Understanding Cordless Drill Set Features

Exploring Essential Features of Cordless Drill Sets

In the realm of power tools, understanding the features of a cordless drill set is crucial for making informed decisions. With advancements in technology, these tools have evolved significantly, offering an array of features that enhance their efficiency and ease of use. One of the primary features you should consider is the power output, often measured in maximum voltage, such as the Dewalt max or Milwaukee's offerings. When comparing models, take note of the drill's speed settings, which can impact the versatility and suitability for different tasks. Generally, a drill with variable speed control can handle a wider range of projects. A brushless motor is another vital feature to watch out for, offering greater efficiency and longevity compared to traditional brushed motors. Brushless cordless drills, such as those in the cordless drill kit range, typically generate lower heat and are more energy-efficient, making them a popular choice among professionals and DIY enthusiasts alike. Battery technology is a significant factor influencing the performance and convenience of cordless drills. With the shift towards lithium-ion batteries, you'll find that modern drills offer longer runtimes and quicker charging times, allowing you to work uninterrupted. Consider the battery capacity, often indicated in amp-hours (Ah), and check if the kit includes spare batteries for seamless operation. The type of chuck and its size is also a noteworthy feature. A keyless chuck design allows quick and easy bit changes, while sizes like 1/2-inch and 3/8-inch cater to various applications and project needs. Additionally, impact drivers and hammer drills offer specialized functionality, with higher torque lbs and impact capabilities ideal for tougher materials. For those seeking a comprehensive solution, a driver kit equipped with various accessories can be valuable. Brands like DeWalt and Black Decker often include diverse tool sets that enhance the versatility of your power drill. To further explore these features, explore the details at exploring the versatility of power tools.Comparing Power Drills: Cordless vs. Corded

Cordless Convenience vs. Corded Power

When selecting the ideal power drill, the debate often boils down to cordless versus corded. Both have their unique advantages and challenges, tailored to specific projects and personal preferences.Mobility and Flexibility

Cordless drills, such as popular models produced by Dewalt and Milwaukee, offer an unrivaled level of mobility and flexibility. With no need for an electrical outlet, these tools are perfect for worksites that lack easy access to power. The inclusion of lithium-ion batteries in models like the max brushless drill driver ensures extended use without constant recharging. In comparison, corded drills benefit from a continuous power supply, suitable for tasks requiring sustained energy output. These are ideal when stationary working conditions allow, such as in a workshop setting.Power and Performance

Cordless drills provide significant advancements in power, with more sophisticated designs like the brushless motor offering enhanced performance and efficiency. Brands like Dewalt have capitalized on this, creating tools that pack a punch, notably the Dewalt DCD MAX series. The power in cordless drills has been boosted by improvements in battery technology, leading to increased torque lbs and higher operational speeds. On the other hand, corded drills deliver consistent power ratings, making them better suited for heavy-duty use and repetitive drilling tasks. This can be particularly helpful when using a hammer drill function, often found in cordless kits.Considerations for Choice

The decision on whether to go cordless or stay corded should factor in the nature of your projects. DIY enthusiasts may favor the cordless options for their ability to tackle a variety of locations effortlessly. For more exploring the versatility of power tools and their essential accessories, examining both types is vital. Ultimately, the choice often lies in the balance between the need for flexibility and power. For tasks like driving screws with an impact driver or using a chuck for fast bit changes, understanding what each type can offer will assist in making an informed decision.Battery Technology in Cordless Drills

Advancements in Battery Technology Transforming Cordless Drills

In recent years, battery technology has become a cornerstone of innovation in cordless drills, with advances enhancing both power and efficiency. The shift from traditional nickel-cadmium (NiCd) to lithium-ion batteries has significantly impacted the performance of these power tools.

Lithium-ion batteries have taken precedence because of their higher energy density, which allows them to hold more charge in a lighter, more compact form. This means that modern cordless drills, such as those offered in the Dewalt and Milwaukee ranges, can deliver more power without the need for bulkier designs. The Dewalt DCD series and Milwaukee drivers are prime examples where this technology shines, allowing for extended usage and faster charging times. These batteries often come with max capacity, offering the power drill user robust performance for more demanding tasks.

Another important consideration is the introduction of brushless motors, which work hand-in-hand with lithium-ion batteries. Brushless motors contribute to higher efficiency by regulating energy use, leading to longer battery life and increased tool longevity. For instance, a max brushless drill driver kit in a cordless set can deliver consistent torque and speed, essential for both simple modifications and more complex projects, like using an impact driver or cordless hammer drill.

The capacity and compatibility of the batteries are equally crucial, as different tools may require distinctive power levels. For example, a black decker power tool kit may be optimal for light household tasks, while a Dewalt volt tool dcd max series might be better suited for heavy-duty work.

With these advancements, the market now abounds with versatile options catering to various zip codes and applications. For those looking to further explore the best options available, consider checking out a comprehensive breakdown of top cordless drills for DIY enthusiasts.

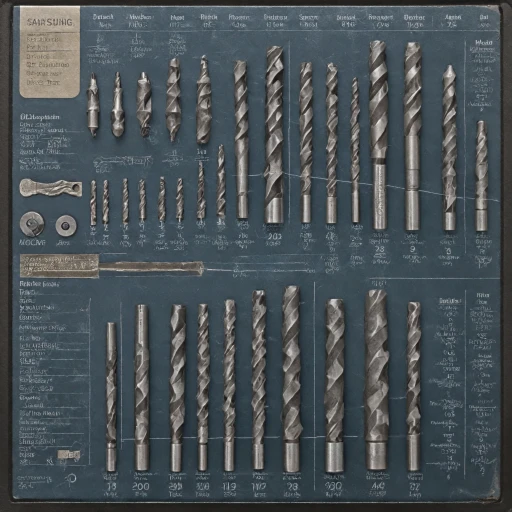

Selecting the Right Drill Bit for Your Project

Choosing the Perfect Drill Bit for Every Project

When tackling a project with your cordless drill, selecting the appropriate drill bit is crucial for achieving the desired results. Whether you're using a power drill from Dewalt, Milwaukee, or Black & Decker, understanding the connection between the drill, the bit, and the material is vital.

The drill bit serves as the intermediary tool that translates the drill's power into effective action. Here’s what you need to consider:

- Material Compatibility: Make sure your bit matches the material you're drilling into. For wood, use brad-point bits; for metal, cobalt or high-speed steel bits work best; and for masonry, opt for masonry bits designed for concrete or bricks.

- Size and Shape: The size of the bit will dictate the diameter of the hole. Always refer to your project specifications to ensure the correct size and shape of the bit, accommodating either a straight or tapered shaft.

- Bit Types: Tools like hammer drills can use specialized bits that withstand the additional force and vibration. Meanwhile, impact drivers often require shorter and more robust bits to handle torque.

- Bit Coating: Titanium coating can enhance the bit's lifespan when working with metal, while black oxide coatings are better suited for reducing wear on standard surfaces.

- Compatible Chuck Size: Ensure the bit’s shank matches your drill’s chuck size, whether it be 3/8 inch or 1/2 inch. Most cordless drill kits, like dewalt dcd models, come with adaptable chucks to accommodate varying shank diameters.

Understanding these factors can unlock the fullest potential of your chosen cordless drill, offering efficiency and precision in your tools' performance. Remember, your choice of drill bit is as integral as the drill itself when ensuring successful project execution with cordless hammer or brushless cordless drills.

Maintenance Tips for Longevity

Keep Your Drill in Peak Condition

Ensuring the longevity and efficient performance of your cordless drill set requires regular maintenance. Given the technological advancements in cordless designs, proper care translates to maintaining battery health, tool integrity, and mechanical endurance. Here are some practices that can help:

- Battery Maintenance: Since cordless drills like the Dewalt DCD models rely heavily on lithium-ion technology, it’s crucial to store batteries in a cool, dry place to prevent deterioration. Avoid overcharging by removing the battery once it is fully charged to extend its lifecycle.

- Clean Regularly: After every use, clean your drill and its components, such as the chuck and drill bits. Dust and debris can hinder performance, so ensure the power tool’s ventilation areas are unobstructed.

- Lubrication: The moving parts, especially in high-torque models like the Milwaukee and Black & Decker, need periodic lubrication to reduce friction. This not only helps in maintaining speed consistency but also in avoiding unnecessary wear.

- Tightening and Inspection: Routinely check the drill for loose parts, especially vital areas such as the chuck and connections in brushless motors. A quick inspection before use can prevent malfunctions, ensuring your tool’s effectiveness and safety.

- Storage: Proper storage in a tool kit or a dedicated space ensures your drill and its accessories remain intact. Make sure the environment is moisture-free to avoid corrosion not just on your power drill but on drill bits and impact drivers as well.

By following these maintenance steps, users can enhance the performance and lifespan of their cordless drill sets, whether seamlessly completing tasks with the Dewalt volt hammer drill or any other model. Staying proactive about maintenance is essential, reflecting on the insights shared in previous sections regarding battery technology and comparing power drills' advantages.

Safety Practices When Using Power Drills

Ensuring Safety with Your Power Tools

When it comes to handling power tools like cordless drills, whether it's a Dewalt, Black Decker, or a Milwaukee, prioritizing safety is essential. These powerful tools, equipped with features like brushless motors and lithium-ion batteries, demand a level of respect during use. Here are some key safety practices to keep in mind.- Proper Tool Selection: Ensure you're using the right tool for the job. Consider whether you need a driver kit, hammer drill, or impact driver, as using the wrong one can lead to injuries or damage.

- Inspect Before Use: Check your cordless drill set, including batteries, the chuck, and torque settings for any wear or damage. A malfunctioning component can cause unexpected accidents.

- Secure Work Environment: Make sure your workspace is organized and free of obstacles. Secure any materials you're working on to prevent slippage or movement while drilling.

- Personal Protective Gear: Always wear appropriate protective equipment. Safety glasses, gloves, and ear protection are foundational safety gear when operating drill drivers or any power tools.

- Right Speed for the Task: Adjust the speed setting on the drill to suit the material and bit you're using. High speeds can cause loss of control, especially with softer materials.

- Battery Safety: For drills with a Dewalt volt lithium-ion battery or similar, ensure you follow manufacturer instructions when charging. Overcharging or using incompatible chargers can lead to overheating or fire hazards.