Understanding Hardened Steel

{"": "Deciphering the Challenges of Hard Steel"

Drilling through hardened steel, a type of metal known for its immense strength and endurance, poses a unique challenge. This material is often used in applications that require more durability and resistance to wear, such as in industrial settings, construction, and making of tools. Unlike standard metals, hardened steel undergoes a specialized heat treatment process, enhancing its toughness and making it quite difficult to drill through.

Understanding the composition of this metal is crucial before embarking on any drilling endeavors. Cobalt drill bits are often recommended for this task due to their enhanced toughness and ability to retain sharpness over prolonged use, albeit subject to premium pricing. Alternatively, carbide bits offer high wear resistance and are incredibly effective for drilling through such demanding materials. These drill bits are designed specifically to handle the extreme pressure and friction generated during the drilling process.

Choosing the right drill bit size is also essential as it directly impacts the efficiency and success of your drilling task. A bit that is too small may not penetrate the steel effectively, while one that is too large could lead to damage or breakage of the drill bit itself. It's recommended to delve deeper into drill bit specifications and customer reviews when making a decision. Keeping in mind these factors can significantly facilitate smoother drilling operations.

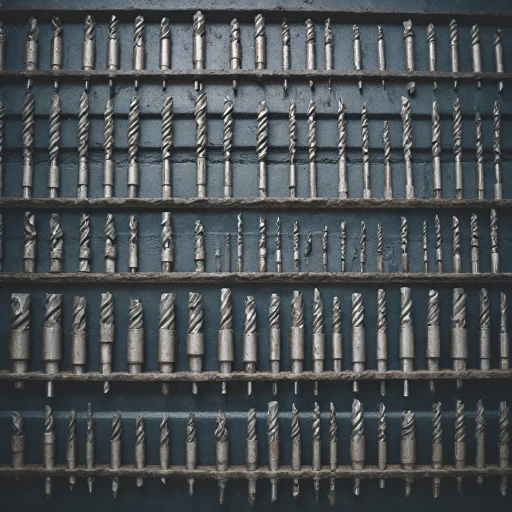

Types of Drill Bits Suitable for Hardened Steel

Exploring Drill Bits for Tough Jobs

When it comes to tackling the uncompromising nature of hardened steel, not all drill bits are created equal. Selecting the right type of bit is crucial for achieving precision and durability in your projects. Here, we delve into some of the most trusted options that have proven effective against such tough materials.- Cobalt Drill Bits: Renowned for their exceptional heat resistance and durability, cobalt bits are a popular choice for drilling through hardened materials. Their cobalt alloy composition enables them to maintain strength and effectiveness even when subjected to intense heat, making them ideal for persistent drilling through hardened steel and stainless steel. You'll often find these bits labelled as "cobalt drills," indicative of their robust nature.

- Carbide Drill Bits: Another formidable contender, carbide bits are revered for their hardness and wear resistance. They exhibit an impressive cutting speed when dealing with hard steel and ensure a longer life span thanks to their capacity to stay sharp. These bits are best utilized when high precision is required, especially when drilling through particularly stubborn metals.

- High-Speed Steel (HSS) Drill Bits: While not inherently suited for the hardest materials, when enhanced with coatings such as titanium or black oxide, HSS bits can offer a viable solution for less demanding hardened steel applications. Their versatility makes them a good choice for drilling through softer metals, but with the right coating, they can tackle more resistant materials.

Features to Look for in a Drill Bit

Key Attributes in Drill Bits Suitable for Hard Steel

Selecting the right drill bit for hardened steel can significantly impact the efficiency and precision of your work. Here are some pivotal features to look for when choosing drill bits suitable for this tough material:- Material Composition: Look for drill bits made of cobalt or carbide. Cobalt drill bits are known for their durability and effectiveness in cutting through hard materials like stainless steel. Their composition offers high wear resistance, making them an ideal choice for drilling through hardened steel. Meanwhile, carbide bits are recognized for staying sharp longer than other materials, providing consistent performance in demanding drilling tasks.

- Tip Design: Consider the drill bit's tip design when drilling tough materials. TTP hard tips are designed to effectively pierce and penetrate hard steels, minimizing the risk of slipping. A split point design can also offer precision and reduce walking across the metal surface.

- Bit Coating: Coatings like titanium nitride enhance durability and improve the heat resistance of drill bits. These coatings are especially beneficial when undertaking tasks that generate significant heat due to friction.

- Flute Design: A well-designed flute, which is the groove on the bit that helps eject material as you drill, is crucial. An efficient flute design will ensure that the drill bit effectively removes shavings while maintaining a consistent cutting speed.

- Size Variety: Having a comprehensive set of drill bits in various sizes allows you to adapt to different project needs. Whether you're drilling through just the surface or need to create deep holes, diverse sizes expand your capability to tackle various tasks with a single set of drill bits.

Using a Cordless Drill for Hardened Steel

Leveraging Cordless Drills for Effective Drilling

Using a cordless drill for drilling hardened steel can offer flexibility and mobility, allowing you to work in a variety of spaces without being tethered by a cord. However, it's crucial to ensure your cordless drill has adequate power and features to take on such tough materials.

When drilling through hardened steel, opting for a drill set with a powerful motor is key. The best cordless drills for hardened materials tend to have higher power ratings, which offers greater torque and penetration capability. Look for models that can adjust speed settings as drilling through hardened steel requires precise control; a slower speed is often needed to avoid overheating the drill bits.

Cobalt drill bits, known for their wear resistance, are an excellent choice alongside cordless drills due to their ability to stay sharp longer. Similarly, carbide bits are another good option, particularly for tougher jobs, as their resilience against wear renders them effective in maintaining performance over extended use.

It is also beneficial to utilize drills with a hammer function when handling very hard steel, although not all cordless models offer this feature. Checking customer reviews can provide insights into which models and features work best for drilling through tough metals.

Remember, maintaining control over your cordless drill is crucial as the process of drilling hardened steel generates considerable force. Ensuring a secure grip and stable posture will facilitate better work accuracy and safety.

Techniques for Drilling Hardened Steel

Effective Drilling Strategies for Hardened Steel

Drilling through hardened steel can be a challenging task, but with the right techniques and tools, including high-quality drill bits and a reliable cordless drill, the process can become more manageable. To help you effectively drill through these tough materials, consider the following strategies:- Start by Marking the Drill Spot: Before you begin, ensure you accurately mark the point where you want to drill. Using a center punch can help prevent the drill bit from sliding off the hard, smooth surface of the steel, allowing for better precision.

- Optimal Drill Speed: Adjusting the speed of your cordless drill is crucial when working with hardened steel. A slower speed is recommended to prevent overheating, which can cause cobalt or carbide bits to wear out prematurely. Keeping the drill at a low to medium speed will enhance the drill bit's performance and lifespan.

- Apply Constant Pressure: Apply consistent and moderate pressure as you drill. Excessive force can lead to breakage of the drill bit or damage to the cordless drill, while too little pressure might impede progress through the hard metal. The objective is to allow the bit to work through the steel efficiently with each rotation of the drill.

- Utilize Lubrication: To reduce friction and heat build-up, it's beneficial to use a suitable lubricant or cutting fluid. This enhances the performance of your drill bits by keeping them cool and ensuring they stay sharp. Proper lubrication also improves wear resistance, promoting longer usability for your cobalt or carbide drill bits.

- Drill In Steps: For thicker sections of hardened steel, drilling in stages with incrementally larger bits is often advantageous. Begin with a smaller pilot hole before gradually increasing the size. This technique helps in managing the penetration of the bit and ensures a smoother drilling process.

Maintenance and Care for Drill Bits

Ensuring Lasting Performance of Drill Bits

Proper maintenance and care for drill bits are crucial when dealing with hard materials like hardened steel. Given the demanding nature of drilling through such tough substances, it's vital to preserve the integrity and efficiency of your drill bits, whether they are cobalt, carbide, or other high-performance options.- Regular inspection: Frequently inspect your drill bits for any signs of wear or damage. Look for chips, dullness, or any irregularities that could affect performance. Customer reviews often highlight the longevity of well-maintained bits.

- Sharpening and re-pointing: Cobalt and carbide bits are renowned for their hardness and wear resistance, essential qualities for drilling through hardened steel. However, they still require periodic sharpening to stay sharp and maintain their cutting ability. Using specialized sharpening tools can restore the cutting edges efficiently.

- Cleaning after use: After drilling, especially through metals like hard steel, clean the drill bits thoroughly. This removes metal shavings and debris that could cause rust or clog the bit’s flutes, hindering its performance.

- Proper storage: Store your drill bits in a dry environment to prevent corrosion. Many professionals suggest organizing them in a drill index or case to keep them accessible and protected.

- Lubrication: Use a lubricating oil while drilling through tough materials to reduce friction and overheating. This not only extends the life of the bit but also ensures smoother drilling.