Understanding diamond drill bits and their applications

What Makes Diamond Drill Bits Unique?

Diamond drill bits stand out from regular drill bits due to their construction and performance. Instead of a traditional metal tip, these bits feature a coating of industrial diamond particles. This makes them exceptionally hard and capable of drilling through tough materials like glass, porcelain, granite, stone, and tile. Unlike regular bits, diamond bits don’t cut with sharp edges—they grind away material, which is why they’re ideal for delicate or brittle surfaces.

Common Applications for Diamond Drill Bits

Diamond drill bits are essential for anyone working with hard or fragile materials. Here are some typical uses:

- Drilling holes in glass, including sea glass for crafts

- Creating clean openings in porcelain or ceramic tile

- Working with granite, marble, or other stone surfaces

- Core drilling for plumbing or electrical installations

- DIY projects that require precision in hard materials

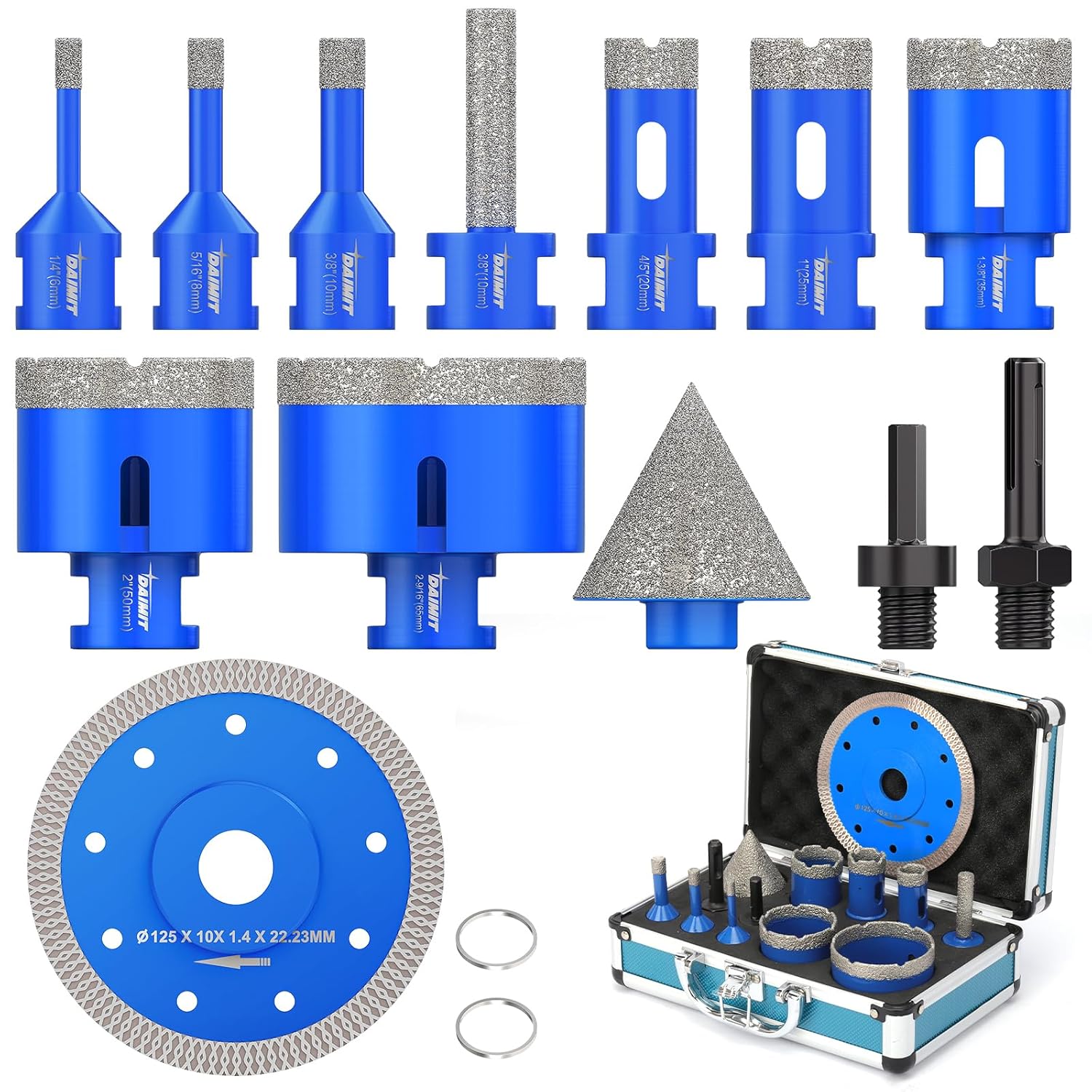

There are different types of diamond bits, such as core bits (which remove a cylinder of material) and small diamond bits for detailed work. Kits often include a range of sizes, from small diameters for jewelry to larger core bits for construction.

Comparing Price and Value

The price of diamond drill bits can vary widely. Factors like the size (inch), quality of the diamond coating, and whether you’re buying a single bit or a full bits set all influence the cost. While the regular price of high-quality diamond bits may seem steep compared to regular drill bits, their performance and longevity often justify the investment. Watch for sale price offers or kits on sale to get the best value. Some kits include multiple pcs for glass, stone, and tile, making them a smart choice for varied projects.

Choosing Between Dry and Wet Diamond Drilling

Some diamond bits are designed for dry drilling, while others require water to cool the bit and reduce dust. Dry diamond bits are convenient for quick jobs or when water isn’t practical, but wet drilling generally extends bit life and improves results, especially with hard materials like granite or porcelain.

Understanding the differences between diamond and regular drill bits, as well as the range of applications, is key to selecting the right tool for your cordless drill set. For a deeper dive into choosing the best drill bit sets for your needs, check out this guide on choosing the right drill bit sets for your cordless drill.

- + Versatile: Suitable for glass, ceramic, porcelain, marble, granite, and stone

- + High-quality: Made with diamond material for durability

- + Variety of sizes: Includes sizes from 1/4" to 1 1/5"

- + Efficient cutting: Designed for clean holes without cracking

Choosing the right diamond drill bit for your cordless drill set

Factors to Consider When Selecting Diamond Drill Bits

When choosing a diamond drill bit for your cordless drill set, it’s important to match the bit to your project’s needs. Diamond bits are designed for hard materials like glass, porcelain, tile, granite, and stone. Unlike regular drill bits, diamond bits use tiny diamond particles to grind through tough surfaces, making them ideal for precise drilling in delicate or hard materials.

- Material Compatibility: Identify the material you’ll be drilling. For glass, sea glass, or porcelain, opt for small diamond bits or bits specifically labeled for glass stone. For granite or hard stone, choose a diamond core bit or dry diamond core bits designed for stone.

- Bit Type: There are several types, including core bits, which remove a cylinder of material, and standard diamond drill bits for smaller holes. A bits kit or bits set can offer a range of sizes, from 1/8 inch to 2 inch, covering most drilling needs.

- Drilling Method: Some diamond bits are made for dry drilling, while others require water for cooling. Dry diamond bits are convenient but may wear faster on hard materials. Always check the manufacturer’s recommendations.

- Price and Value: Diamond drill bits come in various price ranges. Consider the regular price versus sale price, and look for kits or sets on sale for better value. While price diamond bits can be higher than regular bits, their performance on hard materials justifies the investment.

- Kit Contents: A bits kit often includes multiple pcs (pieces) and sizes, which is useful for varied projects. Some kits are tailored for glass, tile, or stone, so check the product description carefully.

Comparing Diamond Drill Bits to Regular Bits

Regular drill bits are suitable for wood and soft metals but struggle with hard surfaces. Diamond drill bits, especially diamond core bits, are engineered for materials that would quickly dull a standard bit. If you’re working with glass, porcelain, or granite, investing in a quality diamond drill bit or bits set is essential for clean, quick, and precise drilling.

Where to Find the Best Diamond Drill Bits

Diamond drill bits are widely available online and in hardware stores. Look for bits glass, bits stone, or diamond core bits for your specific needs. Pay attention to price sale offers and compare the regular price to ensure you’re getting a good deal. For more guidance on selecting the right drill bit set for your cordless drill, check out this resource on choosing the right drill bit hex set.

- + Versatile for hard materials: Works on porcelain, ceramic, granite, marble, stone, and glass

- + Includes multiple sizes: 1/4", 5/16", 3/8", 1/2"

- + Convenient storage case included

- + Durable diamond construction for long-lasting performance

Preparing your cordless drill for diamond drilling

Getting Your Cordless Drill Ready for Diamond Drilling

Before you start drilling into hard materials like tile, glass, or granite with a diamond drill bit, it's important to prepare your cordless drill set properly. This step ensures both safety and the best results, especially when working with a bits kit or a diamond core bit. Here’s how to get started:- Check Compatibility: Not all cordless drills are suitable for diamond core bits or dry diamond drilling. Make sure your drill has adjustable speed settings and enough torque for hard surfaces like porcelain or stone. Some bits, especially small diamond bits, require lower speeds to avoid overheating.

- Choose the Right Chuck: Most diamond drill bits and core bits fit standard chucks, but double-check the size. For example, a 1/4 inch or 3/8 inch chuck is common for bits glass or bits stone. If your bit set includes larger core drill bits, ensure your drill can accommodate them.

- Battery Check: Drilling into hard materials can drain batteries quickly. Use a fully charged battery or have a spare ready. This is especially important if you’re working with a bits set on a big project or using a kit with multiple pcs.

- Secure the Bit: Insert the diamond drill bit or core bit firmly into the chuck. Tighten it to prevent any wobbling, which can damage both the bit and the material, especially when drilling glass stone or sea glass.

- Set the Speed: For diamond drilling, use a low to medium speed. High speeds can overheat the bit and reduce its lifespan. This is true whether you’re using a regular drill bit or a specialized diamond core bit.

- Mark Your Spot: Use masking tape to mark the drilling point on tile or glass. This helps prevent the bit from slipping and makes for a quick, clean start.

- Lubrication: For dry diamond bits, check if lubrication is needed. Some bits are designed for dry use, while others require water to keep the bit cool and extend its life. Always follow the manufacturer’s instructions for your bits kit.

- + Versatile: Suitable for ceramic, glass, porcelain, marble, and granite

- + Includes Cooling Wax: Helps to keep bits cool during use

- + Wide Range of Sizes: 3/16" to 3/8" for different drilling needs

- + Durable Material: Diamond drill bits ensure longevity

- + 1/4" Round Shank: Compatible with most drills

Techniques for effective and safe drilling with diamond bits

Setting Up for Precision and Safety

When working with a cordless drill set and diamond drill bits, preparation and technique are key to achieving clean holes in hard materials like glass, tile, porcelain, granite, or stone. Unlike regular drill bits, diamond bits require a careful approach to avoid damage to both the bit and the material.

- Mark your drilling spot: Use masking tape on smooth surfaces like glass or tile to prevent the bit from slipping. Mark the exact spot with a pen or marker.

- Secure your workpiece: Clamp down the material to keep it steady. For small diamond core bits or bits for sea glass, extra care is needed to avoid cracks or chips.

- Choose the right speed: Set your cordless drill to a low speed. High speeds can overheat the diamond bit and reduce its lifespan, especially with dry diamond drilling.

- Use minimal pressure: Let the diamond drill bit do the work. Applying too much force can break the bit or the material, especially with delicate glass stone or porcelain.

- Keep it cool: For most diamond core bits, especially when drilling hard stone or granite, use water as a lubricant and coolant. This prevents overheating and extends the life of your bits kit. Some dry diamond bits are designed for use without water, but always check the manufacturer's instructions.

- Start at an angle: For a quick start, begin drilling at a slight angle until the bit bites into the surface, then straighten up for a clean, round hole.

Tips for Different Materials and Bit Types

- Glass and sea glass: Use small diamond bits and keep the drill steady. Avoid high pressure and always use water to cool the bit.

- Tile and porcelain: Diamond core bits or bits set for tile work best. Start slow and keep the area wet to avoid cracks.

- Granite and stone: Use heavy-duty diamond core drill bits. These materials are hard, so patience and cooling are essential.

Monitoring Progress and Bit Condition

Check the bit frequently for signs of wear. If you notice the drilling slows down or the bit gets hot, pause and let it cool. Using a bits kit with multiple pcs allows you to switch out worn bits quickly, keeping your project on track.

Remember, the price of diamond drill bits can reflect their durability and performance. Investing in a quality bits set or kit may have a higher regular price, but it often pays off with longer life and better results, especially when compared to regular drill bits on sale at a lower price.

Troubleshooting common issues when using diamond drill bits

Common problems and how to address them

When working with diamond drill bits and your cordless drill set, a few issues can crop up, especially if you’re drilling hard materials like glass, porcelain, granite, or stone. Here’s a quick guide to troubleshooting the most frequent problems:- Bit not cutting efficiently: If your diamond drill bit is struggling to penetrate tile, glass, or stone, check if you’re using the right bit for the material. Regular bits won’t work on hard surfaces—only diamond core bits or small diamond bits are suitable. Also, make sure you’re using the correct speed and applying minimal pressure. Overheating can dull the bit quickly, so consider using dry diamond bits for quick jobs, but for longer drilling, a bit of water can help keep things cool.

- Chipping or cracking: Drilling into glass or porcelain can cause chips or cracks if you go too fast or use the wrong technique. Start with a low speed and let the diamond drill bit do the work. For sea glass or delicate tile, a bits kit with various inch sizes can help you select the best fit for the job.

- Bit slipping on the surface: This is common with smooth materials like glass stone or polished tile. To prevent this, use a guide or create a small indentation with a regular drill bit before switching to your diamond bit. Some bits set kits include a core bit guide for this purpose.

- Short bit lifespan: Diamond drill bits are more expensive than regular bits, so maximizing their life is important. Avoid using them at high speeds or with excessive force. If you notice the bit wearing out quickly, check if you’re using the right type for the material and whether you’re drilling dry or wet. Dry diamond bits are designed for dry drilling, but most diamond core bits last longer with some cooling.

- Difficulty removing core: When drilling with diamond core bits, sometimes the core gets stuck inside. Tapping the bit gently or using a thin tool can help remove it. Some bits glass or bits stone kits come with a tool for this purpose.

When to consider replacement or upgrade

If you notice your diamond drill bit is taking much longer to drill, or if the price of replacement is less than the time and effort spent on a worn bit, it may be time to invest in a new bits set. Keep an eye on price sale offers or kits that include multiple pcs and sizes, as these can offer better value than buying individual bits at regular price. Always compare price diamond and price regular to ensure you’re getting the best deal, especially if you frequently work with hard materials like granite or porcelain. Remember, using the right diamond core drill bits and maintaining them properly will save you both time and money in the long run, whether you’re drilling glass, tile, or stone.Maintaining and storing your diamond drill bits

Cleaning and Caring for Your Diamond Drill Bits

After each drilling session, it’s important to clean your diamond drill bits thoroughly. Residue from materials like glass, tile, or stone can clog the diamond surface, reducing cutting efficiency. Rinse the bits under running water and use a soft brush to remove debris. For stubborn material, soaking the bit in water can help loosen particles. Avoid using harsh chemicals, as they may damage the diamond coating or the bit’s core.

Proper Storage to Extend Bit Life

Store your diamond drill bits in a dry, cool place. Moisture can cause rust on the metal core, especially if the bits are not fully dry after cleaning. Many bits kits come with a case or holder—use these to keep your bits organized and prevent them from knocking against each other, which can chip the diamond surface. If you have a bits set with various sizes, keep them separated to avoid confusion and damage.

Inspecting for Wear and Damage

Before and after each use, inspect your bits for signs of wear. Look for dullness on the diamond surface, cracks in the core, or uneven wear. Using a damaged bit can lead to poor drilling results or even breakage, especially when working with hard materials like granite or porcelain. If you notice significant wear, it may be time to replace the bit, even if it was purchased at a sale price. Regular inspection helps you get the most value from your investment, whether you bought a single core bit or a full bits kit.

Tips for Maximizing Bit Longevity

- Use the correct speed and pressure for each material—drilling too quickly or with too much force can wear out the diamond surface faster.

- Let the bit cool between uses, especially with dry diamond drilling. Overheating can reduce the lifespan of both the diamond and the core.

- For wet drilling, always ensure adequate water flow to keep the bit cool and flush out debris.

- Rotate your bits if you have a bits set, so wear is distributed evenly across your collection.

Comparing Maintenance Needs: Diamond vs. Regular Drill Bits

Diamond drill bits require a bit more care than regular drill bits, especially when used on hard materials like tile, sea glass, or stone. While regular bits may only need occasional sharpening, diamond bits rely on the integrity of their abrasive surface. Investing time in proper maintenance can help offset the higher price diamond bits often command, making them a cost-effective choice over time. Whether you bought your bits at regular price or found a price sale, good care ensures you get the best performance and value from your diamond core bits and accessories.