitations |

|---|---|---|---|

| Hammer Drill | Drilling holes in concrete, masonry, tough materials | Hammering action, rotary drilling, heavy duty performance | Heavier, less suited for driving screws |

| Impact Driver | Driving screws, bolts, fasteners | High torque, compact size, quick bit changes | Not for masonry drilling, limited drilling capacity |

Ultimately, your choice between a hammer drill and an impact driver will depend on the types of materials you work with and the specific tasks you need to accomplish. Both tools offer high performance, but understanding their strengths and limitations ensures you get the most out of your cordless drill set.

Choosing the right tool for your projects

Matching the Tool to Your Project Needs

When it comes to selecting between a hammer drill and an impact driver, the right choice depends on the specific tasks you plan to tackle. Each tool brings unique strengths to the table, and understanding these can help you avoid frustration and achieve better results.

- Hammer drills excel at drilling holes in tough materials like concrete, brick, and masonry. Their hammering action, combined with rotary motion, makes them ideal for heavy duty drilling jobs where standard drills might struggle. If your projects involve frequent masonry work or require high performance in dense materials, a cordless hammer drill is a smart investment.

- Impact drivers are designed for driving screws and fasteners with high torque. They shine when you need to drive long screws or bolts into wood, metal, or other materials. The impact mechanism delivers bursts of power, reducing the strain on your wrist and preventing stripped screws. For tasks like assembling furniture, building decks, or any job involving lots of driving, impact drivers are the go-to tool.

Consider Versatility and Convenience

If you often switch between drilling holes and driving screws, consider a cordless drill set that includes both a hammer drill and an impact driver. Many sets come with interchangeable drill bits and driver bits, allowing you to handle a wide range of materials and applications. Look for features like variable speed, high torque settings, and a comfortable grip to enhance your control and efficiency.

| Tool | Best For | Key Features |

|---|---|---|

| Hammer Drill | Drilling holes in concrete, masonry, brick | Hammering action, rotary motion, heavy duty, high performance |

| Impact Driver | Driving screws, bolts, fasteners | High torque, hex shank bits, compact design, speed control |

Final Tips for Making Your Choice

- Assess the materials you work with most often. For drilling holes in tough materials, prioritize a hammer drill. For driving screws efficiently, an impact driver is essential.

- Think about the frequency and type of projects you undertake. If you need both drilling and driving capabilities, a cordless set with both tools offers the most versatility.

- Pay attention to battery life, ease of changing drill bits and driver bits, and the overall weight of the tools, especially for extended use.

Choosing the right tool ensures you get the job done efficiently, safely, and with professional results. The right combination of hammer drills and impact drivers can make all the difference in your toolkit.