The Role of Hole Drill Bits in Cordless Drill Sets

The Essential Function of Hole Drill Bits in Cordless Drill Sets

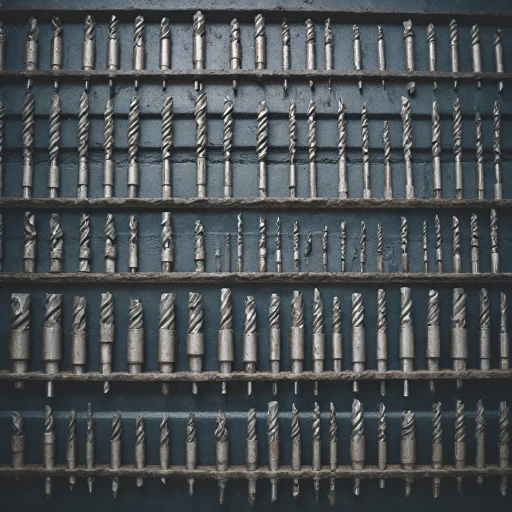

Hole drill bits are a crucial component of any cordless drill set, offering versatility and precision in various drilling tasks. These bits are designed to create holes in a wide range of materials, from wood and metal to more challenging surfaces like tile and glass. The ability to switch between different types of hole drill bits makes a cordless drill set an indispensable tool for both professional tradespeople and DIY enthusiasts.

One of the key advantages of using hole drill bits is their adaptability. Whether you're working with a high-speed steel bit for metal or a diamond hole bit for cutting through tough materials, the right bit can make all the difference in achieving a clean, precise cut. The Milwaukee hole dozer and diamond hole saws are popular choices for those needing to tackle more demanding projects.

In addition to their versatility, hole drill bits are designed for easy set and quick changes, allowing users to switch between tasks without losing momentum. This feature is particularly beneficial when working with a hole jig or set pocket systems like the Kreg pocket hole kit, which require precise and consistent hole placement.

For those looking to expand their toolkit, understanding the different types of hole drill bits and their specific applications is essential. This knowledge not only enhances the efficiency of your cordless drill set but also ensures the longevity of your tools. For more insights on selecting the right drill bit for your needs, consider exploring choosing the right drill bit for your cordless drill set.

Types of Hole Drill Bits and Their Applications

Exploring Various Hole Drill Bit Types

When it comes to cordless drill sets, understanding the different types of hole drill bits and their specific applications can significantly enhance your project outcomes. Each bit is designed for a particular material and purpose, ensuring precision and efficiency.

Twist Drill Bits

Twist drill bits are the most common type, ideal for general-purpose drilling. Made from high-speed steel, they are suitable for wood, plastic, and light metal. Their spiral design helps in easy cutting and removal of debris.

Spade Bits

Spade bits are perfect for drilling large holes in wood. They feature a flat blade with a center point and are often used in woodworking projects. Their design allows for quick and easy hole creation.

Hole Saws

Hole saws are used for cutting larger diameter holes. They consist of a steel cylinder with saw teeth and are ideal for creating holes in wood, plastic, and metal. Milwaukee hole saws, for instance, are known for their durability and precision.

Forstner Bits

Forstner bits are used for creating clean, flat-bottomed holes in wood. They are excellent for woodworking projects that require precision, such as making pocket holes or using a hole jig.

Diamond Hole Saws

Diamond hole saws are designed for cutting through hard materials like tile and glass. Their diamond-coated edges ensure a smooth cut, making them a valuable tool for specialized projects.

Step Drill Bits

Step drill bits are versatile tools that can drill holes of various sizes without changing bits. They are particularly useful for thin materials like sheet metal, offering a quick change between sizes.

For a comprehensive guide on selecting the right drill bits for your cordless drill set, visit Choosing the Right Drill Bits for Your Cordless Drill Set.

Choosing the Right Hole Drill Bit for Your Project

Identifying the Perfect Drill Bit for Your Needs

Choosing the right hole drill bit for your project can significantly impact the quality and efficiency of your work. With a variety of bits available, understanding their specific applications is crucial. Whether you're working with wood, metal, or masonry, selecting the appropriate bit ensures precision and ease.

First, consider the material you'll be drilling into. For wood projects, a spade bit or a hole saw might be ideal, while metal requires high-speed steel or cobalt bits. If you're tackling masonry, a carbide-tipped bit is essential for durability and effectiveness.

Understanding Bit Types and Their Features

Each bit type has unique features designed for specific tasks. For instance, a diamond hole bit is perfect for cutting through hard surfaces, while a Milwaukee hole dozer is excellent for heavy-duty applications. The kreg pocket hole jig is another popular choice for creating precise pocket holes in woodworking.

Consider the speed and cutting capabilities of the bit. High-speed steel bits are versatile and can handle a range of materials, while quick change bits offer convenience and efficiency during projects. Additionally, bits with etched markings provide easy depth measurement, ensuring accuracy in your work.

Matching the Bit to Your Drill

Ensure compatibility between your drill and the bit. Some drills require specific shank sizes or types, such as a set collar for stability. Additionally, consider the center and radial alignment of the bit to prevent wobbling and ensure a clean cut.

For more insights on mastering the art of using your drill set effectively, check out this guide.

Maintenance Tips for Hole Drill Bits

Keeping Your Hole Drill Bits in Top Shape

Maintaining your hole drill bits is crucial for ensuring their longevity and performance. Proper care not only extends the life of your tools but also enhances the quality of your work. Here are some essential tips to keep your drill bits in excellent condition:

- Regular Cleaning: After each use, clean your drill bits thoroughly to remove any debris or material residue. This prevents buildup that can dull the cutting edges.

- Proper Storage: Store your bits in a designated drill bit set or case. This prevents them from banging against each other, which can cause nicks and damage. Consider using a set collar or hole jig for organized storage.

- Sharpening: Over time, even high-speed steel and diamond hole bits can become dull. Use a sharpening tool to maintain the cutting edge. This is especially important for bits used on hard materials like metal or when using a hole saw.

- Lubrication: When drilling through tough materials, use a lubricant to reduce friction and heat. This helps in preserving the integrity of the bit and ensures smooth cutting.

- Inspect for Damage: Regularly check your bits for any signs of wear or damage, such as chips or cracks. Replace any compromised bits to avoid compromising your projects.

- Use the Right Speed: Adjust the speed of your cordless drill according to the material you're working with. High-speed settings can wear out bits faster, especially when drilling into metal.

By following these maintenance tips, you can ensure that your hole drill bits remain effective and ready for any project. Whether you're using a Milwaukee hole dozer or a Kreg pocket hole jig, proper care is key to achieving precise and clean cuts.

Safety Considerations When Using Hole Drill Bits

Prioritizing Safety with Hole Drill Bits

When using hole drill bits, safety should always be at the forefront of your mind. Whether you're working with a high-speed steel bit or a diamond hole saw, understanding the risks and taking appropriate precautions can prevent accidents and ensure a smooth drilling experience.

- Wear Protective Gear: Always wear safety goggles to protect your eyes from flying debris. A dust mask can also be beneficial, especially when working with materials that produce fine particles.

- Secure Your Material: Use a jig or a set collar to hold your material firmly in place. This prevents the material from spinning or moving, which could lead to inaccurate cuts or injury.

- Check Your Tools: Before starting, inspect your drill and bits for any signs of wear or damage. A damaged bit can break during use, posing a significant safety hazard.

- Mind the Speed: Adjust the speed of your drill according to the material you're working with. High-speed settings are suitable for softer materials, while harder materials may require slower speeds to prevent overheating and damage to the bit.

- Use the Right Bit: Ensure you're using the correct bit for your project. For example, a Milwaukee hole dozer is ideal for cutting through metal, while a kreg pocket hole bit is better suited for woodworking tasks.

- Stay Focused: Keep your attention on the task at hand. Distractions can lead to mistakes, which are not only costly but potentially dangerous.

By following these safety considerations, you can effectively minimize risks and make the most of your cordless drill set. Remember, safety is not just about protecting yourself but also about ensuring the longevity and performance of your tools.

Innovations in Hole Drill Bit Technology

Advancements in Hole Drill Bit Design

The world of hole drill bits has seen significant innovations, making them more efficient and versatile than ever. These advancements cater to a wide range of materials and applications, enhancing the overall performance of cordless drill sets.

High-Speed Steel and Diamond Coatings

One of the most notable innovations is the use of high-speed steel and diamond coatings. High-speed steel drill bits offer superior durability and heat resistance, making them ideal for cutting through tough materials like metal. Diamond-coated bits, on the other hand, provide exceptional cutting precision and longevity, especially when working with hard surfaces such as ceramics and glass.

Quick Change Systems

Quick change systems have revolutionized the way we use drill bits. These systems allow for fast and easy swapping of bits, reducing downtime and increasing productivity. This feature is particularly beneficial when working on projects that require multiple bit sizes or types, such as using a hole saw for larger openings or a pocket hole jig for joinery tasks.

Etched Markings for Precision

Precision is key in any drilling task, and etched markings on drill bits have become a standard feature. These markings help users identify the size and type of bit at a glance, ensuring the right tool is used for the job. This is especially useful when working with a comprehensive drill bit set, where organization and quick identification are crucial.

Innovative Hole Jigs and Kits

Hole jigs and kits have also seen improvements, offering more versatility and ease of use. Modern hole jigs are designed to work seamlessly with cordless drill sets, providing stability and accuracy when drilling. These tools are essential for creating consistent and precise holes, whether you're using a kreg pocket hole jig or a set pocket hole kit.

Enhanced Safety Features

Safety is always a priority, and new drill bit designs incorporate features to minimize risks. For instance, some bits come with set collars to prevent over-drilling, while others are designed to reduce radial torque, making them safer to use at high speeds. These innovations not only protect the user but also extend the life of the drill bits.

As technology continues to evolve, we can expect further advancements in hole drill bit technology, making them even more efficient and user-friendly. Whether you're a professional or a DIY enthusiast, staying informed about these innovations will help you make the most of your cordless drill set.