Understanding brad point drill bits

What Makes Brad Point Drill Bits Unique?

Brad point drill bits stand out in the world of tools for their specialized design. Unlike standard twist bits, a brad point bit features a sharp, pointed tip—often called the "brad"—that helps guide the bit precisely where you want to start drilling. This tip reduces wandering, making it easier to create clean, round holes, especially in wood. The cutting edges on either side of the point slice through the material, while the spurs on the edge ensure a crisp entry and exit. This design is particularly valued by woodworkers and DIY enthusiasts who want outstanding performance and accuracy from their cordless drill set.

Key Features and Materials

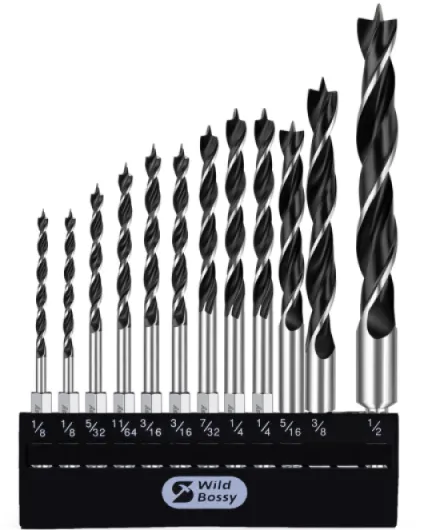

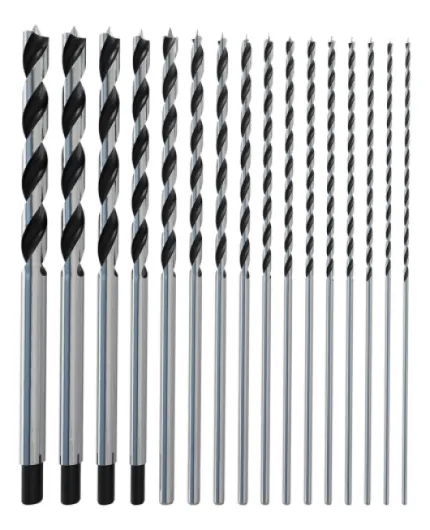

Brad point drill bits come in a variety of materials and finishes. High speed steel is common for durability, while titanium coated bits offer extra longevity and resistance to heat. Some sets include metric brad point drills for precise sizing, and you’ll find both hex shank and round shank options. Hex shanks provide a secure grip in your drill, reducing slippage, while round shanks are compatible with most standard chucks. The count in a set can vary, so consider what you need for your projects. Many products come in a metal case for easy storage and protection.

Why Choose Brad Point Bits for Woodworking?

These bits are especially effective for drilling into wood, plywood, and some plastics. The brad point ensures the bit stays centered, preventing the bit from skating across the surface. This is crucial for tasks where precision matters, such as cabinetry or furniture making. If you’re looking for more guidance on selecting the right drill bits for tougher materials like steel, check out this helpful guide on choosing drill bits for hardened steel.

What to Look for in Product Reviews

When shopping for a brad point drill bit set, pay attention to customer reviews. Look for feedback on the bit’s cutting performance, durability, and how well the edge stays sharp after repeated use. Price reviews can help you balance quality and budget, and some brands like bits fisch are known for their reliability. A well-reviewed set brad point drill bits can make a big difference in your cordless drill set’s versatility and performance.

Benefits of using brad point drill bits with cordless drills

Why brad point bits excel with cordless drills

Brad point drill bits are designed specifically for precision and control, making them an outstanding choice for cordless drill sets. The sharp brad point at the tip helps the bit stay exactly where you want it, reducing wandering and ensuring clean, round holes in wood and other soft materials. This is especially important when using a cordless drill, where stability and accuracy can be more challenging compared to a drill press.

- Clean entry and exit: The cutting edge and point design minimize splintering, giving you neat holes with minimal tear-out.

- Efficient drilling: Brad point bits require less pressure, which helps preserve battery life on your cordless drill and reduces user fatigue.

- Versatility: These bits are available in various shank types, including hex shank and round shank, allowing compatibility with most cordless drills and quick-change chucks.

- Material options: From high speed steel to titanium coated and metric brad point bits, there’s a product for every project and price point.

Customer reviews often highlight the outstanding performance of brad point bits in cordless drill sets, especially when drilling into wood. The precise design of the brad point and cutting edge ensures that even less experienced users can achieve professional results. For those interested in learning more about how different drill bits work together, understanding countersink and drill bit for cordless drill sets can provide additional insights.

When comparing sets, pay attention to the count, material, and whether the bits come in a metal case for protection. Brands offering bits fisch, titanium coated, or high speed steel options often receive positive price reviews for their durability and value. Ultimately, choosing the right brad point drills will help you get the most from your cordless drill set, whether you’re working on furniture, cabinetry, or general woodworking projects.

Choosing the right brad point drill bits for your cordless drill set

Key factors to evaluate before buying brad point drill bits

When selecting brad point drill bits for your cordless drill set, it’s important to look beyond just the price. The right bit can make a significant difference in the quality of your work, especially when drilling clean, round holes in wood. Here are some essential aspects to consider:

- Material and coating: High speed steel (HSS) is a common choice for durability and outstanding performance. For extra longevity, consider titanium coated bits, which resist heat and wear. Some premium sets, like bits fisch, offer specialized coatings for even greater edge retention.

- Shank design: Brad point drill bits come with either a round shank or a hex shank. Hex shank bits provide a more secure grip in your cordless drill, reducing slippage, especially at high speeds. This is particularly useful if you’re working with a powerful drill or tackling tougher materials.

- Bit count and sizes: Sets vary in the number of bits included. A metric brad point set with a wide range of sizes ensures you have the right tool for any job, from delicate pilot holes to larger round holes for hardware installation. Check the count and size range before purchasing.

- Cutting edge and point design: The sharpness and geometry of the brad point are crucial for precise starts and minimal tear-out in wood. Look for bits with a well-defined center point and clean cutting spurs along the edge for smooth, accurate holes.

- Storage and organization: A metal case or sturdy plastic box helps keep your bits organized and protected. This is especially valuable if you transport your tools frequently or want to extend the life of your set brad.

- Customer reviews and product reputation: Reading price reviews and customer feedback can reveal insights about real-world performance, durability, and value. Look for consistent praise regarding the bit’s ability to drill clean holes, maintain sharpness, and fit securely in your drill.

Matching your brad point bits to your cordless drill’s capabilities is also key. For example, if you use a high-powered model with a 36 V Li-ion battery, you’ll benefit from bits that can handle higher torque and speed. For more on optimizing your cordless drill set, check out this guide on how a 36 V Li-ion battery can transform your cordless drill set experience.

By weighing these factors, you’ll be better equipped to choose a brad point drill bit set that delivers reliable, clean results and stands up to repeated use in your woodworking projects.

Common applications for brad point drill bits

Where Brad Point Drill Bits Shine in Everyday Projects

Brad point drill bits are a top choice for anyone working with wood, thanks to their unique design. The sharp brad point at the tip allows for precise positioning, so you can start holes exactly where you want them. This is especially useful when accuracy is critical, such as when assembling furniture, installing hardware, or making cabinetry.

- Furniture assembly: The clean, round holes created by brad point bits help ensure tight joints and a professional finish. Whether you’re using a hex shank or round shank, the bit stays steady and reduces wandering.

- Cabinet making: These bits are ideal for drilling shelf pin holes or pilot holes for screws. The sharp edge and cutting spurs minimize tear-out, even in hardwoods.

- Woodworking crafts: For projects like toy making or decorative boxes, the outstanding performance of brad point bits means you get smooth, splinter-free holes every time.

- DIY home repairs: When you need to install hinges, handles, or other hardware, the precise entry point and clean hole make your work look more professional.

Many cordless drill set users appreciate the versatility of brad point drill bits. They’re available in various materials, including high speed steel and titanium coated options, which can affect both durability and price. Some sets come in a metal case for easy storage, and you can find metric brad point drills for projects that require specific measurements.

Customer reviews often highlight the value of a good set brad point drill bits, especially when compared to standard twist bits. The difference is clear when you look at the edge quality and the round holes produced. For those who work with different types of wood, investing in a product with a range of bit sizes and shank types—like hex or round—can make a big difference in your toolkit.

While brad point bits are mainly designed for wood, some high speed steel or titanium coated versions can handle light plastics. However, they’re not recommended for metal. For more demanding tasks or specialty materials, reviews suggest considering bits fisch or other premium brands, though price reviews can help you find the right balance between cost and performance.

Maintenance and care for brad point drill bits

Keeping Your Brad Point Drill Bits in Top Shape

Proper care and maintenance are crucial for ensuring your brad point drill bits deliver outstanding performance and last as long as possible. Whether you have a set brad in a metal case or a loose collection of bits, following some basic steps can help you get the most from your tools and protect your investment.

- Clean After Each Use: Wood dust and debris can build up on the cutting edge and shank. Wipe your bits with a dry cloth after drilling to prevent residue from hardening and affecting the bit’s design.

- Inspect for Damage: Regularly check the brad point and cutting edges for chips or dullness. A sharp point bit is essential for clean, round holes in wood. If you notice wear, consider sharpening or replacing the bit.

- Store Properly: Use a metal case or a dedicated holder to keep your drill bits organized and protected. This prevents the shank and point from knocking together, which can cause nicks or misalignment.

- Lubricate When Needed: While brad point bits are mainly for wood, a light application of oil can help prevent rust, especially if your set includes high speed steel or titanium coated bits.

- Sharpen Carefully: If you have the right tools and experience, you can sharpen the brad point and cutting edges yourself. Otherwise, professional sharpening services can restore the bit’s performance.

Customer reviews often mention that well-maintained bits fisch or metric brad sets provide more precise results and better value for the price. Taking care of your tools not only extends their life but also ensures you get clean, accurate holes every time you use your cordless drill. Remember, a little attention goes a long way in keeping your drill bit set ready for any project.

Troubleshooting drilling issues with brad point drill bits

Identifying Common Drilling Problems

Even with high quality brad point drill bits, users sometimes face issues when drilling into wood or other materials. Recognizing these problems early can help you maintain outstanding performance and extend the life of your drill bits and cordless drill set.

- Wandering or Skating: If the bit moves off the mark before biting into the material, check the sharpness of the brad point. A dull point or worn cutting edge can cause this. Using a center punch or marking the spot can help the bit start accurately.

- Rough or Splintered Holes: Brad point bits are designed for clean, round holes, but dull edges or excessive speed can cause splintering. Ensure your bit is sharp and use the right speed for the material. For soft woods, a slower speed often yields better results.

- Burn Marks on Wood: Overheating from high speed or a dull bit can leave burn marks. Try reducing drill speed and check if the bit needs sharpening. Bits made from high speed steel or titanium coated options tend to resist heat better.

- Bit Stuck in Material: This can happen if the flutes clog with debris or if the bit is forced. Withdraw the bit regularly to clear chips, especially when drilling deep holes.

- Wobbling or Oversized Holes: Using the wrong shank type (hex shank vs. round shank) for your drill chuck can cause instability. Ensure the bit is properly seated and compatible with your drill. Metric brad point bits and sets with precise sizing help avoid this issue.

Quick Fixes and Preventive Measures

- Regularly inspect your bits for wear, especially the brad point and cutting edges.

- Choose the right bit material for your project—speed steel and titanium coated bits offer durability for frequent use.

- Store your set in a metal case to protect the bits from damage and keep them organized by size and type.

- Read customer reviews and price reviews before purchasing a new set brad or individual bits to ensure you’re getting a reliable product.

- For stubborn issues, consider professional sharpening or replacing the bit if it’s beyond repair.

By understanding these troubleshooting steps and applying proper maintenance, you can ensure your brad point drill bits deliver precise, clean holes and outstanding performance for all your woodworking and DIY projects.