Understanding Plastic Drill Bits

Demystifying Plastic Drill Bits

When it comes to drilling through plastic, selecting the appropriate drill bit is crucial for success. Plastic drill bits are specifically designed to handle materials like acrylic and other plastics without causing damage or cracking. These bits often have different characteristics compared to those used for wood or metal, focusing on features that adapt well to the unique properties of plastics.

One of the key considerations in choosing a suitable drill bit size is the distinct material properties of plastics, such as their tendency to crack or chip if not handled properly. The design of plastic drill bits typically includes a sharper point and specific point rake angles to efficiently create clean holes in plastics. Additionally, these bits help in preventing the plastic from melting or getting clogged within the bit during the drilling process.

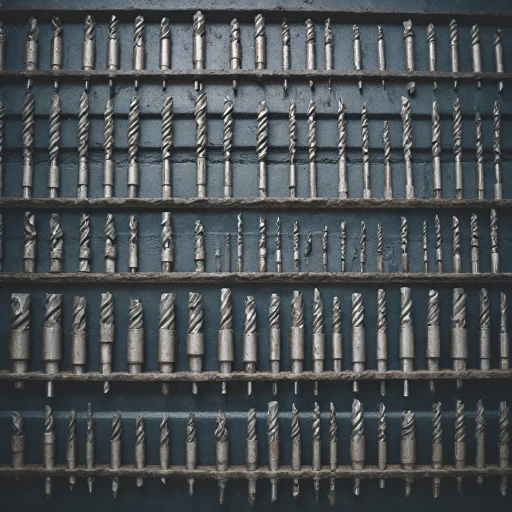

Plastic drill bits are available in various sizes and configurations, including the popular step drill bits, which allow for drilling different sized holes in a single action. This adaptability makes them particularly useful for creating precise, clean holes without the need for multiple tools or repeated changes in bit size. Understanding these features helps ensure that your cordless drill set is well-equipped to handle the task of drilling plastic effectively.

Keep in mind that while selecting the right bits is essential, the method of usage also plays a crucial role. As you delve deeper into techniques for drilling and maintaining your drill bits, attention to detail and proper execution will ensure the best results in your projects involving plastic materials.

Compatibility with Cordless Drill Sets

Compatibility Considerations for Cordless Drill Sets

Selecting the right drill bit for your cordless drill set often requires careful attention to compatibility. Understanding the relationship between your drill and bits can significantly influence the success of your drilling endeavors, particularly when working with delicate materials like plastic and acrylic. When pairing drill bits with your cordless drill, a few factors come into play:- Size and Chuck Capacity: Cordless drills usually come equipped with chucks of varying sizes, commonly 3/8-inch or 1/2-inch. Ensure the size of the bit shank aligns with the chuck size to guarantee a secure fit.

- Material-Specific Bits: For drilling plastics, opt for bits specifically designed for such tasks to prevent cracking and ensure clean edges. Selecting a plastic drill bit or step drill can lead to more efficient drilling, especially in delicate materials like acrylic plastic.

- Drill Speed Settings: Cordless drills often feature variable-speed controls, which can be crucial when drilling plastics. Too high of a speed can generate heat, causing damage to the material and affecting the drilled hole quality.

Selecting the Right Bit for Your Project

Choosing the Perfect Bit for Your Task

Securing the ideal drill bit for your project is essential for achieving precise results when working with plastics. Consider the following factors to ensure you select the most suitable bit:

- Material Compatibility: Ensure that the drill bits you select are specifically engineered for plastics. Different tools, such as standard bits for wood or metal, may not provide clean cuts or might damage the material. Opt for bits plastic to prevent cracking and avoid splintering when creating a drilled hole.

- Size and Diameter: Confirm the size of the hole you need to create and select a drill bit that matches. For acrylic plastics, ensuring the correct bit size is crucial to achieving a seamless fit and preventing unwanted gaps.

- Drill Type: A step drill might be more advantageous when working on projects requiring holes of varying diameters. Step drills allow for incremental drilling, which is ideal for plastics compared to other types like wood or aluminum.

- Drill Point Design: Consider the point rake of your bit. Point bits designed for plastics reduce the risk of cracking and ensure smoother penetration into the material. This design enables efficient removal of material, facilitating more effective drilling plastic processes.

Remember to use a drill setting that aligns with the material's resistance, as drilling speed and pressure play pivotal roles in the outcome. It's highly recommended to master specific drilling techniques that cater to your project's unique needs to maintain the integrity of the material being worked on.

Techniques for Drilling Plastic

Essential Steps for Drilling into Plastic

When drilling into plastic, certain techniques will ensure a clean hole without cracking or damaging the material. Here's a guide to help you navigate this process effectively.- Choose the Correct Drill Bits: Opt for step drills or point bits specifically designed for plastic. These bits drill clean, precise holes by gradually enlarging the hole size. Avoid using bits for aluminum wood or other materials, as they may not perform well on plastics.

- Secure the Material: Before you begin, clamp the plastic securely using tools or a vice. This prevents the material from moving and ensures a clean drill hole.

- Adjust Drill Speed: Plastic requires a slower drill speed than wood or metal. A low-speed setting on your cordless drill will reduce heat build-up, which can lead to melting or cracking.

- Start with a Pilot Hole: To prevent cracking, begin by drilling a small pilot hole. This initial step guides the drill bit and minimizes stress on the plastic.

- Use Minimal Pressure: Applying too much force can cause the plastic to crack. Let the drill do the work and maintain a steady hand for best results.

- Clean and Deburr: After drilling plastic, clean out the drilled hole and remove any debris or rough edges with a deburring tool. This step ensures the finish is smooth and ready for your application.

Maintenance and Care of Drill Bits

Best Practices for Keeping Your Drill Bits Sharp

Maintaining the razor-sharp edge of your drill bits is crucial for effective drilling in plastic materials, like acrylics. A sharp bit minimizes friction, ensuring a clean drill and reducing the risk of causing cracks in the plastic.

- Regular Inspection: Periodically check your drill bits for wear and tear. Look out for signs of dullness or damage on the tool’s points, especially after heavy-duty drilling sessions.

- Cleaning: After using your bits, especially for drilling plastics or wood, clean them thoroughly to remove any debris or cutting residue. This helps in maintaining clear rake angles on point bits, ensuring efficient drilling.

- Proper Storage: Keep your bits organized and protected in a tool box or storage set. This prevents damage to the bit edges and contaminations that might hinder performance.

Preventing Overheating

Overheating is a common pitfall that may lead to the degradation of drill bits. To preserve the longevity of your tools, consider the following:

- Cooling: Use a coolant or lubricant spray when drilling to dissipate heat effectively, especially in high-friction materials like acrylic or plastics.

- Moderate Speed: Adjust the speed of your cordless drill to avoid excessive friction. High-speed drilling in plastics can increase chances of overheating.

- Pulsing Technique: Apply a pulsing motion with your drill. This intermittent approach allows the bit to cool between drilling actions and reduces the chance of material melting or cracks forming.

Secure Handling and Proper Techniques

Proper handling and operating techniques further contribute to the durability of your drill bits:

- Use Appropriate Pressure: Apply steady, controlled pressure when drilling to prevent snapping or premature wear. The stress on the drill should be just enough to make progress into the material without stalling.

- Point Angle Adjustment: For drilling plastics and acrylic, ensure the drill bit has an appropriate point rake angle. This promotes cleaner holes with minimal burrs.

- Step Drills: When working on larger diameter holes in delicate materials, consider step drills. They are designed to reduce the chipping associated with plastics, providing smoother, cleaner drilled holes.

Common Mistakes to Avoid

Avoiding Common Pitfalls in Plastic Drilling

When embarking on a plastic drilling project, many encounter a variety of common mistakes that could be easily avoided. Here is a detailed view of these missteps with suggestions on how to steer clear of them, ensuring a clean and precise drilled hole.

Choosing the Wrong Drill Bit

Picking the wrong drill bit could lead to uneven drilling or even damage to the material. For plastics, a step drill or point bit is often preferred due to its clean cutting ability, helping to prevent cracking. Make sure to select a bit that suits the size of the holes you aim to create.

Ignoring Drill Speed

Drilling at an incorrect speed is a common mistake, especially with tools like a cordless drill. A slower speed is usually recommended for plastics to reduce friction and heat that could warp or melt the material. Consult your drill's manual to properly set the speed, adjusting it as necessary for different plastics such as acrylic.

Improper Support

Failing to provide adequate support beneath the plastic can lead to cracking or deformation during the drilling process. Always place the plastic on a firm surface, perhaps a piece of scrap wood or aluminum, to prevent the plastic from flexing or breaking.

Skipping Pre-drilling

Many neglect to start by making a small pilot hole, especially when working with harder plastics. This initial step helps in guiding the bit accurately into its desired position, and reduces the chances of the drill slipping, ensuring precise holes.

Neglecting Maintenance

Proper maintenance and care of your drill bits is crucial for successful projects. Bits that are not sharp or are blocked with debris will have detrimental effects on the outcome. Take the time to clean your drill bits after each use and regularly check for signs of wear.

By avoiding these frequent mistakes and employing the correct techniques, the drilling process will not only be smoother but you'll achieve cleaner and more reliable results.