Understanding Rivet Types and Their Challenges

Identifying the Rivet Variability

Rivets, those small but mighty fasteners, play a critical role in the assembly of materials. Their versatility is why you find them commonly used across various sectors from construction to aerospace. However, understanding the type of rivets you're dealing with is crucial for successful removal.

Rivet Materials and Their Impact

The material makeup of rivets significantly impacts the removal process. Standard options include steel, stainless steel, and aluminum. Each of these materials presents unique challenges. For instance, stainless steel rivets require a more robust tool due to their tougher composition. In contrast, aluminum rivets are softer, necessitating a different approach.

A Diverse Range of Rivet Heads

Beyond material, rivet head types like countersunk, flat, or dome also dictate the best removal technique. A pop rivet typically features a dome head, perfect for two-sheet metal applications, while blind rivets are employed where only one side of the workpiece is accessible. Knowing the rivet head type will guide your choice of drill bit and removal tool, enhancing efficiency.

Challenges in Rivet Removal

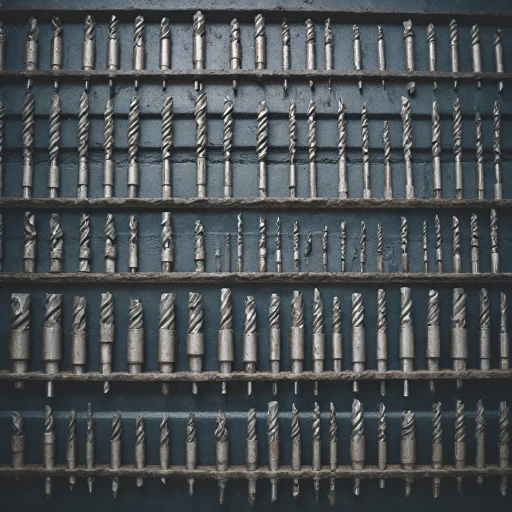

Rivet removal isn't just about drilling out the head. You must consider the drill bit size, which should match the rivet's diameter. Incorrect sizing can lead to imprecise drilling, damaging the sheet metal or the material beneath. A quick change drill bit set is worthwhile, offering adaptability across different rivet types and sizes.

Selecting the Ideal Drill Bit for Rivet Removal

Selecting the Appropriate Drill Bit for Rivet Removal

Choosing the right drill bits is crucial for effective rivet removal. When dealing with different types of rivets, including pop rivets, blind rivets, and those made from materials like stainless steel, your drill bits must be up to the task. The first step is to assess the size and material of the rivet head. If you're working with small rivets or those made from tough materials such as steel, you’ll need a bit that offers durability and precision. A drill bit made of high-strength materials, such as cobalt or titanium-coated steel, can efficiently cut through stainless steel rivets. It's also important to consider the bit's tip design; a split point tip can prevent wandering and allow for precise starting holes, which is essential for avoiding damage to the surrounding material. When buying bits, take note of the diameter required for the rivet drill; it's often slightly larger than the rivet shank to effectively drill hole for removal. Additionally, a quick change capability can save you time and frustration during the bit rivet process. Although price and accessibility on platforms like Amazon can factor into decisions, the quality and compatibility of the drill bit plays a pivotal role. Investing in a quality set might have an upfront cost, but it saves time and extends the life of your tools. For more insights on selecting the ideal drill bits tailored to your needs, explore the importance of masonry drill bits for cordless drill sets.Features to Look for in a Cordless Drill Set

Key Features to Consider for Optimal Performance

When it comes to selecting a cordless drill set capable of tackling rivet removal, several features stand out. These attributes ensure that your tool provides not only efficiency but also durability and precision as you manage the challenges associated with different rivet types. 1. Power and Performance A robust cordless drill with ample power is essential, especially when dealing with stainless steel or other tough metals. Look for a drill that can maintain torque without losing battery life rapidly. A lithium-ion battery provides consistent power, resulting in more efficient rivet head penetration. 2. Quick-Change Chuck System A quick-change system allows for seamless swapping of drill bits, which is crucial when dealing with varying sizes of rivets. This feature minimizes downtime during tasks, especially when switching between different bit sizes to accommodate different rivet diameters found on products available on platforms like Amazon. 3. Variable Speed and Torque Settings Having control over speed and torque is vital. Variable speed allows for precision when engaging with delicate sheet metal or pop rivets, while adjustable torque settings guarantee that your tool doesn't strip rivet holes. 4. Compatibility with Drill Bits for Metal Ensuring that your cordless drill set can accommodate bits specifically designed for metal surfaces is essential. Consider a set that includes drill bits for metal to tackle varying material compositions such as aluminum or stainless steel effectively. For more detailed insights on mastering usage of your drill set in such applications, understanding compatibility is key. 5. Ergonomic Design Efficiency in rivet removal involves prolonged handling of the tool. An ergonomic design ensures comfort and reduces fatigue, allowing for smoother operations when removing multiple rivets or blind rivets. This aspect is crucial when precision is required in rivet removal scenarios where the wrong angle can compromise the result. These features not only enhance the ease of use but also ensure the durability of the tool under repeated stress, which is especially important when dealing with small rivet heads or pop rivets. Keep these considerations in mind to maximize both the effective performance and longevity of your cordless drill set, making rivet removal a streamlined task.Techniques for Safe and Efficient Rivet Removal

Skillful Techniques for Removing Rivets Safely and Efficiently

Removing rivets might seem straightforward, but there's a technique to it to ensure you do it right without damaging the surrounding materials. This section delves into practices that will help you navigate the process safely and with maximum efficiency. Begin by securing your workspace. Ensure you have sufficient lighting and that your work area is stable to prevent any mishaps. When dealing with rivets, particularly those made from metal or stainless steel, drilling accurately into the rivet head is crucial. Identify the center of the pop rivet head, as this will be your drill's entry point. For securing the best outcome, use a drill bit that matches the size of the rivet shank. If you're using an electric drill, set it to the appropriate speed settings, which typically means starting slow. This way, you minimize the risk of the bit skidding off the rivet head and scratching the metal sheet or material underneath. Once your drill bit is set and centered, apply steady pressure and begin to drill into the rivet head. Be patient; don't rush the process to avoid overheating the bit or damaging the surrounding area. For blind rivets or pop rivets, be aware that you might need to apply a bit more pressure as the drill penetrates the metal body. For those dealing with stainless steel, opting for a cobalt drill bit may offer better results due to its durability and heat resistance. With a steep price tag compared to standard bits, these cobalt tools can significantly enhance the efficiency of your rivet drill tasks. Quick change tool sets can make transitions between different drill bits seamless, saving time and headache, particularly when working with varying sizes and types of rivets. Whether removing rivet heads made of aluminum or dealing with stubborn steel rivets, ensure you have a comprehensive tool set that caters to various challenges you might face. Finally, always wear safety gear. Eye protection is paramount when bits of metal or pop rivet shavings might splash during the rivet removal. Taking these precautions not only protects you but ensures that the task of rivet removal is executed with precision and efficiency.Maintenance Tips for Your Drill Bits and Cordless Drill

Effective Strategies for Long-Lasting Drill Bits

To maintain the efficiency of your drill bits and cordless drill set, proper care is essential. Here are some proven strategies to ensure your rivet removal tool stays in top shape:

- Regular Cleaning: After each use, make it a habit to clean your drill bits and tools. This involves removing any metal shavings, debris, or dust that might have accumulated during the drilling process. This is particularly important when working with sheet metal or stainless steel as these debris can affect the tool’s performance.

- Lubrication: Using appropriate lubricants minimizes heat friction on the bit and tool rivet. This reduces wear and tear on your drill head, significantly extending the life of your drill bits and ensuring smooth rivet removal.

- Proper Storage: Storing your tools properly prevents unnecessary wear caused by accidental drops or rust formation. Consider investing in a quick change storage system to keep your bits organized and easily accessible. Avoid leaving them in damp or humid conditions.

- Inspection Before Use: Frequently inspect your drill and bits for any signs of damage, such as cracks or dullness. For instance, a cobalt bit losing its edge could pose challenges during the removal of pop rivets or blind rivets.

- Sanding and Sharpening: Keep bits in prime condition by sanding or sharpening them regularly. A dull bit can cause slips during drilling, which may lead to inaccuracies or safety hazards during rivet drill processes.

Maintaining your drill bits is as important as selecting the right one for your project. If you’re consistently using your drill for metal applications like stainless steel or sheet metal, periodic maintenance ensures optimum performance and value for the price you’ve invested in your set.

Common Mistakes to Avoid When Removing Rivets

Missteps That Could Complicate Your Rivet Removal Process

Navigating the intricacies of rivet removal can be a tricky endeavor. From drill bit selection to applying the appropriate techniques, ensuring precision is essential. Here are some common mistakes to avoid during the removal process:- Inappropriate Drill Bit Selection: Opting for a generic drill bit instead of one designed for rivets may lead to inefficient removal and potential damage to the material being worked on. It's crucial to choose the right bit, especially one that suits the material like stainless steel or sheet metal.

- Ignoring Drill Bit Size: Using a drill bit that’s too large or too small can result in an ineffective rivet head removal, possibly leaving behind fragments or damaging the surrounding area. Precise sizing is vital for neat and efficient pop rivet removal.

- Overlooking the Drill's Power Settings: An electric drill with incorrect power settings could lead to unnecessarily forcing the bit, which might cause it to slip or break. Adjust your cordless drill appropriately to match the material density and rivet type.

- Neglecting Drill Angle: Maintaining a stable, perpendicular angle to the rivet surface helps ensure smooth drilling. A misaligned drill can create an unintended drill hole or damage the surrounding metal sheet.

- Forgetting Maintenance: Regular maintenance of both your drill and drill bits will ensure longer tool life and better performance. Disregarding cleaning or sharpening can dull the bits, making the removal process inefficient.

- Omitting Use of the Right Removal Tool: Combining the proper removal technique with a specialized removal tool enhances efficiency. Tools like a quick change rivet removal tool can drastically improve the operation.