Understanding the role of a drill socket in cordless drilling

A drill socket is the quiet link between your cordless drill and every stubborn fastener. When matched correctly, a drill socket or full socket drill set transforms a simple driver drill into a compact impact wrench for everyday tasks. This small product choice affects torque drill performance, working comfort, and long term tool safety.

At its core, a drill socket allows a rotating drill shank to transmit torque to a hex or square sleeve that grips the socket. With the right drill adapter or adapter drill, you can connect standard sockets to a driver drill and safely reach high speed without stripping heads. Many users underestimate how much a well designed socket driver or socket drill kit can reduce fatigue and protect the impact drill gearbox.

Modern cordless tools blur the line between hand power and power tools, especially when an impact rated drill socket is paired with an impact drill or compact impact wrench. A good socket driver set lets you move from wood screws to automotive nuts with a simple quick change adapter. For people comparing price and performance, the grade of steel, the quality products finish, and the precision of the shank interface matter more than flashy brand labels.

Professionals also think about inventory management when they select socket drill accessories for a workshop. Clear size markings, consistent extension lengths, and compatible reduction adapters make orders shipped easier to track and replace. Whether you shop products online or in store, understanding how a drill socket works is the first step toward safer, more efficient fastening.

Key components of a drill socket set and how they interact

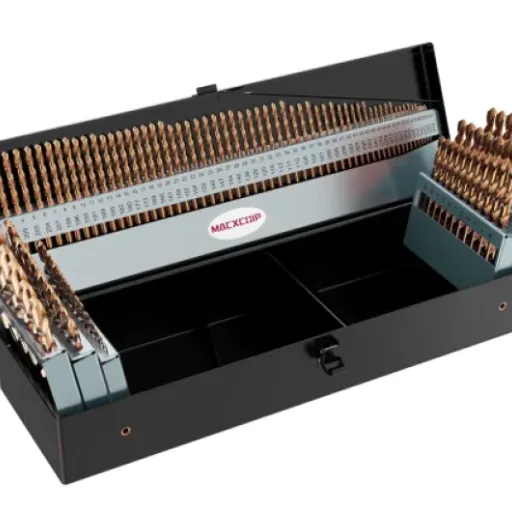

A complete drill socket set is more than a handful of sockets in a box. It usually combines a driver drill compatible shank, one or more drill adapter pieces, several extension bars, and a range of socket sizes in both short and long sleeve formats. Each component must handle the torque drill output without twisting, cracking, or slipping under load.

The shank is the first critical interface, because it locks into the drill chuck or quick release driver. Hex shank designs allow quick view of orientation and fast bit changes, while round shanks suit older hand power drills that rely on keyed chucks. When you add an adapter drill or reduction adapter, you convert that shank into a square drive that accepts standard socket driver pieces.

Extensions help you reach recessed bolts where a normal drill socket would collide with surrounding material. A heavy duty extension with an impact rated sleeve can safely transmit the blows from an impact drill or compact impact wrench. For lighter tasks, a slim extension improves access without adding much weight, which is helpful when you shop products for overhead work.

Many cordless drill set buyers focus only on price, but the internal design of each product matters. Look for quality products that use chrome vanadium or similar high grade alloys, because these resist deformation when orders shipped to busy sites face daily abuse. When comparing brands, use a detailed quick view of specifications and consider how each socket drill piece will interact with your existing measuring tools, torque settings, and cordless platforms from different manufacturers, including those discussed in this guide to choosing the right Milwaukee tools set.

Matching drill socket sets to cordless drill power and torque

Not every drill socket is suitable for every cordless drill, especially when torque levels rise. A compact driver drill used for furniture assembly exerts far less stress on a socket drill than a heavy duty impact drill driving coach screws into structural timber. Matching the grade of your sockets, extensions, and adapters to the torque drill rating is essential for safety.

Impact rated sockets and drill adapter pieces are engineered with thicker walls, tougher alloys, and often a duller finish. These impact rated products are designed to flex slightly under the blows of an impact wrench or impact drill, rather than shattering. When you pair non impact sockets with an impact wrench or high speed torque drill, you risk cracked sleeves, flying fragments, and damaged shank interfaces.

For light duty work, a standard drill socket set with a basic socket driver and short extension is usually sufficient. Tasks like assembling cabinets, fixing brackets, or maintaining bicycles rarely push a cordless drill beyond moderate hand power levels. In these cases, focusing on compact size, quick change features, and clear quick view markings may matter more than extreme durability.

However, automotive maintenance, decking, and structural framing demand heavy duty socket drill kits and robust adapter drill components. Here, the extra price of quality products quickly pays back through fewer failures and safer operation. When evaluating any product, read technical data, check whether it is impact rated, and compare real world reviews, such as those found in this detailed review of a combi drill for DIY and light professional jobs, before placing orders shipped to your workshop.

Practical applications where a drill socket outperforms hand tools

There are many situations where a drill socket dramatically outperforms a traditional hand wrench. When you face long coach screws, rusted nuts, or repetitive assembly work, a cordless drill with the right socket drill accessories can save minutes on every fastener. Over a full day, that time saving translates into less fatigue and more consistent results.

In construction, a driver drill with a heavy duty drill socket set is ideal for fixing structural brackets, tightening anchor bolts, and assembling modular framing. A suitable extension and reduction adapter allow you to reach fasteners hidden behind cladding or within service voids. Because the torque drill delivers controlled power, you can combine speed with accuracy, especially when supported by measuring tools that confirm correct tension.

Automotive and mechanical maintenance also benefit from impact rated socket driver kits. A compact impact drill or small impact wrench equipped with a robust adapter drill can loosen wheel nuts, engine mounts, and suspension components that would exhaust hand power alone. Here, a strong sleeve and shank interface prevent twisting, while quality products steel resists rounding under repeated loads.

Even in domestic settings, a modest drill socket set can transform flat pack furniture assembly and garden equipment maintenance. Instead of juggling multiple tools, you rely on one driver drill, a few sockets, and perhaps a flexible extension for awkward corners. When you shop products for these tasks, pay attention to product descriptions, price transparency, and whether orders shipped include storage cases that support simple inventory management at home.

Evaluating quality, price, and delivery when buying drill socket sets

Choosing a drill socket set is ultimately a balance between quality, price, and practical delivery conditions. Professional users often prioritise heavy duty, impact rated products, while occasional users may focus on affordable socket drill kits that still meet basic safety standards. In both cases, understanding what lies behind the price tag helps you make a rational decision.

Quality products usually specify the steel grade, surface treatment, and tested torque limits. Look for clear information about whether the drill socket, extension, and drill adapter are suitable for impact drill or impact wrench use. Transparent brands also state if the shank is designed for quick release chucks, which supports quick view changes between a socket driver and standard bits.

Delivery terms matter more than many buyers realise, especially when orders shipped must reach remote sites or tight project schedules. Reliable suppliers indicate typical delivery times, packaging standards, and how they handle damaged product returns. For workshops with structured inventory management, consistent packaging and labelling make it easier to shop products repeatedly without confusion.

Online platforms increasingly integrate social proof, including facebook youtube demonstrations of drill socket performance under real conditions. These videos can reveal how a torque drill handles heavy duty loads with different socket driver sets and adapter drill designs. When comparing brands, consider not only the initial price but also long term durability, availability of spare sleeves or extensions, and how easily you can expand your measuring tools and accessories around the same cordless ecosystem, as discussed in this article on the versatility of Milwaukee drills.

Safe use, maintenance, and organisation of drill socket equipment

Safe use of a drill socket begins with matching the accessory to the task and tool. Always confirm whether your socket drill pieces and drill adapter are impact rated before using them with an impact drill or impact wrench. Misuse can lead to cracked sleeves, damaged shank connections, and serious injury from flying fragments.

Routine inspection is essential, especially for heavy duty workshop environments where orders shipped arrive frequently and tools circulate between teams. Check each product for hairline cracks, rounded corners, or distorted extensions, and remove any suspect items from service. A disciplined approach to inventory management ensures that only sound quality products remain in active rotation.

Cleaning and light lubrication help preserve both sockets and driver drill chucks. Wipe away debris after use, apply a thin oil film to prevent corrosion, and store each drill socket, extension, and reduction adapter in its designated sleeve or case. This care supports consistent high speed performance and reduces the risk of a stuck socket driver during urgent work.

Organisation also improves productivity, because a clearly arranged drill socket set allows quick view identification of sizes and drive types. Group impact rated accessories separately from standard ones, and label storage so that even new staff can select the correct adapter drill or torque drill setting. Whether you are a professional technician or a careful home user, combining safe practice, regular maintenance, and thoughtful storage will keep your hand power tools, measuring tools, and cordless systems working efficiently for many years.

Key statistics about cordless drills and socket use

- Up to 60 % of fastening time on site can be saved when replacing a manual wrench with a correctly matched drill socket and driver drill combination.

- Impact rated socket drill sets typically withstand torque levels that are 30 % to 50 % higher than non impact alternatives of similar size.

- Workshops that implement basic inventory management for sockets and adapters report tool loss reductions of around 25 %.

- Heavy duty cordless impact drill models can deliver more than 200 newton metres of torque, which requires appropriately graded drill socket accessories.

Common questions about drill socket sets for cordless drills

How do I know if a drill socket is impact rated ?

Manufacturers usually mark impact rated sockets with clear labels, darker finishes, or specific series names, and they state compatibility with impact drill and impact wrench tools in the product description. If the packaging or online quick view does not explicitly mention impact use, assume the socket drill is for standard driver drill applications only. When in doubt, choose clearly rated heavy duty accessories to avoid premature failure.

Can I use any socket with my cordless drill ?

You can use many standard sockets with a cordless drill if you have the correct drill adapter or adapter drill that converts the shank to the appropriate square drive. However, non impact sockets should only be used with moderate torque drill settings and without hammer action. For demanding tasks, select impact rated drill socket sets designed for power tools rather than hand power only.

What sizes should a basic drill socket set include ?

A versatile starter kit should cover common metric sizes used in furniture, construction, and automotive work. Many users choose a drill socket set that includes 8 millimetre to 19 millimetre sockets, one or two extensions, and a universal socket driver adapter. This range allows a single driver drill or impact drill to handle most household and light professional fastening jobs.

How important is storage for sockets and adapters ?

Good storage is vital for both safety and efficiency, because loose sockets are easily lost or damaged. A labelled sleeve, rail, or case supports simple inventory management and faster selection of the correct drill socket or reduction adapter. Over time, organised storage reduces replacement costs and helps keep your quality products ready for immediate use.

Do social platforms really help when choosing drill socket products ?

Videos and reviews on platforms such as facebook youtube can provide useful real world demonstrations of drill socket performance. Watching how a particular socket driver or adapter drill behaves with a torque drill under load often reveals strengths and weaknesses that static photos cannot show. Combine these impressions with technical specifications and trusted retailer information before placing orders shipped to your home or workshop.