Summary

Editor's rating

Value for money: pricier than cheap sets, but you feel where the money goes

Design: split points that actually stay where you put them

Materials: real M35 cobalt, not just a fancy coating

Packaging and case: bits are good, box feels a bit cheesy

Durability: hold up well, as long as you don’t abuse them like crazy

Performance on real metal: where they actually shine

What you actually get in the box

Pros

- Cuts steel and stainless much better than basic HSS or titanium-coated bits when used at proper speed

- M35 cobalt material holds an edge longer and tolerates heat better, so bits last more jobs

- Full 29-piece index with 1/64" increments from 1/16" to 1/2" is handy for precise work and tapping

Cons

- Metal case feels flimsy and the smallest bits can come loose or fall out in transport

- Small-diameter bits still break if side-loaded or abused, despite the cobalt material

Specifications

View full product page →| Brand | IRWIN |

| Material | Cobalt |

| Finish Type | Cobalt Alloy Steel |

| Shank Type | Split Point |

| Cutting Angle String | 135 Degrees |

| Item dimensions L x W x H | 11.6 x 12.3 x 3.4 inches |

| Tool Flute Type | Spiral |

| Point Style | Brad Point |

Cobalt bits that actually cut, not just smoke

I picked up this IRWIN 29‑piece M35 cobalt drill bit set (model 3018002) because I was tired of burning through cheap titanium-coated bits every time I touched stainless or hardened bolts. I work mostly in a home garage setup, with the occasional job on equipment and a bit of fabrication, so I needed something that could handle real metal, not just sheet metal and pine 2x4s. On paper, these bits are made from M35 cobalt alloy, full index from 1/16" to 1/2" by 1/64", and aimed at drilling tougher steels. That matched exactly what I needed.

Over a few weeks, I used them on mild steel plate, angle iron, some old Grade 8 bolts, and a bit of stainless flat bar. I ran them in a corded drill, a cordless drill, and a small drill press. I used cutting oil most of the time, and I also deliberately abused a couple of sizes dry and too fast, just to see how they behaved compared to my usual budget sets. So this isn’t lab testing, it’s just real garage use with a mix of careful and careless drilling.

The main thing I noticed right away: these actually bite into steel instead of skating around and squealing. With the 135° split point, they start cutting a lot easier than the random hardware-store bits I had before. When I slowed the RPM down and added a bit of pressure, they pulled long curls from the metal instead of dust or blue chips, which is usually a good sign that the bit is doing its job and not just rubbing.

They’re not perfect. The bits themselves feel solid, but the case feels cheap and fiddly, and the smallest bits don’t stay put very well. Also, if you abuse them badly enough—too fast, no lube, hard material—you can definitely cook or snap them, they’re not magic. But overall, as a normal DIY/mechanic user, I’d say they’re pretty solid bits for real metal work, a clear step up from the usual bargain sets.

Value for money: pricier than cheap sets, but you feel where the money goes

Price-wise, this IRWIN cobalt set sits well above the bargain-bin drill bit kits, but below the ultra-premium industrial brands. For a 29-piece M35 cobalt set, the cost is not trivial, but you’re paying for actual performance on steel and stainless, not just a fancy coating and a big logo. If you mostly drill wood and plastic, this is overkill. But if you regularly deal with steel, rusted fasteners, or stainless, the higher price makes more sense.

For me, the value shows up in fewer ruined bits and fewer half-finished holes. With cheap bits, I’d often end up making an extra trip to the hardware store after snapping or burning a couple of sizes. With this set, I can usually finish the job with what I have, and the bits stay sharp long enough that I’m not constantly replacing them. Over time, that saves both money and frustration, even if the initial hit is higher.

Compared to other mid-range cobalt sets I’ve seen locally, this IRWIN set is pretty solid value. You get the full 1/64" increment range, which a lot of cheaper sets skip, and the material quality feels genuinely better than generic “cobalt” or “titanium” sets that are really just coated HSS. The main area where you feel the cost-cutting is the case, not the bits themselves, which is honestly the way I’d rather have it if something has to give.

If you’re a professional machinist, you might still prefer higher-end brands with even tighter tolerances and a heavier-duty case. But for a home shop, serious DIY, or mechanic use, I’d say the price is justified if you actually use them on metal. If you only drill a few holes a year, you can get by with cheaper bits. If you’re regularly fighting with steel and bolts, this set starts to look like a sensible long-term buy rather than a splurge.

Design: split points that actually stay where you put them

The key design element on these IRWIN bits is the 135° split point tip. In practice, that means the bit doesn’t skate all over the metal when you first touch down. On flat mild steel plate, I could start holes with light pressure and no center punch and still keep the bit roughly where I wanted. On round surfaces like bolts or pipe, I still used a punch, but even there, they walked a lot less than my older 118° cheap bits. That alone saves time and nerves when you’re working in awkward spots.

The flutes are pretty standard spiral flutes, not overly aggressive. Chip evacuation was good in mild steel and okay in stainless, as long as I didn’t choke the bit in deep holes without backing out. On a 3/8" hole through 1/4" mild steel, the bit pulled long, continuous spirals when I kept the speed low and used cutting oil. When I rushed it and went faster, the chips got shorter and bluer, which is normal, but you can tell these are designed to be run slower and with pressure rather than just spun as fast as your drill goes.

Length-wise, they’re typical jobber bits. In tight spaces, they’re not stubbies, so you’ll still fight clearance like with any normal bit. The shanks are not reduced except on the larger sizes where needed, so some of the bigger bits might be a no-go in drills with smaller chucks. In my 3/8" cordless drill, I maxed out at 3/8" bits; for 7/16" and 1/2", I used the drill press with a 1/2" chuck and had no issues there.

From a practical angle, the heavy-duty web construction (thicker core) makes them feel more rigid. The smaller bits still snap if you side-load them, but they didn’t feel as flimsy as super cheap HSS bits. Overall, the design is pretty straightforward: no gimmicks, just a focus on a solid tip geometry and a stiffer core so they can hold up in tougher materials.

Materials: real M35 cobalt, not just a fancy coating

IRWIN advertises these as M35 cobalt alloy steel, which usually means around 5–8% cobalt mixed into high-speed steel. That’s different from the common “titanium” bits you see everywhere, which are often just normal HSS with a titanium nitride coating that wears off quickly. With M35, the cobalt is in the steel itself, so even after multiple sharpenings, the base material is still heat-resistant and hard, not just the outer surface.

In use, that shows up mostly in how they handle heat. When I drilled into stainless flat bar at low speed with cutting oil, the bits stayed sharp and didn’t blue as fast as my cheap set. On purpose, I abused a 1/4" bit by running it too fast, dry, into a piece of angle iron. It did get hot and slightly discolored, and it lost some bite, but it didn’t totally die like budget bits usually do. After a quick touch-up on a drill bit sharpener, it was usable again. So the material gives you a bit more margin before you cook the cutting edge.

Another thing I noticed is edge retention. I used one 3/16" bit to drill out a couple of broken bolts on a truck frame. Normally with my old HSS set, the bit would start rubbing and squealing halfway through the second bolt. This one kept cutting, as long as I stayed patient with speed and pressure. After that, the edge was still decent enough for more light work without immediate sharpening.

They’re still steel, not carbide, so if you hit hardened areas, welds, or do something really abusive, you can chip or dull them. But for normal steel, stainless, and tougher alloys that kill regular bits, the M35 material feels like a genuine upgrade. You’re paying for better steel, not just a pretty finish, and in practice that does show during heavier drilling jobs.

Packaging and case: bits are good, box feels a bit cheesy

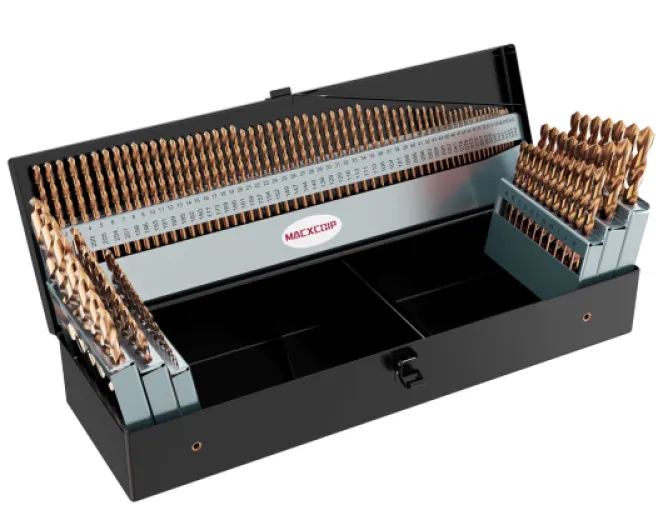

Packaging is pretty basic: cardboard outer packaging and then the metal index case that actually matters. There’s not much to say about the cardboard; it does its job for shipping and then goes in the trash. The real talking point is the metal case that holds the 29 bits. On the plus side, it’s compact, all the sizes are clearly marked, and the flip-out index makes it easy to see and grab the size you need without digging through a pile of loose bits.

On the downside, the case itself feels a bit flimsy compared to the price of the set. The metal is thin, the latch doesn’t inspire a ton of confidence, and the smallest bits don’t always stay firmly in their slots if the case is bounced around. One of the Amazon reviewers called the case “chintzy,” and I think that’s fair. It looks like the manufacturer tried to make it look professional without spending much on the actual hardware of the box.

In daily use, it’s fine if you store it upright on a shelf or in a drawer. If you toss it in a truck box or let it rattle in the back of a van, you’ll probably open it to find a couple of the tiny bits loose in the bottom. The bigger bits stay put better. I ended up slipping a small piece of foam in the lid to keep everything from jumping out when the case is jostled, which helped a lot. Not ideal, but it works.

So, packaging is functional but not impressive. The bits deserve a sturdier home, honestly. If you’re careful with your tools, this won’t be a huge issue. If you’re rough on gear or work on the road a lot, you may want to either baby the case or eventually move the bits into a better index box. The product itself is the steel, not the tin it comes in.

Durability: hold up well, as long as you don’t abuse them like crazy

In terms of durability, I’d say these bits are solid, but not indestructible. Over a few weeks, I used maybe 10–12 of the sizes regularly. None of the mid-size bits (1/8"–3/8") chipped or snapped under normal use. Edge wear was reasonable: after multiple holes in steel and some stainless, they still cut without needing constant sharpening. That’s a big step up from generic sets where you basically throw the bit away after a couple of harder jobs.

The weak point, as usual, is the very small bits. The 1/16" and nearby sizes are always fragile, cobalt or not. I did snap one small bit when I twisted the drill slightly in a tight corner. That’s not unique to this set; any thin bit will do that. The good news is that the rest of the set has enough backbone that you don’t feel like you’re working with glass. The thicker web makes them feel more substantial, especially in the 3/16"–3/8" range.

Heat resistance is where the durability really shows. I deliberately drilled a series of holes in angle iron and didn’t let the bit cool much. With my old HSS bits, that usually leads to a blue, useless tip. Here, I got some discoloration, but the bit didn’t die instantly. It did lose some sharpness, but after a quick touch-up, it went back into rotation. So you do get more life out of each bit, especially if you’re willing to sharpen them now and then.

The only durability disappointment isn’t the bits, it’s the case. The hinge and latch feel cheap, and the smallest bits tend to jump out of their slots if the case gets knocked around in a toolbox. Over time, I can see the case bending or the latch wearing out. The bits will probably outlast the box. So in terms of long-term use, I trust the metal in the bits, but I don’t fully trust the storage to handle years of rough handling without some annoyance.

Performance on real metal: where they actually shine

Performance-wise, these bits do what they’re supposed to do on tough metal. On mild steel (1/8" to 1/4" thick), they cut quickly and cleanly as long as I kept the RPM low and used even pressure. With cutting oil, holes came out smooth, and the bits didn’t squeal or chatter unless I got lazy and let the speed creep up. Compared to my older titanium-coated set, the difference was obvious: less heat, less wandering, and far fewer burned tips.

On stainless steel, which is usually where cheap bits go to die, they held up much better than I expected. I drilled several 1/4" and 5/16" holes in stainless flat bar and angle. Going slow, with oil, I got proper continuous chips, and the bits still felt sharp afterward. When I pushed my luck and tried dry drilling a couple of holes at higher speed, I could feel the cutting edge dulling a bit, but they still finished the job without completely rounding over.

Where they impressed me the most was drilling out old, hardened bolts on a vehicle frame. I used a series of bits, stepping up from a small pilot hole to the final size. Normally, this is where bits snap or glaze over. The IRWIN bits stayed controllable, and I only broke one small-size bit, which was my fault for side-loading it in a cramped spot. The bigger sizes stayed intact and kept cutting. That’s the main reason I’d keep this set around: they make ugly repair jobs a lot less painful.

They’re not magic bullets. If you run them too fast, with no lube, into thick material, you can still cook them or even split a larger bit. But if you use them halfway correctly—slow speed, some oil, and proper pressure—they hold their edge and get through jobs that cheaper bits struggle with. For someone who actually drills metal more than wood, that’s basically what matters.

What you actually get in the box

Out of the box, you get a metal index case with 29 bits, from 1/16" up to 1/2" in 1/64" increments. So if you’re doing more precise work, tapping threads, or trying to hit specific hole clearances, the size coverage is actually very handy. It’s a proper jobber-length set, so nothing odd in terms of length or weird shanks. They’re standard round shank bits, so they fit fine in regular drill chucks and my small drill press. No hex shank gimmicks here.

The case itself is a painted metal box with a swing-out index. Sizes are stamped into the metal rows and are reasonably easy to read when the case is clean. After a few greasy sessions, the markings are still visible, but you do need decent light. The lid closes with a simple latch. It’s not fancy, but it does keep everything together and is better than the flimsy plastic clamshells a lot of cheaper bits come in. Still, the overall feel of the case is a bit “budget shop” compared to the quality of the bits inside.

Each bit comes with a 135° split point, which is the important detail here. That’s what helps them start on contact and cut with less wandering. There’s no special coating color like bright gold or rainbow nonsense; they just look like plain high-speed steel with a slightly different tone from the cobalt content. If you’re used to shiny titanium-coated sets, these might look boring, but they’re clearly built more for function than for shelf appeal.

Overall, the presentation is practical: a full range of sizes, clear labeling, and a metal case that fits in a drawer or on a shelf without taking up too much space. Visually, nothing flashy, but from a working perspective, it’s what you need: all the common sizes in one place, ready to go. Just don’t expect the box to feel as tough as the bits themselves.

Pros

- Cuts steel and stainless much better than basic HSS or titanium-coated bits when used at proper speed

- M35 cobalt material holds an edge longer and tolerates heat better, so bits last more jobs

- Full 29-piece index with 1/64" increments from 1/16" to 1/2" is handy for precise work and tapping

Cons

- Metal case feels flimsy and the smallest bits can come loose or fall out in transport

- Small-diameter bits still break if side-loaded or abused, despite the cobalt material

Conclusion

Editor's rating

Overall, the IRWIN 29-piece M35 cobalt drill bit set is a solid choice if you actually drill metal on a regular basis. The bits bite into steel and stainless much better than the usual budget HSS or titanium-coated sets. The 135° split point makes starting holes easier with less wandering, and the M35 cobalt material holds an edge noticeably longer, especially when you use proper speed and cutting oil. In real use, that means fewer burned tips, fewer snapped mid-size bits, and less swearing when you’re trying to drill out a rusted bolt or go through thicker steel.

It’s not perfect. The case feels cheap for the price, and the smallest bits can still snap if you’re rough or side-load them. You can also ruin these if you abuse them badly enough—run them too fast, no lube, into tough material—and they’re not going to magically survive everything. But for the average home mechanic, fabricator, or serious DIY person, they hit a good balance of performance and cost. If you mostly work on wood or only drill metal once in a blue moon, you can probably save money and go with something simpler. If metal is part of your regular workload and you’re tired of smoking cheap bits, this set is good value and holds up well in real-world use.